Regarding LM317: Not getting required output

Dear All,

I am working on failure analysis of products.

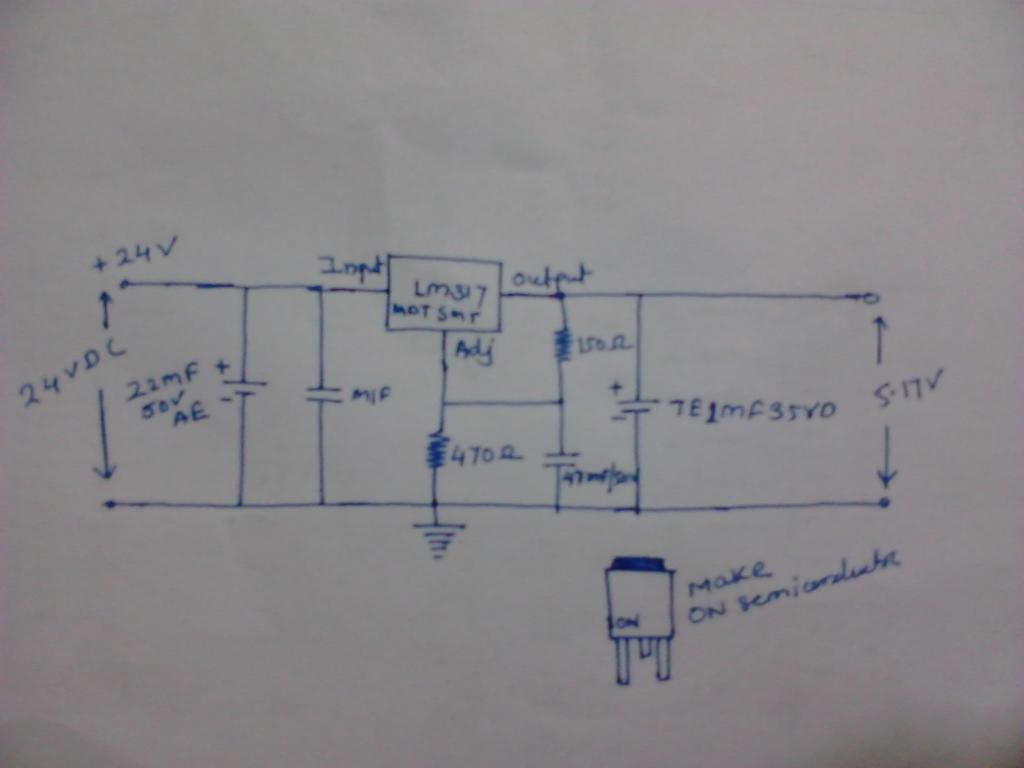

In one faulty module we use LM317 for 5.17 V generation.

The reported problem is that the output voltage is not observed and sometimes it is observed (During vibration)

After analysis it is observed output pin of LM317 is not soldered so sometimes it is get connected and sometimes it is not.

But problem is that when output pin is firm with soldering pad that time at the output voltage observed 10.48V instead of 5.17V.

When output not observed that time output voltage is occurred 0.25V.

When I soldered output pin then everything is working fine and observed 5.17 v exact.

Now i want to know why this happen in that instance I got sometime 10.48 V and sometime 0.25V.

I attached herewith snap of circuit.

Please help me friends it is very interesting problem.

your suggestions and comments regarding this problem is must.

I am working on failure analysis of products.

In one faulty module we use LM317 for 5.17 V generation.

The reported problem is that the output voltage is not observed and sometimes it is observed (During vibration)

After analysis it is observed output pin of LM317 is not soldered so sometimes it is get connected and sometimes it is not.

But problem is that when output pin is firm with soldering pad that time at the output voltage observed 10.48V instead of 5.17V.

When output not observed that time output voltage is occurred 0.25V.

When I soldered output pin then everything is working fine and observed 5.17 v exact.

Now i want to know why this happen in that instance I got sometime 10.48 V and sometime 0.25V.

I attached herewith snap of circuit.

Please help me friends it is very interesting problem.

your suggestions and comments regarding this problem is must.

Comments

Thanks for your prompt reply.

please see attached pic it gives you exact idea about components position on PCB please comment on it

...good question!

Thread moved to General.

A soldered connection is reliably low resistance connection.

A breadboard insertion is a variable higher resistance connection.

You can only do so much on a breadboard to test a concept. It is never a reliable durable solution, especially for power distribution. The contacts get dirty, become looser with age, and so on. The size of the wires you use with a breadboard varies from person to person, so how snug your fit is depends on your awareness of wire size and the 'snugness' of the insertion.

In other words, breadboards misbehave.

Dear Friend,

The ckt not made on breadboard it is proper designed on two layer PCB board. For your reference please find attached Assembly diagram

That comment "When I soldered...." got me to thinking you started with a breadboard, and switched. I realize that English is not your 1st language, it just was a bit unclear what you had stated with.

A Cold-solder joint is yet another variable high-resistance connection. These do happen more often that we would like to see.

When I build a board, I test the voltage output with the regulator in place... but other components that might suffer from an over-voltage not yet installed.

Quite often, my attempts at construction either present an over-voltage from some error in construction. Or the regulator is over-heating from a direct short caused by a solder bridge. This has happened so often that I keep one finger on the regulator when I power up ... just to monitor the heat and to allow me to quickly disconnect power.

These are just the hazards of small production runs with manually soldered components.

In general, a cold-solder joint looks ugly; a good one is nice and tidy. So when in doubt, re-heat the ugly ones until they look good.

Feedback from the output pin helps to determine the output... so unstable resistances cause unusual output.