Battery Circuits Which is Better?

Hi

I'm building a small battery power supply.

I need 9Volt circuits and 6Volt circuits.

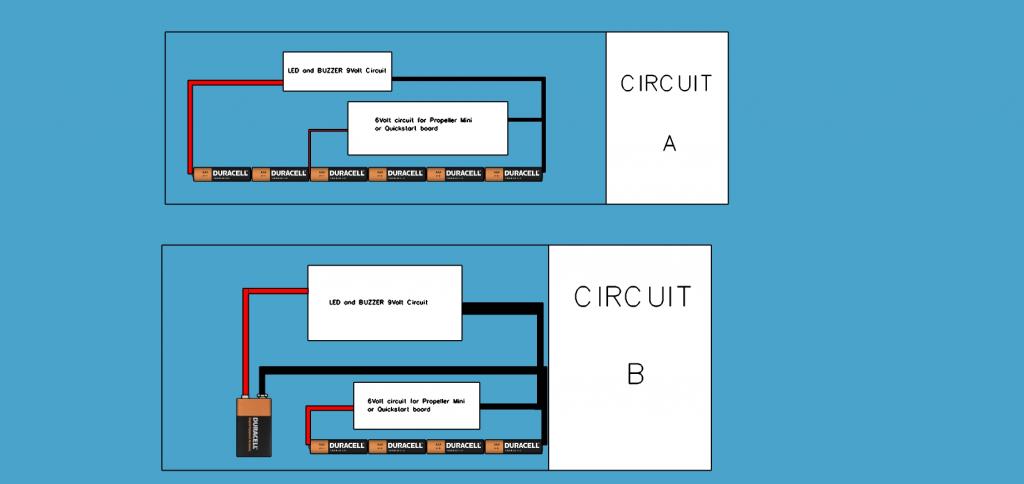

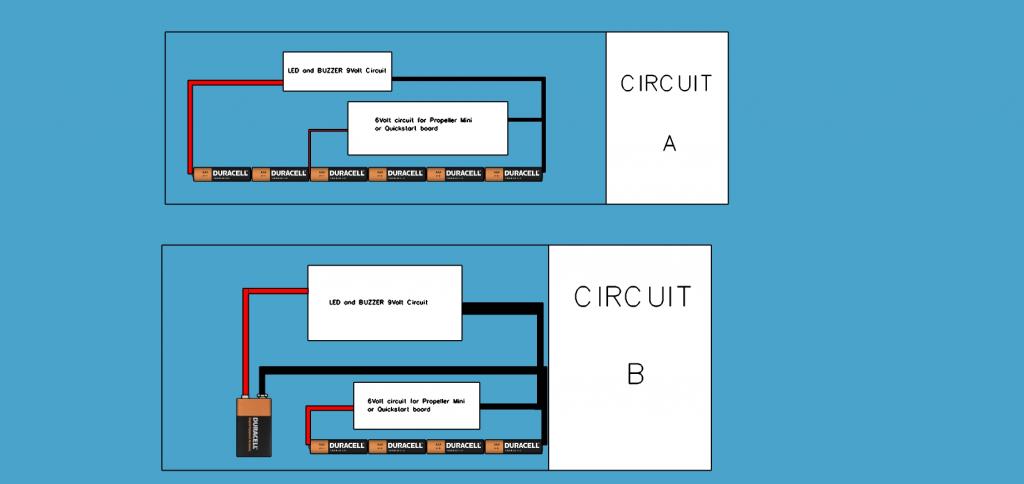

I decided to use one of the two circuits shown in the drawing.

I'm looking for minimum size and weight.

Question is, will I be getting myself in trouble by using either of these?

Circuit A - is tapped AAA battery circuit

Circuit B - is 9Volt battery and AAA batteries.

This should be easily understood by me, but I can never decide between these.

Any suggestions, advice, comments will be appreciated.

I should have said that the 6Volt circuit runs from the time I turn on the Propellers

The 9Volt circuit only flashes LED's and Buzzer every so often.

I'm building a small battery power supply.

I need 9Volt circuits and 6Volt circuits.

I decided to use one of the two circuits shown in the drawing.

I'm looking for minimum size and weight.

Question is, will I be getting myself in trouble by using either of these?

Circuit A - is tapped AAA battery circuit

Circuit B - is 9Volt battery and AAA batteries.

This should be easily understood by me, but I can never decide between these.

Any suggestions, advice, comments will be appreciated.

I should have said that the 6Volt circuit runs from the time I turn on the Propellers

The 9Volt circuit only flashes LED's and Buzzer every so often.

Comments

To verify quickly just measure the current draw of your circuits. Why do you need 9V for the LEDs, 5V is enough for most even blue ones?

And there are buzzers that work at 5-6V too

The capacity of AAA batteries is about double that of the 9V,

starts to not be as bright as I think it should be.

I more than likely should have done research on the type of LED's to use, but I started my project on a Whim.

Radio Shack had good price on some LED strips, I decided to use those for this project.

Also, the Buzzers would more than likely work on my 6Volt supply, but they appear to have more volume at 9 Volts.

My main concern has to do with the fact that my Propeller mini board and RC receiver draw 25ma continuously

whenever I have it turned on. (I didn't mention the RC receiver in my question).

The continuous minimum current draw on my Prop and RC receiver is about 25ma

This will wear down my AAA batteries pretty quickly - I'm thinking about 40hrs operating time.

The 9V circuit, more than likely will only operate about 5 minutes per hour or less.

What I'm wondering about the two styles of circuits is:

Am I better off using the 6AAA batteries under the condition I just described or

will I be better off using the 9V battery for short term 9V and using the 4AAA batteries for running the Prop/Reciever circuit.

I'm designing 2 housings to hold the batteries.

I want Lowest possible cubic inches for the cases of either configuration.

I understand that a current load for items wired in series draws same current.

What happens when you have 6 batteries wired in series and you tap the batteries at the 6Volt point

and occasionally turn on the 9Volt circuits.

Thanks for your comments and suggestions so far

All comments and suggestions are very welcome.

Garyg

And using 9V cells or AAA alkaline cells may be the easiest to get commercial, but they are not rechargeable.

Dual voltage power supplies can be done in other ways. I am thinking that your high DC voltage can be an unregulated 7.2DC and the low voltage is requires regulation.

These days, there are a lot of very inexpensive DC-to-DC up-converters or down-converts. So it might be better to start with something like a 7.2 Lithium ion battery pack to provide your 7 volts, and one energy-efficient down-converter to provide your lower voltage.

The lithium cells to provide more power for the size package than the Alkaline cells, and are quickly rechargeable.

++++++++++

I suspect that neither of your two schematics will really satisfy you over the long-haul.

drain at the same rate (tapped battery arrangements aren't a good idea as cells can be reverse driven due to unequal

discharge rates).

There are cheapish plug-in replacements for the 78xx range of regulators that supply 0.5A or 1A and which are little DC-DC

converters. But if you are powering a Prop you'd want a 3.3V rail surely? Why 6V? Why 9V?

If I allow the voltage to go below 7Volts or so, I lose the Brightness that I like.

The 6Volt part of the supply is being used to power the Propeller Mini board and a small RC remote receiver.

I tested the RC Receiver and confirmed that for my purpose it will also run on 3.3V for which I am taking from the Propeller Mini 3.3V.

My thinking here is that I can use the regulator on the Propeller Mini to get the required 3.3V

6Volts was chosen because I'm thinking that it will give me some headroom so that as the 6Volt batteries

are draining, the system will operate for a longer period of time.

I had a feeling that the tapped battery circuit would not be a good idea.

Mark_T's explanation makes sense.

Though the Propeller Mini board will run at 6.0 volt, it can run at 7.2 volts too, and still provide a 3.3v output. You could run at 7.2 volts by using 6 NiCD rechargeables, but AA cells are really much better than AAA cells for running lights.

I think that the Propeller Mini's low voltage regulator actually consumes more power at 6 volts than at 7.2. volts. These low drop out regulators tend to consume a lot more power when the regulator is in the low drop out region. I would really have to read some paperwork to confirm this, but it is very likely that 6 volts is wasting more power.

Two 14500 Lithium Ion cells are a wee bit longer than AA cells and would work.

The AA battery holder is a very tight fit. You would need a charger for them. And you have to be very careful to not let them discharge below 3.3 volts.

I actually like two 16340 Lithium ion cells better. They fit nicely end to end in a 16550 battery holder that is easy to buy.

http://www.batteryjunction.com/rcr123a.html

http://www.batteryjunction.com/14500-category.html

I'll check out the 16340 Lithium ion cells you suggested this evening.

Those cells may actually fit into a smaller package than my AAA and 9V battery arrangement.

I spent some time after following the links you posted concerning

the 16340 and14500 lithium batteries.

I attempted to find information about 16550 battery holder, but my searches did not yield results.

It looks like the Batteryjunction people will be able to sell me a charger.

I really like the idea of using two 16340 Lithium ion cells.

I suppose I could purchase some battery end connectors and build them into

the housing I'm working on.

Shop around for good prices. BatteryJunciton was just a quick example.

I don't think I will ever buy another 14500 Lithium cell as their extra length is just enough to really need its own special box, but retailers and manufacturers see to thing that the AA boxes will do fine. I won't.

A double CR123 or CR123a battery holder or a single 18650 battery holder (I previously got the number wrong) is what you should get. The 18650 holder will hold two of the 16350 cells end to end.

It is so much easier to shop in a real store for these than to read all the fine print online. Too many numbers and sizes.

If you use one 18650, you get only 3.7VDC.

http://www.amazon.com/s/ref=nb_sb_noss_1?url=search-alias%3Daps&field-keywords=18650+battery+holder&rh=i%3Aaps%2Ck%3A18650+battery+holder

If you buy a charger than can charge 4 cells or 2 cells and is adjustible for 18650 or the smaller 16350, it will likely charge the 14500 too. I have one charger that does all three.

Mostly I use a twin 18650 battery holder and two 18650 cells to run my Propeller projects. But I tried the other smaller cells. I just don't need to go so tiny. You have to recharge a lot more often.

PLEASE... double check that two 16350 cells will properly fit an 18650 case. I make typos and do get confused about the details at times.

If you have an old cell phone, or any cell phone -- you can use that as your battery charger. You just use Lithium cells that fit in the phone and must build a battery holder for two of these flat cells stacked together in the one hole, but one flipped to allow for seperate edge contacts.

You get a free charger, and the flat cellular phone batteries are idea for small projects -- better than fitting round batteries into a square box. And may be cheaper too.

Making a battery holder would require getting a square of plastic (say acrylic) that is about 1/2" larger than the batteries on all four sides, cutting a nice tight rectangle hole to fit in both cells. The thickness would have to be the same as or deeper than the two stacked cells. And then the problem becomes how you configure the contacts to connect the batteries.

I would make shallow slots for the spring steel.

You would maybe position two cells so that the edge contacts are in different locations on the plastic frame. I guess the edge contacts might need to be made out of some bits of spring steel. They can be fitted into a notch in the plastic frame. Make the notch with a file. Metal files work fine on acrylic plastic for detail work and smoothing edges.

After you get all the contacts working right and the batteries held tightly in place, wire them up in series.

++++++++++++++++++

I have an old Nokia that I have saved for this kind of set up. The batteries are always easy to buy. I just have never taken the time to build the battery holder. It would probably take me an afternoon if I got motivated and had the materials ready. Cut the battery hole with a coping saw by hand. Try to find spring steel from old battery holders, or use bits of steel that is used for banding crates.. it is quite springy.

Does that make any sense or do I need to draw a picture?

Then again, if you are confident with your soldering ability... you could just take two fully charged cell phone batteries, tape them together and solder wires on in a series setup. When you need to recharge, you have to unsolder and clean up... everytime.

BE CREATEIVE ABOUT this.

I found something at Jameco

Does this look like it would be a good start?

http://www.jameco.com/webapp/wcs/stores/servlet/ProductDisplay?langId=-1&storeId=10001&catalogId=10001&productId=2144251

They also appear to have the 18650 battery holders.

16.5 mm Diameter x 34 mm length. Two of these would be 68 mm long.

==========================

The 18650 battery is 18.2 mm Diameter x 65.0 mm long, and Jameco seems to have only 2x 18650 battery holders, no 1x.

18.5mm Diameter, 18.5 mm length (2x 35.5mm == 71.0 mm) Seems a bit of a tight fit, but worked for me.

Like I said, it is easier to visit a store and look at what is on the shelves. But I did make a few mistakes along the way, even then.

It could be the 18350 that will work if the battery holder spring allows for extra length. 1200ma at 3.7 volts is excellent.

http://www.batteryjunction.com/ultrafire-18350.html

Or the 16340 is another choice 880 ma at 3.6 volts

17mm diameter, 35mm length (2x = 72mm length)

http://www.batteryjunction.com/uf16340.html

Sorry but there are a lot of these with small variations in size and capacity. But ONE charger can be bought to work with all of them.

https://www.google.com/search?q=16350+battery+dimensions&client=iceweasel-a&rls=org.mozilla:en-US:unofficial&tbm=isch&tbo=u&source=univ&sa=X&ei=tv2qU8HBLM2LkwWc9YHICw&ved=0CGYQ7Ak&biw=1024&bih=382

could be communicated to help you in your plight, if such is an exacting target.

My usage is so simple and basic that I should be able to figure this out -Even By Myself.

However:

Battery Things are very confusing to me.

So far Mark_T and Loopy appear to be guiding me in a direction that I can actually follow.

I really don't know where to find a chemical engineer.

This is really basic stuff that I should have been able to learn from my younger years education.

So far what I've learned is that,

more than likely, tapping into a string of AAA cells is not a very good idea.

Using 9V battery and 4 AAA cells will not be long lived, but It is an option.

The Loopy Byteloose discussions have been the most thought provoking.

Providing 7.2Volts to the entire circuit using the lithium Ion batteries seems like it would

be almost if not absolutely perfect solution to what I'm attempting to do.

I am, however, working on my 4AAA+9V non rechargeable battery box.

This is plan A.

The Lithium battery solution is very much better than my 4AAA+9V So:

I will keep trying to locate sources that I can use to develop the Loopy solution.

I live in small town Wisconsin, Actual stores that sell anything beyond standard anything are unknown to me.

My local choices for real brick and morter stores are.

Radio Shack

Menards

Home Depot

There are several Electrical Supply houses, but they really don't do anything with hobby electronics at all.

About 10 years ago, all of the Electronic repair shops ie.Tv Repair shops closed their doors.

I should be able to use Internet sources like Digi-Key, Mouser, Jameco.

but my searching skills at filtering etc. on those sites definitely leaves something to be desired.

REALLY:

I'm not being negative here.

I keep trying.

Things that cause me great difficulty in building anything electronics area related are:

Non Standard batteries and holders

Small flexible cable - 20ga or so

Small connectors

Header strips

Plug in connectors for such small Header strips

This should be simple.

I'm sure I'm not the only person in the world that needs to make do with whatever I can find or cobble together.

I got a bit long winded here

Sorry if my ramblings wasted your time.

Thanks for every comment, suggestion, words of wisdom.

Garyg

I was just trying to avoid a boost regulator and shift over to Lithium ion for more capacity.... plus have a chargeable solution.

The problems with my solution is that you do have to deal with 3 elements -- charger, battery, and battery holder. This all depends on whether you want to invest in all this or not. But you can skip the battery holder problems by creating a dummy battery that fits into the charger and provides a cable plug in. Then you can solder a cable permanently to each rechargible cell. No problems of a good fit on a battery holder. You can even do this with flat lithium ion cell phone batteries.

As usual, there is more than one way to solve the problem. And so much depends on both your goals and available resources.

++++++++++++++

But some math might be useful.

I don't think you need to go as far as seeking out a chemical engineer. Amps x Volts = Watts, and so...... AMP-Hours x Volts = Watt hours. 1000 mAmp-hours equal 1 Amp-Hour.

If you have a 6 volt battery with 1200 mAH or a 7.2 volt battery with 800 maH, you should be able to figure out which is the most capacity in Watt-Hours

6x1.2= 7.2 watt-hours, while

7.2x 0.8= 5.76 watt-hours

Inserting a converter will create a loss.... something like 15-20%

So if you use the 6 volt solution with the AA or AAA cells, you may l have to adjust your watt-hours delivered. 7.2 x .85 = 5.76 (Argh... the same outcome)

It is up to you how you want to do it. You can either invest in step-up regulators and step-down regulators or you can invest in rechargeable batteries and a charger. (Sooner or later you will probably all of these.)

++++++++++++

But I do suspect you can use cellular phone batteries to get more power in tiny flat packages. And with a dummy battery build to provide a plug in cable for recharging, you wouldn't need a battery holder. Just solder cables to your lithium cells that mate with the plug in. I suspect you can find an old cellular phone or cell phone battery charger for free. So the cost would go down, and you would get a big win on having the small size you desire.

I'll be using all of the information you guys provided as I continue to develop

a convenient, small, battery power supply case.

This is really not quite as straight forward and simple as I originally thought.

Since I really need to get started on something physical that I can hold in my hand

and say, Hmmm maybe I'll need to do this next time.

The attached photo is a drawing of the box I have started building.

I completed the circuit board holding the switch and piezo buzzer.

I made forms so that I can glue up a Plywood box, 1/16" thick.

While I'm really not satisfied with the finished size, I'm thinking it will feel like

a brick in my pocket, This will give me the ability to find out if my overall project

will work out in the end.

Thanks for all of your support so far.

Garyg

And just use one of these >>>>>>http://www.ebay.com/itm/2600mAh-USB-Power-Bank-Portable-External-Battery-Charger-for-cell-phones-and-mor-/121369917868?pt=US_Cell_Phone_PDA_Chargers&hash=item1c4235f9ac

You use the USB port on your computer to charge the power pack.

a pretty good solution for my situation.

I started looking for USB female connectors, found some at Mouser.

I've heard that USB cable wires are difficult to splice, meaning USB connector on

one end and bare wires on the other end.

I may just order some USB sockets and see how they would work out.

Thanks

Garyg

The amp capacity of a wire is directly related to the cross section of the copper wire. So thread-like copper wires are not really going to provide much power without adding resistance and voltage drop. You need at least 28 gage wire and larger would never hurt.

So it would be wise to build your own power cable to be assured 1 amp or more. There are power packs that will deliver several amps.

IF the USB power pack comes with a cable, the internal wire might be larger diameter and properly rated for optimal performance. Try to buy with cables included.

Crimp connnects are relatively higher resistance, so solder your power cable connections.

+++++++++++

The main thing here is to get you into a method that doesn't create a lot of clutter with odd batteries and can be transferred to other projects in the future. Also, you wanted tiny, and need about 7.2 volts. So the boost regulator will be a very flexible solution.

I'm still working on this quest for small size battery pack with proper voltage/voltages.

So far, I haven't been able to find a source for the combination of batteries, holders and proper battery charger circuit

that I can use.

Next time I go to Milwaukee, Wi., I'm planning on stopping at one of the electronics places there.

I like the idea of using two 16340 cells in an 18650 holder as a small package solution.

Since my current project started by reading about wearable electronics, I went to the Adafruit site to see what they had to offer.

I found some lithium Polymer flat, 3.7volt 2500 ma/hr batteries in flat pack.

Adafruit also sells a battery charging circuit that would work with these batteries. http://www.adafruit.com/products/328

I finished building my plywood battery box for the AAA+9v batteries that I'm using to test my project.

A drawing of the battery box is in post 18 of this message thread.

I'll attempt to attach my prototype battery holder box and directional LED thing to a vest the my wife will be wearing.

I'm getting closer to completing my mission.

I just thought I would let you know where I'm at with this quest.

Thanks for listening and commenting.

Garyg

I guess the 16350 cells -- which are 3.6V -- will never fit right.

I strongly suggest you just go back to a bank of AAA cells and DC-DC booster board. You can actually use a tiny LM2577 Booster board with just about any small battery pack that is lower than the output. In this way, you can get 7.2 Volts provided to everything.

You could even use ONE 3.7V 16350 cell and boost that to 7.2VDC.

The ADAfruit flat pack would even work nicely with the LM2577 DC-DC converter....

Everything points to that converter solving your size constraints. With a little luck, it may actually just shut down when the Lithium cell gets closer to 3.0v and you won't have to work about monitoring low voltage.

http://www.ebay.com/itm/New-LM2577-DC-DC-Adjustable-Step-up-boost-Power-supply-Converter-Module-/140741642172

But of course, the smaller the battery pack, the less the power regardless of your desires to have otherwise.

Lithium 16350 are likely to be your best form factor for power to size and weight. But you have to buy a recharger and be sure to not let them go below 3.0VDC discharge.

9VDC cells are some of the worst for delivering optimal power in a small package. I use them in my multimeter, my capacitor meter, and some other devices, but they really are not a good choice for new stuff.

Since I have an LM2577 and the 18650 available, I guess I should do some testing to see how well they hold up. The LM2577 says it wants 3.5V or more. And the 18650 may be cut off prematurely with a lot of power left from 3.5V down to 3.0V.

http://www.ebay.com/itm/New-LM2577-DC-DC-Adjustable-Step-up-boost-Power-supply-Converter-Module-/140741642172

The documents don't explain clearly how it behaves below 3.5VDC, but there is mention of a 2.9V under-voltage lockout. Voltage Boost may only be good from 3.5 volts and above.

That seems to indicate that the LM2577 might work well with one Lithium cell to boost voltage AND protect the cell of excessive discharge by an orderly shut down.

I still have to do some testing to see what happens to regulation in the 2.9 to 3.5 volt region -- voltage may drop or the oscillator may just shut down. I have no idea.

There are a lot of 18650 cell discharge graphs on the web and they all pretty much say the same thing.

http://www.candlepowerforums.com/vb/showthread.php?84980-2400mAh-LG-18650-cell-discharge-graph