Solder Sucker

erco

Posts: 20,263

erco

Posts: 20,263

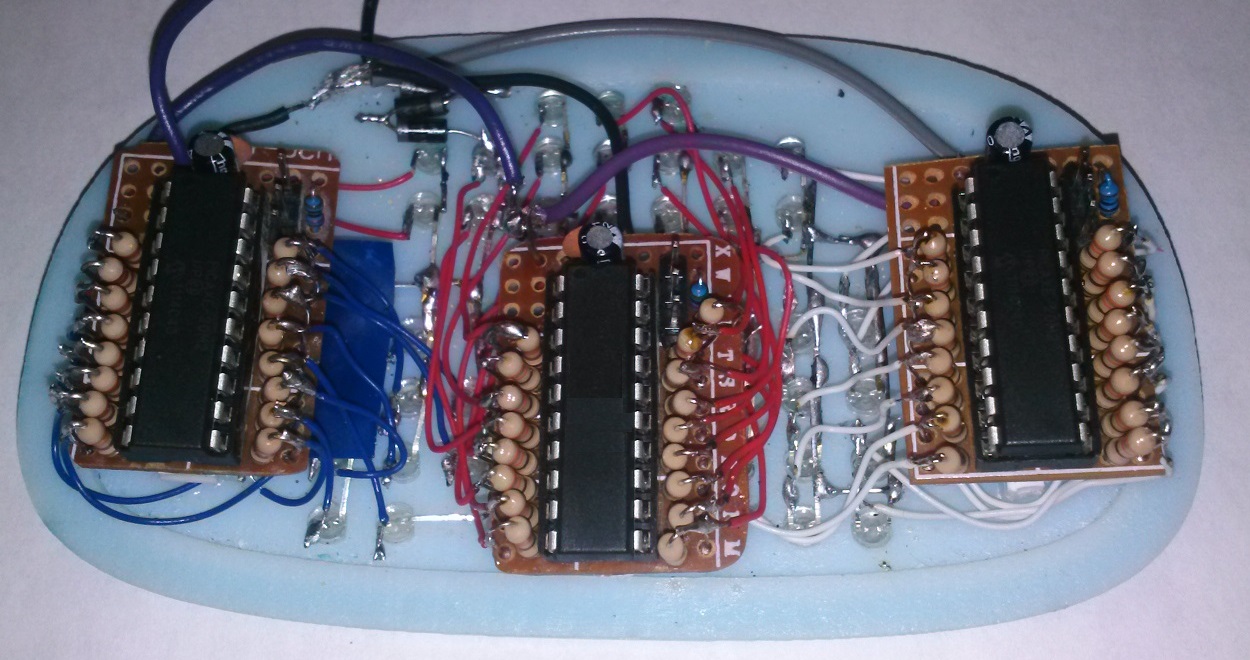

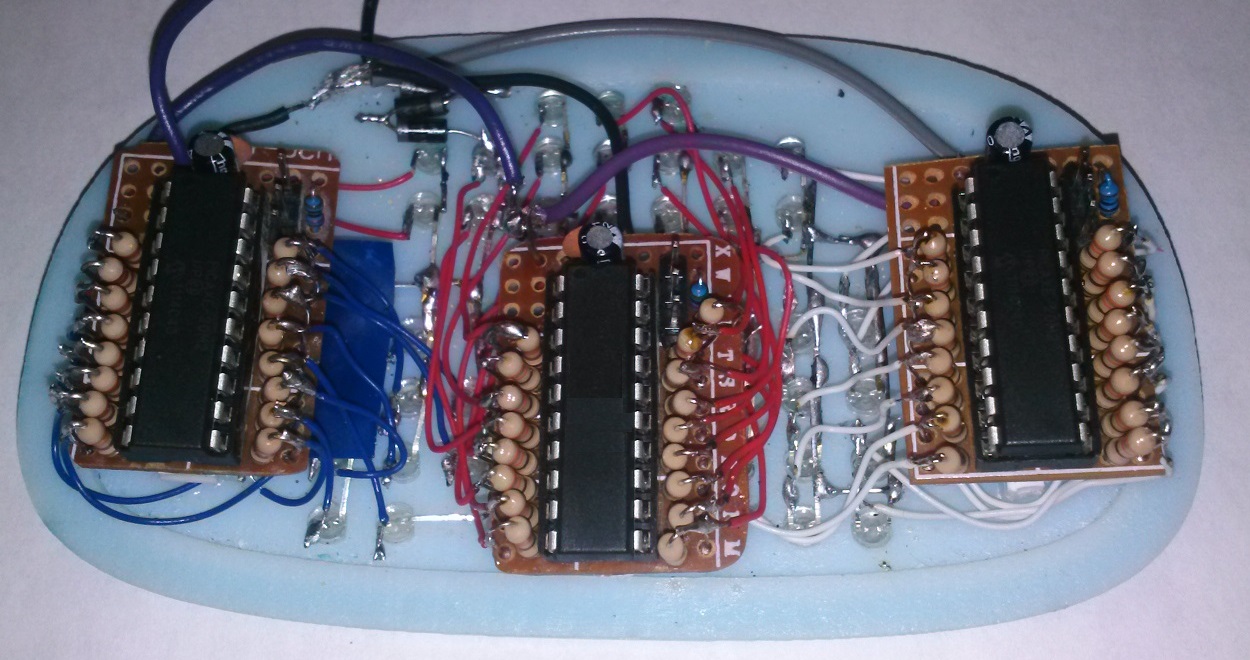

I'm talking about ME, not a desoldering tool. As in, I'm a sucker for soldering. In the middle of building 3 uC boards and wiring up a custom 46-LED array last night, I realized how much fun I was having. Prolly not my healthiest activity still using leaded solder, but I find it enjoyable and gratifying to build hardware, so it's good for my mental health anyway. Just like using my hands I guess. I don't even mind building the same uC board over & over. It's still a kick when it all works the first time. Well nearly, I had one bad LED I had to replace.

TTYTT, I even enjoyed drilling out those 46 LED holes by hand.

Am I completely sick?

TTYTT, I even enjoyed drilling out those 46 LED holes by hand.

Am I completely sick?

Comments

"Am I completely sick?"

Not in my estimation. I find the occasional long repetitive task that requires precise work very relaxing. The electronic equivalent of building a ship in a bottle. Some of my early work involved desoldering all the joints on a motherboard and all the daughterboards and then resoldering them to get rid of all the cold solder joints. Very relaxed after a day doing that.

Now the same thing goes together in far less time, using the breakout and a resistor network.

Never again!

As to leaded solder: meh! I've worked around lead, both soldering and casting, for more than 50 years. Ain't dead yet!

-Phil

Woulda been nice, but these were 0.250" centers. Graph paper was my friend! I'm pleased, it came out quite nice.

Yes, but more obvious is your signs of insanity...

Nice work. As others have said, sometimes, that long tedious amount of soldering is very enjoyable. As seen here: http://forums.parallax.com/discussion/comment/890109/#Comment_890109

Unless your iron is running over 1700C, you have no worry for lead poisoning during soldering.

Half the strain of hours of soldering, was holding my breath when I had to be real close to my work.

Oh but that smell, it warms the heart and soul.

-Phil

There are those that say that lead absorption through the skin could be a problem. I suspect that amounts to less lead exposure than all the lead we were breathing in from fuel additives for decades. Just wash you hands when done and don't be tempted to pull the solder straight with you mouth.

The flux can be annoying, but it's pretty easy to get a fan to disperse that.

I just spent a couple of relaxing hours building up the Evil Mad Scientist 555 Timer kit. It reminded me how much I enjoy soldering. It's kind of magical to see it working it's thing.

-Phil

I have this bad habit of using my mouth as a third hand to hold the solder.

Maybe I should get tested, or just stop doing that.

Never mind getting tested. You won't like the results and there is probably not much they can do about it

I started using a bit of shrink tube to put over the solder when it's in my mouth. The tubing is always within reach.

Now I'll get plastic poisoning.

I don't think anyone has gotten sick from soldering. RoHS was about keeping it out of the landfill. Unless you're producing and selling millions of units lead is great! Leaded solder with its lower melting point, and less flux fumes could actually be healthier.

That does not seem right. The vapor pressure of lead goes like this with temperature: According to this online calculator https://www.iap.tuwien.ac.at/www/surface/vapor_pressure

You found one of the Evil Mad Scientist kits! They have done some wonderful stuff.

Check out their latest project, the MOnSter 6502, which will be on display at the Maker Faire:

http://www.evilmadscientist.com/

Now I want to solder a circuit inside a bottle!

And those shiny volcano shaped solder joints.

I'm hoping to se the Monster6502 at the Maker Faire next week end.

@erco,

I think soldering up a circuit in a bottle is an excellent idea. I had previously considered some kind of circuit made from long thin PCBs that somehow plugged together when inside the bottle.

Actually soldering them up inside the bottle is an extra challenge!

The soldering tool and solder feed mechanism could be made. The trick is getting the PCB inside and keeping the parts in place. I suppose you could pre-assemble small PCB's that could then go in and be soldered together. Seems like cheating though.

Get the paella for lunch!! There's only one vendor who makes it, and it's done live onsite in huge shallow wok-like pots, it's excellent.

Are you attending the IOT show? Anything good there?

Not making the IoT event I'm afraid. We have had too much to do here.

Made my own soldering iron from a screw filed down and wound with enamelled copper wire and Telephone Batteries. The huge cylindrical 1V5 ones.

Done lots of hand soldering with leaded solder. I now have unleaded solder and solder paste. However I prefer leaded solder as it's easier for hand soldering.

I am still here and I can at least remember this, so hasn't been that bad for me.

Never let work get in the way of a good time.

Never let the truth get in the way of a good story.

This is the PCB you need:

Sounds like a Kickstarter idea: PCB in a bottle kit, includes wire feed soldering iron!

Tuesday, back to San Jose for some meeting or other.

So sadly the IoT event slipped out of the picture.