Motor Mount & Wheel Kit Maintenance, Which Grease?

Duane Degn

Posts: 10,588

Duane Degn

Posts: 10,588

Ken set me a set of Motor Mount & Wheel Kit - Aluminum so I could test Eddie firmware using HB-25 motor controllers. More information about this project can be found in the Open Propeller Project #8 thread.

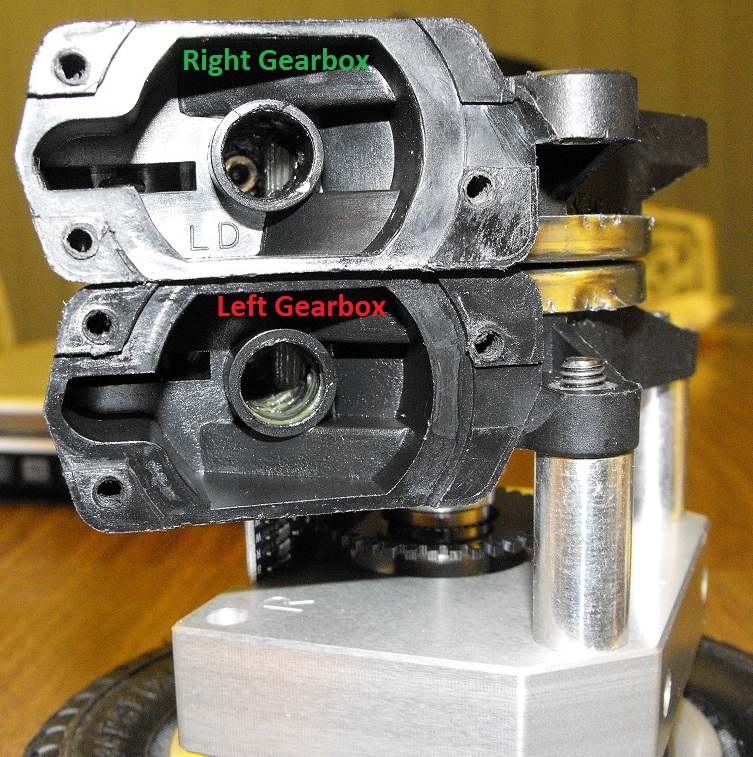

When running without a load and at full speed the left motor on my robot draws about 1 Amp at 12V. The right motor was pulling more than twice this amount in the same conditions. I decided to check how well my gift horse was flossing and found the right gearbox didn't contain nearly as much grease as the left gearbox.

Here's a picture of the wormdrives pulled from the gearboxes.

The gearboxes have a crimped lid. I was really tempted to pry one off but I'm sure the metal can only be crimped in place a limited number of times.

Here's a picture of an attempt to look inside the gearbox from the wormdrive's opening.

I scooped up about half of the grease from the left wormdrive and applied it to the right wormdrive. The right motor and gearbox now draw about 1.5 Amps instead of over 2 Amps but I'd really like to add some additional grease to both gearboxes.

I understand it's important not to mix the types of greases used in a mechanism. Other than knowing this grease is tan in color, I don't know much about it.

I was hoping to order some grease from Amazon or other online dealer. Do any of you have any suggestions on what type of grease to get?

When running without a load and at full speed the left motor on my robot draws about 1 Amp at 12V. The right motor was pulling more than twice this amount in the same conditions. I decided to check how well my gift horse was flossing and found the right gearbox didn't contain nearly as much grease as the left gearbox.

Here's a picture of the wormdrives pulled from the gearboxes.

The gearboxes have a crimped lid. I was really tempted to pry one off but I'm sure the metal can only be crimped in place a limited number of times.

Here's a picture of an attempt to look inside the gearbox from the wormdrive's opening.

I scooped up about half of the grease from the left wormdrive and applied it to the right wormdrive. The right motor and gearbox now draw about 1.5 Amps instead of over 2 Amps but I'd really like to add some additional grease to both gearboxes.

I understand it's important not to mix the types of greases used in a mechanism. Other than knowing this grease is tan in color, I don't know much about it.

I was hoping to order some grease from Amazon or other online dealer. Do any of you have any suggestions on what type of grease to get?

Comments

Your local Auto Parts store should have good selection of grease to choose from. A general purpose grease should work. An automotive wheel bearing grease would be too thick. This link maybe useful to look at http://www.etrailer.com/faq-grease.aspx

Tony

Thanks for the link. There's a lot of useful information there. One thing which concerns me is:

The gearbox on these don't make it easy to clean out the old grease. If I don't get a reply about the grease type here in the forum, I'll email technical support and see if they know.

You can get smaller tubes of it at places like Harbor Freight, Home Depot, and so on. Example:

http://www.harborfreight.com/automotive-motorcycle/lubrication/85-gram-super-lube-grease-cartridge-93744.html

Just to overstate the obvious, things to NOT use: WD-40, machine oil, mayonnaise.

I think you'll be find if you get out as much of the old grease as you can. The little bit that's left isn't going to hurt an application like this. This is a fairly light duty.

That looks like the same stuff I was wondering about.

Vaseline is still on the good list? (not)

Good to know. Thanks for the advice Gordon.

Edit: Throwback Monday to my favorite (spur)gearmotor which is quite torquey, idles at 100 mA or less and stalls at 500 mA on 12V! http://forums.parallax.com/showthread.php/117280-Nice-10-Gearmotor

Those are getting hard to find now, glad I hoarded some!

BTW any auto store will have solvents for removing grease.

Does the motor have the same no-load current in each direction? Also, it would make a difference if the no load speed was greater on one than the other.

Well, that and cheap for the gearing ratio you get.

Everyone should really be using power chair motors -- they've got great gear ratios, are much more efficient, and unlike motors originally intended for power windows and such, are designed for continuous use. I just wish some Chinese factory would start churning them out for $25 pop. Will that ever happen?

Before combat robots, there was a time surplus power chair motors could be routinely found for under $30. Now NPC wants $400+ for a new one. Yikes.

Or this one:

http://www.amazon.com/Electric-Wheelchair-Worm-Gear-Motor/dp/B00PA422LG

which works out to almost a foot per second if you use 2-foot diameter wheels.

Instead of adding more grease is there a way to contain it where it needs to be? It looks like it all wants to creep onto the shaft. If there were an o-ring to keep it contained to just the gear area you probably have more than enough there, maybe even too much.

The main problem worm gear drives suffer from are high friction from the worm (screw) gear sliding across the teeth of the output gear. This produces heat, the heat thins the grease and makes it expand, the expansion forces the grease away from the gear or out of the housing, both of which can create voids around the gears. Those voids result in more friction, more heat, more expansion, more loss of grease on the gears, etc., etc., etc.. The end result is usually a seized gearbox and burned out motor. That's why ball screws are used for high reliability low speed drives.