HB25 wire gauge recomendation

Hi,

1) What's the the connector/terminal name used to connect (motor, power wires) in the HB 25 ? Do you know where i can find them ? I've tried Home Depot with no luck,

probably a car/body shop ?

2) What's the recommended wire gauge to connect power to the HB 25, and the batteries to the arlo power box ? Currently i have 2 x 12V 9Amp batteries (PS-1290)

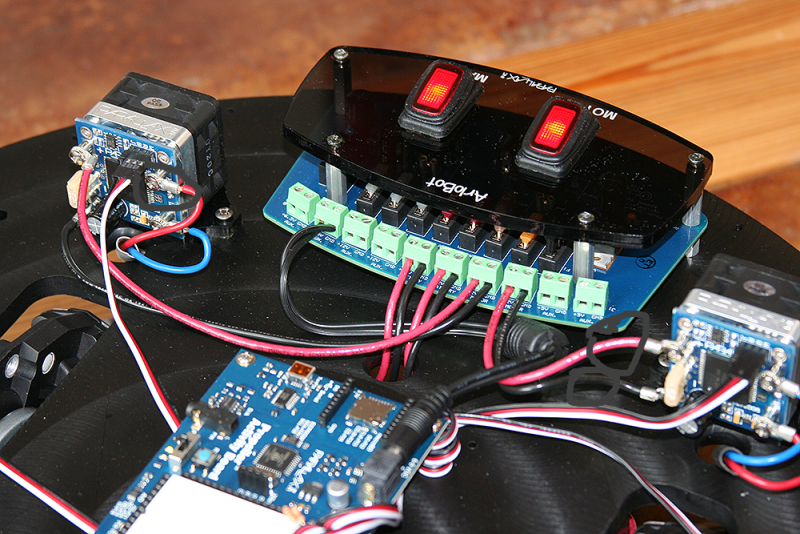

I've upload a picture to help.

Thank you,

Tiago

PS: Happy Holidays :-)

1) What's the the connector/terminal name used to connect (motor, power wires) in the HB 25 ? Do you know where i can find them ? I've tried Home Depot with no luck,

probably a car/body shop ?

2) What's the recommended wire gauge to connect power to the HB 25, and the batteries to the arlo power box ? Currently i have 2 x 12V 9Amp batteries (PS-1290)

I've upload a picture to help.

Thank you,

Tiago

PS: Happy Holidays :-)

Comments

9 amps should be easily handled by 16 to 18 gauge wire. You may want larger wire for start from stall ampacity. I can't seem to locate a chart for less that 15 amps.

http://www.cerrowire.com/ampacity-charts

Oh, here is one for smaller wire

http://wiki.xtronics.com/index.php/Wire-Gauge_Ampacity

Welcome to the forums! Happy Holidays to you!

1)

If you are talking about the green connectors, they are called terminal blocks. Here are some at mouser, (many different varieties):

http://www.mouser.com/Phoenix-Contact/Connectors/Terminal-Blocks/Fixed-Terminal-Blocks/_/N-7rqd7?P=1z1413eZ1z0x3z9Z1z0wxojZ1yx0y8x

and they can be had at Radio Shack, (only one version):

http://www.radioshack.com/2-position-pc-board-terminals/2761388.html#q=terminal&start=1

2)

Check this thread:

http://forums.parallax.com/showthread.php/157636-HB25-Wire-Gauge

Thanks for the feedback.

Regarding the connectors, is not the green ones is the terminal attached to the wire when you connect the power or the motor output in the HB25. It seems stupid simple

EUREKA!

Thanks to point out to the other thread. I think is this: http://www.harborfreight.com/520-piece-terminal-set-67686.html although is a set, i think the specific one is called Ring terminal to fit a 4-40 screw ...

I have both batteries wired in parallel 18 Amp, it seems there are different interpretations, if is to thick (low gauge) i bet will be difficult to use a ring terminal with the HB25,

Still looking ... for the best fit/safest

Tiago

You can run two wires of smaller gauge in parallel to fit the ring connectors. You may need a longer screw on the HB-25 side.

In general, when one desires more power out of a motor, you go up in voltage so that the wires to the motor are kept reasonably small. It is not uncommon to see 24VDC, 30VDC, and 36VDC motors.

Also, the wire size should be based on what the motor needs, NOT the AmpHour rating of the battery cell.

If you stall a motor or jam it to a full stop, the current can soar far above the AmpHour rating. I believe the HB25 has thermal shut-down in such situations to prevent the wire from just burning up. But right sized fusing is also important to preventing damage.

How to figure power to the motor. Well 745 watts equals 1 horsepower. Amps x Volt = Watts. If you have a 1/3 hp motor, you would need to wire for at least 250 watts of power. At 24VDC, that would require 10.5 amps. At 12VDC, that would require a huge 21 amps. But at 36VDC, the less than 7amps would allow smaller wire.

Since the HB25 is only good up to 16VDC, it really should be used only with a 12VDC supply (which is really 13.5VDC full charge, and can go to 14.4VDC on a charger). The 35 amp rating makes it rugged, when temporary loads occur. You are never going to use it with 35 amp steady load at 12VDC.

If you do want more power, go up in voltage as well. Don't try to keep your motor powered by low DC voltage as the higher amps will create more problems with your construction details.

Good Points, special the point low voltages high amps = more troubles.

I end up with a 16 gauge wire, short distance < 1ft

I had to buy about 25 feet of hefty pure copper arc welding cable to go from the battery box to the starter motor solenoid and a ground to the engine block. That's why cars in the 1950s switched from 6 volt to 12 volt systems. 12 volts just delivered more power to the starter motor with less copper.

Yep, and that,s why a lot of the big diesel trucks use 24V for starting.