C3 board repair possible?

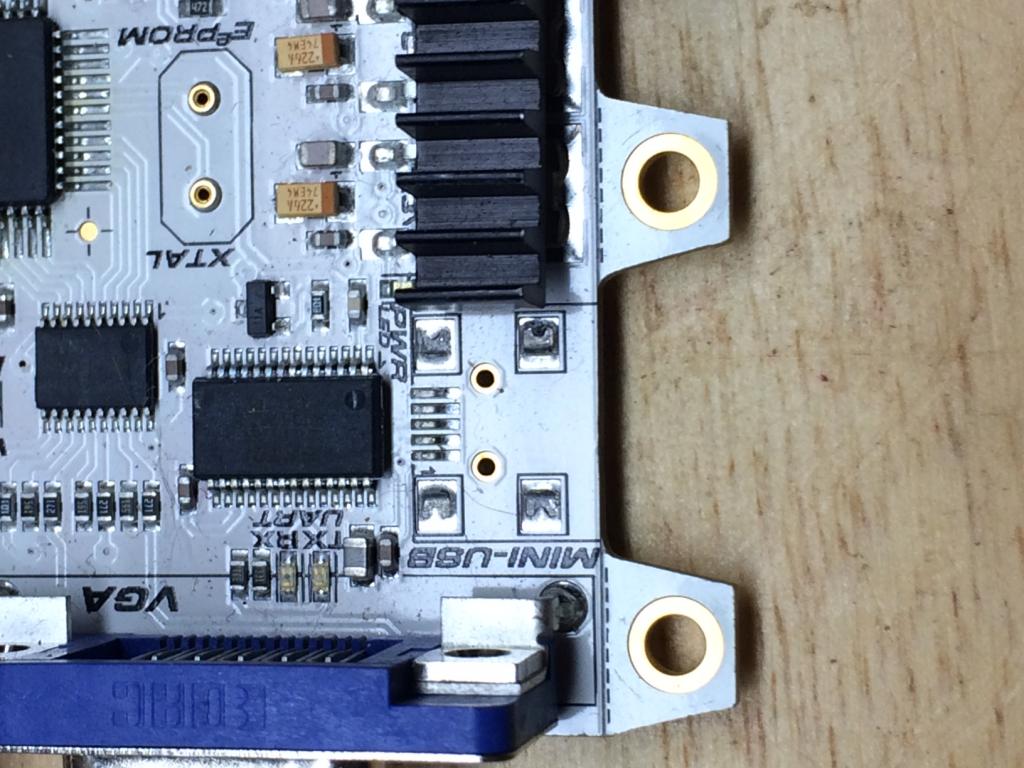

I made a huge mistake by not unplugging the USB cable from my C3 board prior to packing it in a backpack. The mini-USB connector was pried/pulled off the board and I am wondering if anyone has the nerves, eyes and equipment to replace that connector. Please see attached image; I think it's fixable as the board itself does not appear to be damaged and the traces were not pulled up as far as I can tell. I will be more than happy to pay a fair price for this repair. Can anyone help me?

Thanks, Mike R.....

Thanks, Mike R.....

Comments

My knee-jerk reply is that it can be done. However, I'll need to dig out my C3 to evaluate it more closely. The clearances for the other components could pose some difficulty.

I'll look.

Doc

I've replaced enough micro USB connectors on Kindles to be pretty confident I could do this if you have a replacement connector. If you don't have one, I'll look though my stuff to see if I have one but I don't want to look through my connectors if I don't need to.

Mike

Do any of you have other suggestions?

Those look good, but taking another look at my C3. the two ground connections under the heat sink are pretty close.

I have a tip that should do it if you chose not to take on the challenge.

Now to get the connectors. All mine have been used.

Jim

I have some of those exact same USB connectors; extras from another project.

Drop me a PM with mailing addresses and I"l send either/both of you a couple to play with.

Ohio will probably be a bit quicker than China.

I just looked at one of my C3 boards - the ground tabs under the heatsink do look like a good challenge!

@Mike, Have you sent the board?

The heat sink on my C3 is just a hair's width away from touching the USB connector but it looks like the heat sink on Mike's board doesn't over hang the USB solder pads like it does on my board.

Here's the photo Mike posted.

It's tight but not too bad. I'll be very surprised if I can't fix it.

I just noticed the ebay seller says the parts are shipping from Michigan. Hold off on sending your connectors.

I had ordered these guys from China. It came out top be $5.50 for 20, including the shipping.

Don't think of all of us "virtually" watching you as you solder!

The micro USB connectors weren't too bad. I'm hoping the mini USB isn't much worse.

I still think it's doable with a very small tip.

Cute little practice cards...that serve a dually useful purpose.

Good Luck.

I had done this a while back at home with an air pencil fashioned McGyver style from a Radio Shack repurposed solder sucker and aquarium pump. google and see a couple examples of this device.....

But I plan to use a soldering iron with the USB connector. I've don't want to burn the board with hot air.

The USB connectors from Michigan also arrived today. A couple of the USB connectors weren't damaged (they were sent in an unpadded envelope) and I used one which survived the trip to repair the board.

I thought I had done a good job until I saw the above photo.

The front of the connector looks like I had expected.

I loaned the board a crystal and tested to make sure the board could send data to the terminal window and receive data back from the terminal.

Even though the solder job doesn't look great, it appears to work correctly. The board was powered over USB for the test.

Are there any other tests to perform to make sure the USB connector is working properly?

BTW, I fixed this board before I started populating my new hexapod boards. What demon possessed me that I behaved so well?

Unless any of you have suggestions for further tests, I'll get this back in the mail tomorrow.

...that's real nice of you Duane. :thumb:

Duane, that looks AWESOME! In retrospect I should have printed a return shipping label, my apologies. Please let me know what I owe you and

what your preference of payment is. Paypal, check, bag of pennies, your wish is my command sir.

-Mike

Duane,

Looks like you had a lot of room to work with by the heat sink. Mine heat sink is shifted over about 3/16", making very hard to get a tip in.

Nice work!