crash and fix, vibration

Tracy Allen

Posts: 6,667

Tracy Allen

Posts: 6,667

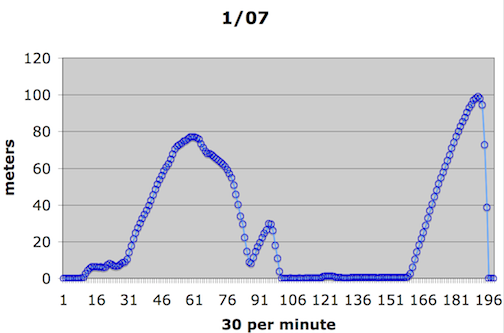

Yesterday a spectacular crash from 100m. It covered the last 40 meters in less than 2 seconds, so over 45mph at impact. The problem was most likely a cold solder joint on a battery power connector, shaken to the failure point by vibration.

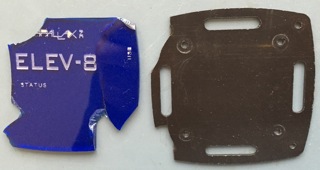

Landed upside down. We had a data logger strapped on top. Shattered the top plates. Also froze one motor, broke rotors.

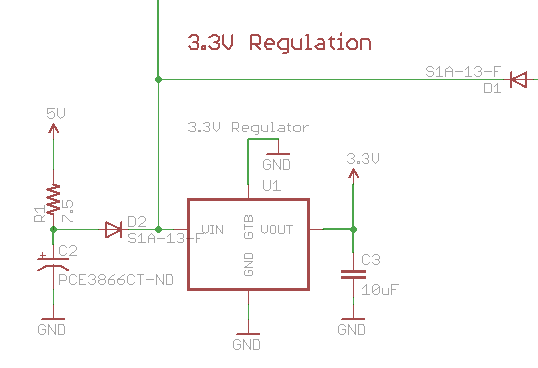

Crushed the power filter capacitor C2 which then took out resistor R1. It took a while to figure that out.

Replaced R1 and C2 with parts on hand. It works!

Built new top plates from scraps of FR4. Should be pretty tough.

Schematic showing C2 and R1.

Replaced motor and props, resync, balance. Still seems to pull to one side at takeoff.

Landed upside down. We had a data logger strapped on top. Shattered the top plates. Also froze one motor, broke rotors.

Crushed the power filter capacitor C2 which then took out resistor R1. It took a while to figure that out.

Replaced R1 and C2 with parts on hand. It works!

Built new top plates from scraps of FR4. Should be pretty tough.

Schematic showing C2 and R1.

Replaced motor and props, resync, balance. Still seems to pull to one side at takeoff.

Comments

:frown:

BTW - what are you using for an altimeter or distance-to-ground?

-Russ

One problem we still have to resolve is vibration. The air sensor has excessive noise in the readings so long as the copter is in the air. We've eliminated turbulence and electrical noise as possible cause.

I'm wondering if the top is the best place to mount it and how to deal with the vibes. What do you guys who use cameras suggest? I know the high end photography is stabilized with a gyroscope gimble mount, and the camera is mounted on the bottom. The controller on the elev-8 with its gyro is mounted in a minimal set of shock mounts.

Russ, the altimeter is an MS5803, which is like the Parallax #29124/MS5607. Code compatible, using Phil's object. It is mounted inside the air monitor with a Prop for data logging to SD card.

Team members, on a good flight day...

I't might be irrelevant because you are a certain altitude where the sample might be consistent.

I have been taking some pictures, but I am not finished the assemble yet.

Will post when finished.

I was thinking about adding extra standoffs above the top plate and holding the device on a rubber slingy thingy.

I was looking at putting rubber washers on to of the top saddle mounts, just below the top main plate. That may isolate the booms from the plate somewhat, but looking again at it now, the 4-40 screws are going to transmit the vibrations right up to the top from the boom. Total isolation is needed.

I think the best bet is to isolate the control board as you decribed.

Jim

The only thing I've got Loctite on is the motor shaft setscrews. I usually check everything else every couple of flights. Seems like it takes a while for things to bed in after any disassembly, but they generally stay tight after that.

Are you balancing the props? Before I mounted a small camera (Flycam One), I was mounting my Canon point and shoot. The vibrations were terrible and so I thought I would balance the props.

Had a heck of time trying to balance the stock propeller hubs (90 degrees to the blades). Ended up drilling and tapping the hubs and adding a screw. Like this:

Probably not a good idea to modify the hub area, but I didn't have an issue. Here's the prop in a balancer:

I eventually broke those props due to "normal" crashes... :-) Haven't taken a lot of time balancing props lately and have made no hub modifications. I generally just balance the blades by adding a piece of electrical tape to the underside. Can't say whether it makes a noticeable difference or not.

I have a set of carbon fiber props sitting in a box. I thought these might be a little stiffer and create less vibration from blade flutter, but haven't tried them yet.

The point-and-shoot images improved, but not enough to be useable. The biggest issue (I think) is that the natural frequency of that mounting was just too low. The mounting point I used was the 1/4-20 connection at the bottom of the camera. I suppose it was a little like an inverted pendulum.

The Flycam is very low mass with the mounting close to that mass - the camera head is separate from the rest of the device. Same copter vibes, but much, much, less effect on the image. Rigid mounting of a support structure with isolation at the device may be better than loosey-goosey mounting of a larger mass.

-Russ

We did some quick and dirty experiments yesterday. First, made a vibration table out of a speaker by gluing a lightweight post and table to the cone. Then tested the sensitivity of the sensor module itself to vibration (Sharp GP2Y1010). It turned out to be strongly affected by vibes in the range of 35–200Hz above a certain amplitude not yet determined. Also tried a variety of isolation media, air bags, rubber bands, steel wool, glass wool, foam pads. The hope being that the mass of the sensor on top of a squishy spring will damp out the motion above some cutoff frequency. That did have a good result, not perfect, but a great improvement. When the sensor is mounted in its enclosure with the support circuits and its own LiPo it weighs 4oz, 114 grams. Second phase super quick and dirty, we put a bronze wool pad between the top of the elev-8 and the sensor assembly, and flew it around the parking lot. So far, the result is encouraging, the signal not so much affected. The means of attachment needs improvement, to isolate the ties to the copter from the ties to the device. This one had an XBee pro digimesh added for telemetry.

Not quite understanding this. Did you use the screw to balance the hub/prop assembly off of the motor? The screw looks likes a lot off mass for balancing.

Jim

A couple of years ago a researcher with the USDA Forest Service fire research lab sent up an earlier version of the particulate monitor over a controlled burn. He had initially suspended it on a rather long tether from the bottom of a Mikrocopter 8. I don't know how long was "long". He told us that it swinging back and forth created serious issues with flight stability, and he ended up mounting the particulate and CO sensors on top. A suitably short tether shouldn't cause that kind of instability, should it?

Yes, it is a lot of mass, but was what was needed to balance the "hub". Yes, I was balancing the prop off of the motor. I think the terminology and the idea of balancing the blades and the hub independently comes from the fact that you can't place a weight at any angular location, since there are only blades in two narrow areas.

So, the blades were balanced with them horizontal, using tape as described earlier. If the prop would remain stationary at either horizontal position (180 degrees from one another), then I would consider the blades balanced.

Then to balance the hub, the prop would be oriented with with blades vertical. If the prop would remain stationary at either vertical position (180 degrees from one another), then I would consider the hub balanced.

If the blades and the hub are balanced, then the prop should remain stationary at any position.

-Russ

What about using 4 lines, one from each foot, in an inverted pyramid formation? That should stop most of the swinging. I tried it out with a drill bit box and some string, and it seemed to work pretty well. Relative to the attached image, the front back motion was very stable. The left right motion got a little bit of a rocking horse situation, though. I'm not sure how much that would affect a quadrotor.