3D printed line follower (It Works!)

Getting close to finishing design of this 3D printed line follower...

Thought I'd post pictures, in case anybody has ideas on how to improve it...

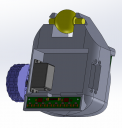

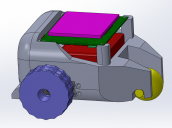

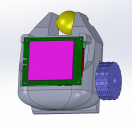

Going for what I guess I'd call a "unibody" construction where there is just one big piece to print.

Then, just need to print the wheels and the ball (third wheel).

The top circuit board is my own with 3.5" LCD, but is same size as Activity Board, so can use that if need to.

The bottom board is also a custom copy of Sparkfun's line follower array.

Thought I'd post pictures, in case anybody has ideas on how to improve it...

Going for what I guess I'd call a "unibody" construction where there is just one big piece to print.

Then, just need to print the wheels and the ball (third wheel).

The top circuit board is my own with 3.5" LCD, but is same size as Activity Board, so can use that if need to.

The bottom board is also a custom copy of Sparkfun's line follower array.

Comments

Added some holes for cables and sent to printer.

Printer says it's going to take 35 hours to print... That's a long wait!

I've had fun hacking some $5 line follower kits, I'm sure yours will beat those for speed!

Please give my regards to Northern Virginia! I was a Woodbridge kid. You're in Vienna IIRC.

But, I've also been in a competition at Parallax where there were junctions and they only told you which path to choose right before the race. So, all of those would fail horribly...

Do all finished products have that layered ribbing?

Does it ever de-laminate?

Can you get a smooth finish on a completed design?

I haven't done that though...

De-lamination and/or warping can happen on large parts, especially with ABS. PLA isn't as strong, but doesn't have this issue.

Had to restart chassis print this morning though as build plate was not level enough for this big print and made a mess.

Looking good now and total print time has updated to 19 hours.

I've been contemplating an ultrasonic acetone mister. If I could get my printer to do consistent overhangs...

Some acetone polishing here probably would reduce friction. But, I think it'll be OK as is.

You could use that, or print that type of snap-in holder on your chassis, sized to fit a ball bearing ($) or glass marble (very cheap). A great benefit of 3D printing is that you can print overhangs (AKA undercuts) which are impossible in injection molding without slides.

Robot is over 50% printed now. I probably should have only done 10% infill instead of 30%. That's probably one reason it's taking so long...

The ball wheel and the circuit board are retained by the plastic nibs, so that worked.

Only minor issue was with the bottom, it appears to have gotten real hot.

Maybe room was too cold and heated build plate worked too hard to compensate...

Might have been better to print with PLA where doesn't need heated build plate.

Anyway, it took an extra bit of work to remove the support from the bottom, especially where the line sensor array goes.

Now, I have to wait for my custom PCBs to get here...

Till then, I can use the Activity Board...

It was pretty tight up against the forward wall there...

The chassis used ~100 meters of a 240 meter filament spool (that costs $25).

So, that's about $10 in filament to print. Maybe $15 with wheels, tops.

I've read that my servos easily take 9 VDC.

With NiMH at 1.2V, six cells gets me to 7.2 V, which seems like a good place...

In addition to line following, this beauty looks like promising a figure 8 candidate!

Had to rotate the board 180 degrees though so could access USB port...

Modedit: YouTube link

http://www.thingiverse.com/thing:2322633

Does this work:

https://youtube.com/watch?v=r25Xge8_asM

Or maybe just start farther from the wall.

Great job!

Your gonna need a bigger arena, that bot was born to motivate.

Got a name in mind yet?