Wheels that fit the Parallax Unipolar Stepper Motor?

Hi all,

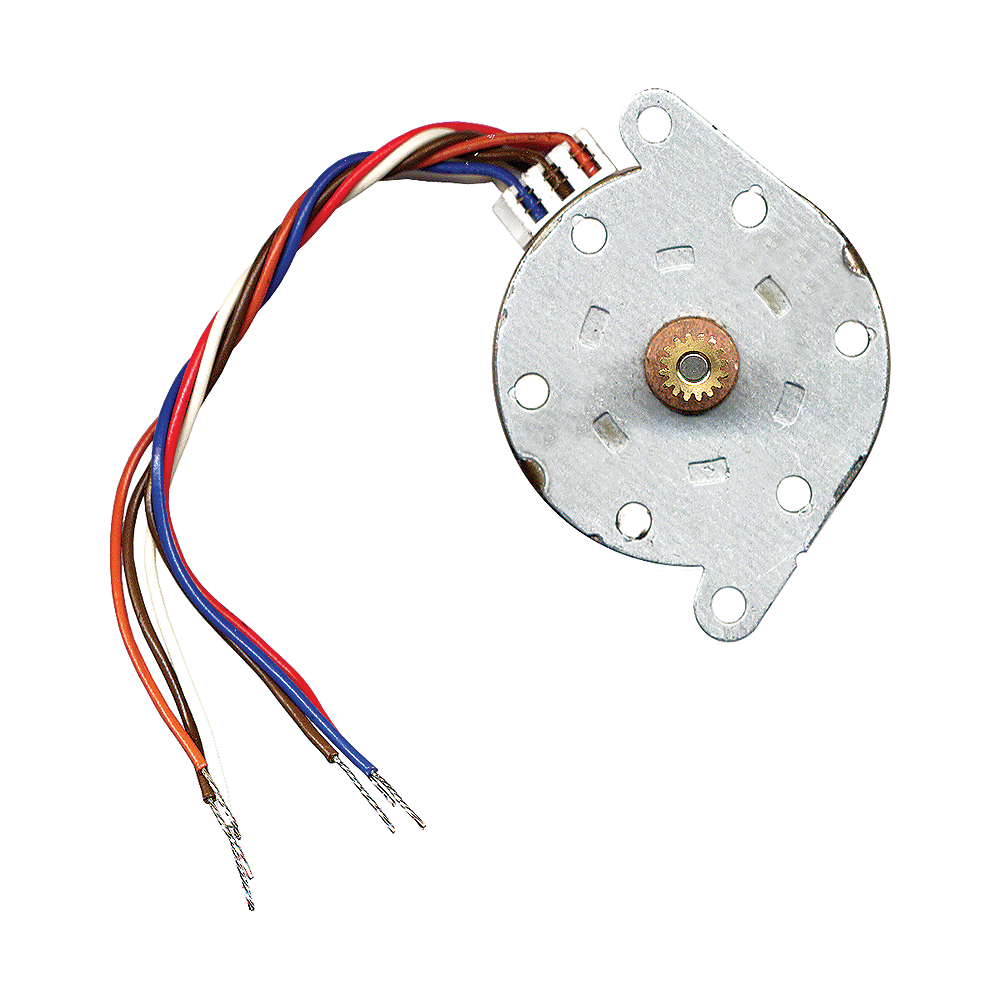

I purchased a pair of Parallax 4-Phase 12 Volt unipolar stepper motors (http://www.parallax.com/product/27964) with the hope to create a small, programmable vehicle. This was actually an exercise in a novice electronics book and the part mentioned in the tutorial was this specific motor.

Unfortunately, I'm struggling in finding some wheels that will match these motors. My goal is to build this with this part if possible.

Apologies for the novice question--any guidance would be appreciated.

Thanks!

I purchased a pair of Parallax 4-Phase 12 Volt unipolar stepper motors (http://www.parallax.com/product/27964) with the hope to create a small, programmable vehicle. This was actually an exercise in a novice electronics book and the part mentioned in the tutorial was this specific motor.

Unfortunately, I'm struggling in finding some wheels that will match these motors. My goal is to build this with this part if possible.

Apologies for the novice question--any guidance would be appreciated.

Thanks!

Comments

Still, I think it should be very possible to add a wheel to the stepper motor.

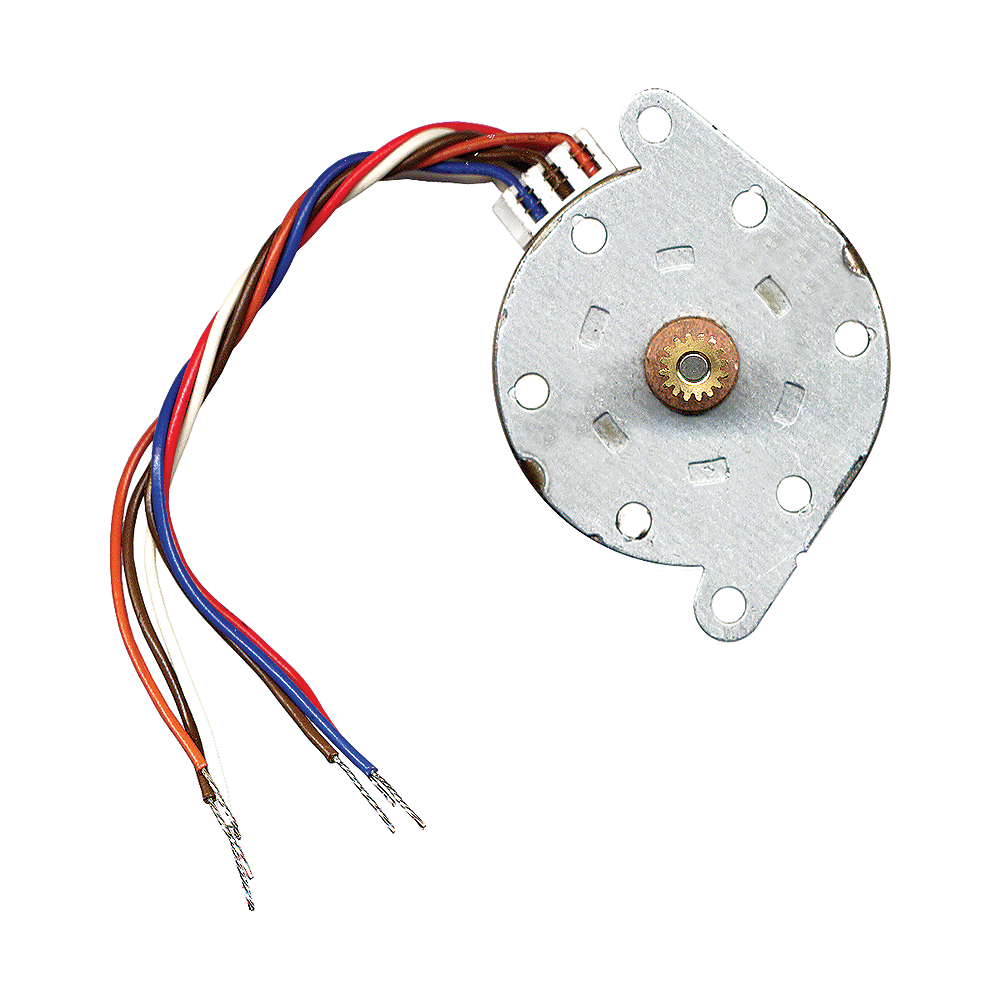

One technique would be to drill a hole a little smaller than the gear on the motor and use a tight friction fit to hold the wheel in place. I'm not sure how well this would work though.

I tried something similar when adding some Vex wheels to a CR servo. There are some pictures of the process in this post.

Another idea is to use Polymorph to make some sort of adapter between the motor and the wheel. There are some links to Polymorph tutorials in this thread.

If you could find gears to work with it, you could use gears to transfer the power from the stepper to the wheels.

If the gear is removable, you might be able to find adapters made to fit the shaft.

I think I'll attempt to create some smallish wheels that fit this gearing using a 3D printer. If I fail miserably, maybe I'll take the Polymorph route.

Do yourself a favor and use a continuous DC motor, already geared if possible. An R/C servo motor, like Parallax's continuous rotation servo, is ideal for most any small vehicle. Wheels are already designed to fit these kinds of motors.

There's nothing wrong with stepper motors, but using them to drive small bots is not one of their strong suits.

GULP. This flies in the face of a new small bot I'm working on now. Will advise, Gordon!

Maybe I should defer to Gareth before continuing. He has made more robots than me and there's a good chance he has already done whatever I'm considering.

Back in the day the (rather hefty) 5V steppers from 5-1/4" drives, for moving the head carriage, were common in surplus. They made pretty good robot motors, but these from Parallax are a lot smaller. Plus they're already rated at 12 volts, so it's hard to over-volt them without adding a lot more batteries.

For a bot of any size and weight, start with a size NEMA 14 single stack motor. They get lots bigger, of course. Just remember these consume more current than other motors you may have used. Also bear in mind that torque is reduced at higher speeds. As you increase their speed to move the bot along, there's a chance the thing will just stop (or more commonly skip steps) because it's underpowered. Increasing the voltage doesn't make it go faster, but it does increase current and torque.

Since I have some experience here I'll chime in. You definitely do have to accept a slower bot on steppers. My bot's top speed is set to about 0.6fps which is on the slow end of most but seems fast enough for indoors. I also geared down with belts to a 4:1 ratio so that my normal drive speed was in the nice smooth range of the steps per second for the motor. Current draw is significant on my NEMA17 motors. In fact these are some of the beefiest motors I have found for the size anywhere. They draw just over 1 amp each at rest, but current falls off rapidly as they speed up. The bot runs on 12V but 16V would have been better.

My little beast is heavy. Over 10lbs but there is little that slows it down, even a 45 degree incline. A few suggestions on stepper selecting:

- High voltage ratings on the stepper means slow as does high inductance. The torque will fall off like a cliff as you try to step faster.

- Low voltage means high current for most practical applications, expect to need more than AA's to power it.

- Use a drive that can enable/disable (High-Z). This saves a huge amount of power that would otherwise be turned into heat while you sit still. If the motors are not spinning don't power them.

- Detente torque helps with the above point. My bot will not roll on most reasonable inclines with unpowered motors. The detente torque holds it in place. Maybe hold with one motor if you must handle a steep incline.

- Gearing is not infinitely effective. You need to keep the motor in a nice band of steps-per-sec. A little can go a long way. I wish now I had done a simple 2:1.

- Gearing reduces detente torque, The higher the gearing ratio the easier it is to move the wheels against the holding force of the motor (with low ratio belts anyway).

- Acceleration is a must if you plan to move at any speed and simple ramps are not nearly as effective as properly calculated accel. I could not move my motors past 300 steps per second without calculated accel. With it I was able to get to 700+ with 12V. Ramps only improved the situation by a hundred or so SPS. You can brute force it some with more juice.

My bot, because it's duty cycle is low, can run for 6 to 7 hours on a 12V 4Ah LiPO battery. I would expect maybe 25% of that if it was to spend it's time constantly rolling. Far less were it to spend any significant time sitting still with the motors powered. I've never found the equal of these steppers again for anything like a reasonable price. I wish I had purchased 10 of them when they were at All Electronics.

I'd agree with Gordon that steppers are not the most ideal of drives. They are heavy and slow, but they do make some things simple like moving a certain distance or spinning a set number of degrees as long as you can accept the lack of feed-back. If you have some other sensors to compensate you should be able to tell if you are changing position or rotating and react to that if it's not happening. I plan to use gryo/compass to see if turns are actually occurring and accelerometer to see if I'm actually moving when I'm supposed to be as substitutes for tracking encoder pulses.

That should work pretty well if you are careful to drill centered and true to the original hole in the wheel. I would imagine filling the space around the gear teeth with epoxy could make for a more secure mount. some grease on the gear teeth would keep the epoxy from bonding to the gear and make it (more) possible to wiggle off later if needed.