Best way to sense a moving noodle?

Hello,

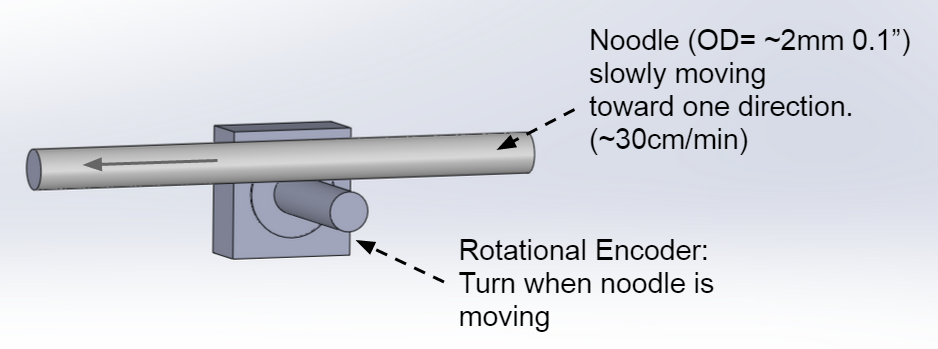

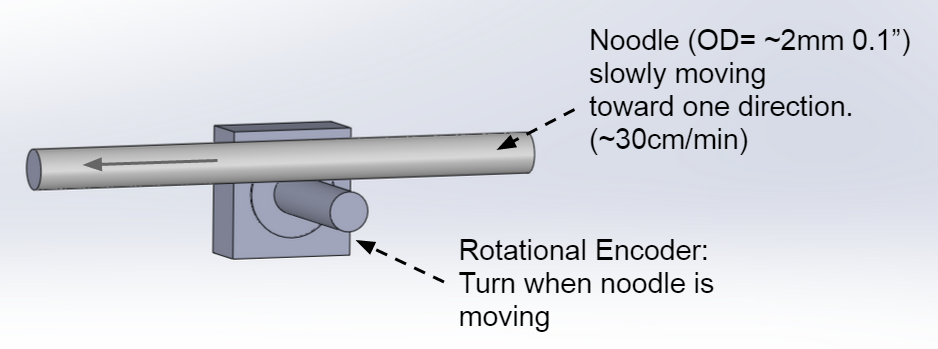

I am working on a project that needs to sense if a noodle is being pulled through or not. Currently I am thinking about getting a ATTiny85 board with a rotary encoder like this (http://www.hobbytronics.co.uk/image/cache/data/sparkfun/com_09117_rotary_encoder-500x500.jpg) that the shaft is butted up to the noodle. My idea is to push the noodle against the shaft. When the noodle is being pulled away, it will turn the shaft. I will just see if the shaft is turning or not to see if the noodle is moving or not.

A couple of questions hoping to get answered:

Is the encoder 'smooth' like those you can find on amplifiers? In other words, no clicking. Best if there is no damping so the encoder can be turned easily on contact with the noodle. What key word should I be looking for?

are there any other good and cheap way to do the same job? Best if the package can stay extremely small. I don't need fine resolution and a rotary encoder has everything (encoder, pin-out, shaft that the noodle can roll on)

thought about using those old mouse optical encoders. But they are kind of big (smallese wheel diameter is about 22mm). Would any one recommend to use the optical mouse sensor instead?

I am working on a project that needs to sense if a noodle is being pulled through or not. Currently I am thinking about getting a ATTiny85 board with a rotary encoder like this (http://www.hobbytronics.co.uk/image/cache/data/sparkfun/com_09117_rotary_encoder-500x500.jpg) that the shaft is butted up to the noodle. My idea is to push the noodle against the shaft. When the noodle is being pulled away, it will turn the shaft. I will just see if the shaft is turning or not to see if the noodle is moving or not.

A couple of questions hoping to get answered:

Is the encoder 'smooth' like those you can find on amplifiers? In other words, no clicking. Best if there is no damping so the encoder can be turned easily on contact with the noodle. What key word should I be looking for?

are there any other good and cheap way to do the same job? Best if the package can stay extremely small. I don't need fine resolution and a rotary encoder has everything (encoder, pin-out, shaft that the noodle can roll on)

thought about using those old mouse optical encoders. But they are kind of big (smallese wheel diameter is about 22mm). Would any one recommend to use the optical mouse sensor instead?

Comments

If you want a very small assembly you could use a surface mount led and photodetector on a pcb that could be less than 5x5mm and use the eye of a large sewing needle to produce the signal as it rotates.

What is the tensile strength of your noodle? I imagine that most noodles are quite weak and fragile, so any drag might break one being pulled through a measuring encoder. Being also soft, I don't quite grasp how one use some sort of other drive to hold on to the noodle and push.

What are the elastic properties of your noodle? Some noodles are very elastic, others are not. IN fact, the Chinese have created noodles of extreme elasticity by adding an alkaline solution to their receipe for 'La mein'

https://www.youtube.com/watch?v=Q6YvVgU9ms8

You are going to have to exert a lot of quality control and material analysis on your noodles before you will likely get any reliable readings.

-Phil

If you're talking about real noodles, you also have food safety issues to consider, especially if the noodle contacts anything.

The noodle is very much like those thick around pasta noodles and does not break easily

Is there a standard naming on the properties of rotary encoders so its easier to find what I need?

I guess using optical encoder and laser cut out the encoder wheel might work as well.

-Phil

The encoder you linked has a "detent" which causes a clicking sound and feel. IMO, it would not work well in this application.

Where is the information about the noodle moving or not going? If it ends up in a PC, then the optical mouse solution could be used directly with the PC. If the output from the sensor needs to be microcontroller friendly, you'll want to find a PS2 optical mouse or some other optical mouse which has been modified to make it easier to use with a microcontroller.

When people asked about the noodling being used for food or not, I think the concern was if the sensor needs to be food safe or not.

If the sensor needs to be food safe, then it sure seems like an optical solution would be easier to keep clean.

Rotational Torque: 50gf.cm max.

Rotational Life 30,000 revolutions

At 1 revolution/second = 8.3 hour life

With the A B C pins producing the 2 phase output this part seems to be a mechanical switch and so would naturally have wear.

An LED-optical will last much longer; perhaps there are LED based encoders out there. The scroll wheel in my Logitech mouse has a slotted wheel with an LED to detect the wheel turning.

If you want small and an optical mouse you might need to remove the optical section and mount it. Perhaps in a stainless steel box with a small window to keep it from getting gummed up.

A google search on "optical mouse movement sensor" got quite a few interesting hits.

If you want a simple "Yes/No", a friction paddle with the opposite end connected to a detector (hall or photo sensor) might work. The size of the paddle would determine the friction.

http://blog.jgc.org/2012/09/conversion-of-cheap-optical-mouse-to.html