PETAL SPINE - flexibility and durability

Hi folks,

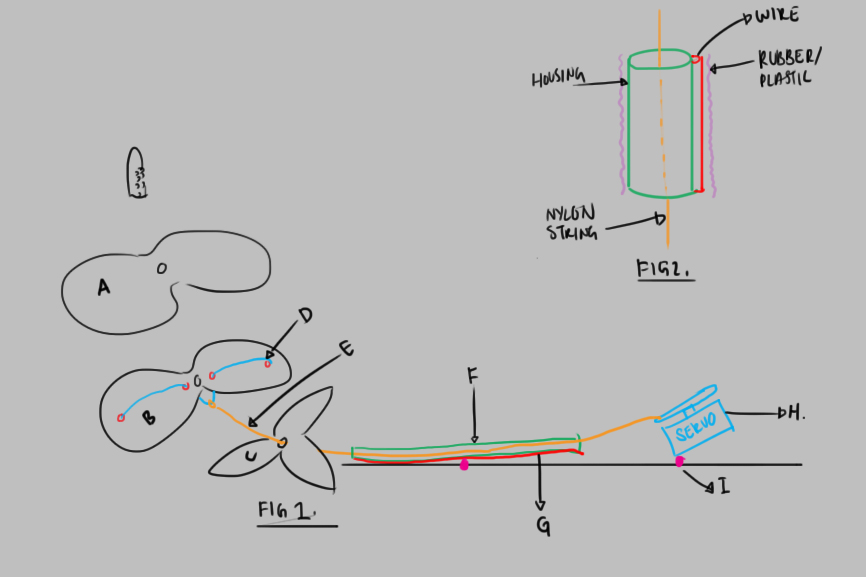

Working on making a mechanical project to make an artificial flower move two of its petals using plastic spine within the petals, fishing wire, Parallax servo and a homework board.

See video: https://vimeo.com/108456552

ISSUE: the tiny (2-3cm) plastic spine (within the petals that makes it move) doesn't retract back to the original position after extensive use. Muscle memory not happening.

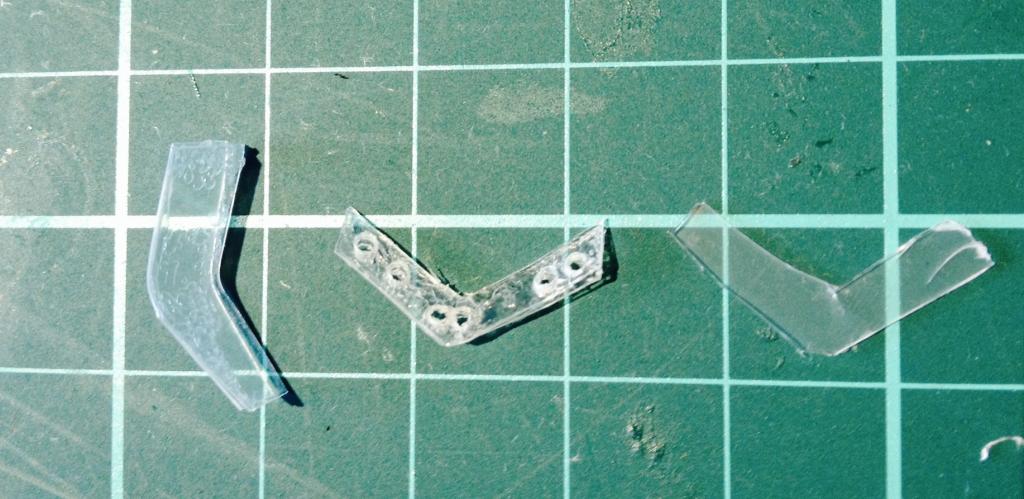

MATERIAL: I've tried tuperware plastics, folder plastics (see attached pics).

HELP! What kind of material is flexible enough in this 2-3cm size and retractable? Pls see the video.

Thanks!

Working on making a mechanical project to make an artificial flower move two of its petals using plastic spine within the petals, fishing wire, Parallax servo and a homework board.

See video: https://vimeo.com/108456552

ISSUE: the tiny (2-3cm) plastic spine (within the petals that makes it move) doesn't retract back to the original position after extensive use. Muscle memory not happening.

MATERIAL: I've tried tuperware plastics, folder plastics (see attached pics).

HELP! What kind of material is flexible enough in this 2-3cm size and retractable? Pls see the video.

Thanks!

Comments

sandwiching several thin layers together to adjust the stiffness,

possibly looking at how leafsprings work for inspiration.

A really good read on RC type linkages is at:

http://www.bpesolutions.com/bpemanuals/Servo.Info.pdf

HINGES - PETAL SPINE: unfortunately they would be too big as the petals range about 1.5-2cm, and secondly, the hinges would be too stiff...it needs to bend slightly.

PUSH PUSH METHOD: yes, ideally if I could control it opening and closing, but it's a fishing line so pushing would be impossible, no? I've read the full document on RC type linkages and not sure how that would work in this case with fishing line strung up about 10-15cm of copper tubing. But the doc was a real informative read though. I'll start a separate thread on this i think

Tks!

a great pull-only method, so little friction.

I'm currently testing the leaf spring method and fishing line...currently on it's 3rd day and going well. Needs to last 3 months ;p

Tks!