Radial Clock project

JasonDorie

Posts: 1,930

JasonDorie

Posts: 1,930

I'm kind of fascinated by cool clocks, and have long wanted to build one of the spinning POV types, but was never happy with the result (hard to tell the hours / mins / secs apart, noisy, etc). I recently bought a bunch a couple strips of DotStar LEDs and had another go of it. DotStar LEDs are like NeoPixels, but with a much higher update rate and more forgiving timing.

There are currently 60 LEDs around the outer edge in a circle, pointing inward. There will soon be another ring of 60 in the middle, pointing outward. The whole thing is driven by a Prop, using a DS1307 RTC to keep time. I only check the RTC once an hour, and just use the Prop's internal counters otherwise.

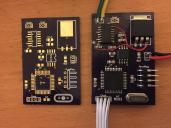

This is the first time I've ever made my own SMD board. I did the layout in DipTrace, sent the files off to OSH Park to make the boards. I applied solder paste by hand with a syringe, placed components with tweezers, and used a $30 electric skillet from Target to solder it up. Aside from a dumb design error, it worked. You can see the fix in the pictures - I had the level shifter connected to 3.3v instead of 5v.

The physical part of it is HDPE, cut on my CNC. I'm probably going to simplify the physical design quite a bit in the next version, and it's going to have a thin sheet over the front to diffuse the LEDs. I also want to have a photo-sensor to let it adjust to ambient light, and a means to set the clock (currently that's done in code, once, then the RTC battery keeps time when unpowered). I might do that with an IR remote, and use the same to allow you to change "modes" in the display. With 120 addressable RGBs there are lots of possibilities.

Here's a clip:

This is using PropGCC, and is currently just over 4kb, compiled.

There are currently 60 LEDs around the outer edge in a circle, pointing inward. There will soon be another ring of 60 in the middle, pointing outward. The whole thing is driven by a Prop, using a DS1307 RTC to keep time. I only check the RTC once an hour, and just use the Prop's internal counters otherwise.

This is the first time I've ever made my own SMD board. I did the layout in DipTrace, sent the files off to OSH Park to make the boards. I applied solder paste by hand with a syringe, placed components with tweezers, and used a $30 electric skillet from Target to solder it up. Aside from a dumb design error, it worked. You can see the fix in the pictures - I had the level shifter connected to 3.3v instead of 5v.

The physical part of it is HDPE, cut on my CNC. I'm probably going to simplify the physical design quite a bit in the next version, and it's going to have a thin sheet over the front to diffuse the LEDs. I also want to have a photo-sensor to let it adjust to ambient light, and a means to set the clock (currently that's done in code, once, then the RTC battery keeps time when unpowered). I might do that with an IR remote, and use the same to allow you to change "modes" in the display. With 120 addressable RGBs there are lots of possibilities.

Here's a clip:

This is using PropGCC, and is currently just over 4kb, compiled.

Comments

Or if you really like color, turn off the segments representing the hands, and all the rest are colors.

Ever see an Aurora clock?

I hadn't seen an aurora clock until I went googling for it. The mode in the video is only one of them. The "default" mode is exactly what you say - H/M/S each have their own color, and the colors blend when they overlap. I also make them different widths to help differentiate them. The clock hardware supports two rings of LEDs, and I have another one to mount - the inner ring will be hours, the outer ring will be minutes and seconds, much like a traditional clock.

The "sparkle" mode (in the video) maintains a fixed brightness but slowly and randomly moves pixel colors around. I also want to do a version where the background is fixed to a single color (probably white) and let you choose the intensity of it, so you could use it as a room or reading light as well as a clock.

Mostly I made it as a test of skillet soldering. I've always been a little intimidated by SMD stuff. Having done it, it really isn't that bad.

That'some nifty tooling.

Interesting idea. Could make it easier to read, at the expense of 2x the LED count.

Even 12 on the inner led could be useful, at a reduction in cost ?

How many LEDs in the rings ?