P123-A7 power supply issue (Fixed! [I think])

I've already mentioned this in a couple threads, but just want to show a cool picture...

The issue is that the power supply goes bananas when first turned on (blue power light flickering).

Then, after a couple minutes it's fine.

So, I don't really have a big issue and I'm not asking Parallax to do anything about it.

Anyway, I'm trying to diagnose it myself with FLIR Lepton thermal imager connected to P1.

This hasn't helped yet, but it's pretty neat.

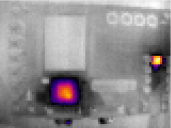

Here's a snapshot of the P123 board (you can see Cyclone and something in the power supply are the hot things):

The issue is that the power supply goes bananas when first turned on (blue power light flickering).

Then, after a couple minutes it's fine.

So, I don't really have a big issue and I'm not asking Parallax to do anything about it.

Anyway, I'm trying to diagnose it myself with FLIR Lepton thermal imager connected to P1.

This hasn't helped yet, but it's pretty neat.

Here's a snapshot of the P123 board (you can see Cyclone and something in the power supply are the hot things):

Comments

I'm looking around my P123, but don't see anything.

Was worth a shot anyway...

One corner of the Cyclone looks warm, did you have just one or two cogs running when you took the image?

Or is it the egg-beater hub?

Aside from it not helping with your power issues, thermal imaging from a P1 is pretty darn cool!! It looks like you have enough pixel resolution across something the size of a 1-2-3 board to do some useful things. Certainly another fun Propeller avenue to explore!

It does have P2 firmware, but isn't running any Prop code...

I wonder if it is where the hub egg-beater is located in the fpga image? Might be interesting to know at some point?

I will find out where those resistors are and what value is more ideal, so that anyone can change them if they want to.

What drives the LED ? just a Series R from Vcc ?

Flickering suggests wide Vcc fluctuation in that case.

What does a scope show ?

I'd be a tad worried about AC modulation peaks damaging the FPGA.

That camera is really neat! Does it use any lens, or would one interfere with the heat?

The additional lenses or windows do have to be a special material to transmit between 8 and 12 um.

The options I know of are ZnSe, Silicon and Germanium.

ZnSe is a pretty standard thing you can buy

I'm seeing something else too. If I set LCD backlight to full on (I think ~400 mA from 3.3V supply, it reboots after a few seconds.

It's fine if I turn down the backlight.

Maybe this is a related thing, or maybe it's a real overcurrent....

Or maybe not, it's good enough like it is, I suppose...

i dont know about all of this. Brian hasnt reported a problem and I havent

had so much as a hickup since connecting that hidden pad to ground. Of course we aren

t using the plls yet. Things might get more interesting then.

So im thinking... maybe it is just what happens when that pad floats.

There was a lot of similar discussion and concern with the BeMicroCV and the BeScope as an extra and separate power for the daughter board was actually required.

So the situation may just be typical to all FPGAs. As long as the power supply can deliver enough, the device should perform. Maybe a glue on heatsink would offer some comfort to the worried. I think I even have one or two that I purchased for the SX-48.

In other words, FPGAs will likely generate a lot of comments about 'why is it so hot?' when you begin to use most of what it can do.

I suspect that best thing to do is to run a 24/7 burn in test with all cogs churning. It really is up to Parallax to try that one.

Do you know how stout your input power supply is? If it's not that capable of delivering current, it's output voltage could be getting sagged down, causing the problem.

Guess I could try a bigger one..

When running the backlight, which seems to be a big current hog, check the voltage on the center pin of the power jack from its back side. See if it's sagging. You might just need a higher current wall pack.

Not sure about the P123-A9 power req, but the somewhat similar BeMicroCVA9 has provided a 5V, 3 amp power supply, and more might be required in some configurations. That may NOT be a good comparison as the BeMicroCVA9 has added DDR3 memory and different capacities.

There seems to be a raging debate about what glue is proper for gluing these heat sink devices in place, with a commercial silver powder based glue proving superior thermal conductivity. Arctic Silver 5 claims to be superior to all (I have no way of verifying, but their presentation is compelling.) http://www.arcticsilver.com/as5.htm

Also, the epoxy IC case is a thermal insulator. So actually gluing the heat sink to the underside of the circuit board may provide better cooling that gluing the heat sink to the top of the device.

http://www.element14.com/community/groups/panasonicindustria/blog/2014/11/21/solving-thermal-management-challenges-in-a-minimum-space

My board has been running for 48 hours with 11 cogs running and the cyclome V chip isn't hot at all.

Rayman provided FLIR photos, but no indication of how to gage if the heat is excessive or incidental. It would have been nice to have a surface temperature reading along with the FLIR images.

I wonder if those pyrolitic sheets are intended to divert heat away from circuit board hot spots, lithium cell hot spots, or both. We may never know.

Soldered a 100k 0605 resistor on top of another resistor and now it's all better

Can even run LCD backlight on full.

Here's a photo of the new resistor (with red circle around it):

Which is changing what, exactly ?