LM317 Dual ADJ with single POT?

Just a quick question I'd like to check on before trying out....

I use the LM317 regulators alot, typically with a potentiometer between the ADJ and OUT pin to set current.

This time I need to use two LM317's to power two different sets of lights... what I would like to do is use a single potentiometer so that as one is dimmed, the other gets brighter (both could never be full brightness at same time).

The way I was thinking this could be done is with a center tap potentiometer... each LM317 OUT pin connected to the opposite ends of the pot, and both ADJ pins sharing the center tap.

This would create the exact resistance scenario desired to dim one into the other.

Although... I'm afraid they would interfere with each other or worse, parallel the resistance and send all current to a single output.

I' m expecting I'll need a dual output pot... just curious how this configuration would result.

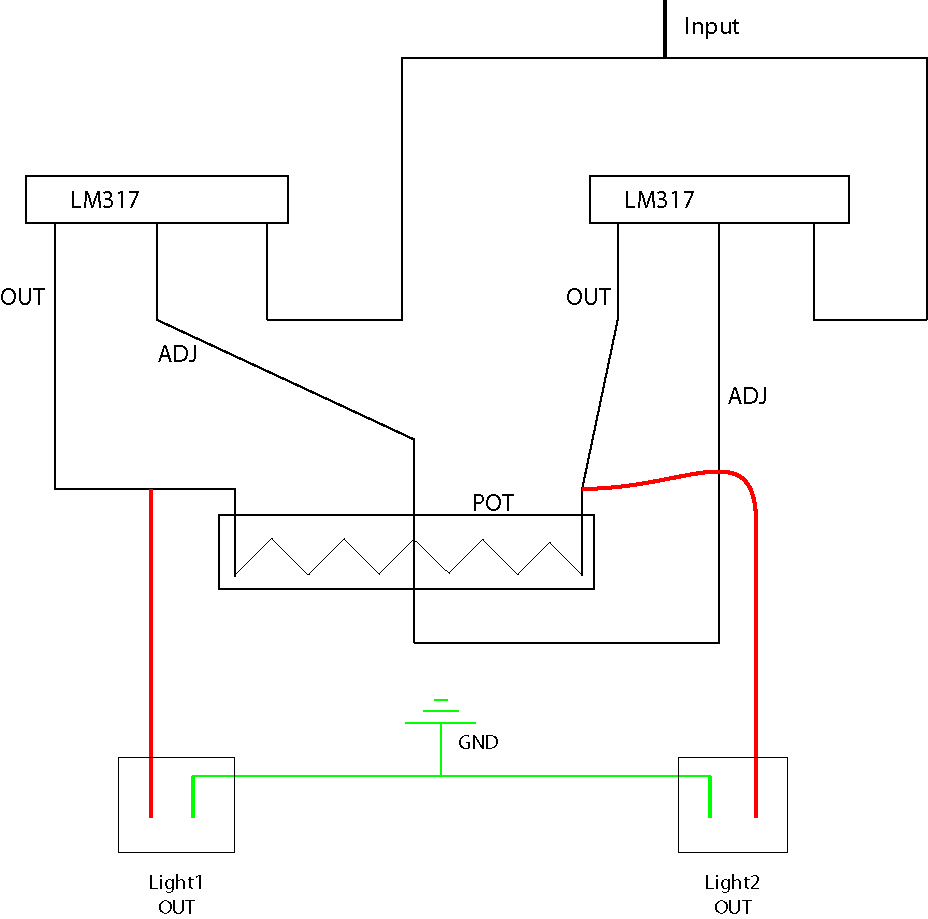

Here is a wiring diagram to illustrate:

I have left out all other components such as cap's, diodes and limit resistors for when pot hits 0.

I use the LM317 regulators alot, typically with a potentiometer between the ADJ and OUT pin to set current.

This time I need to use two LM317's to power two different sets of lights... what I would like to do is use a single potentiometer so that as one is dimmed, the other gets brighter (both could never be full brightness at same time).

The way I was thinking this could be done is with a center tap potentiometer... each LM317 OUT pin connected to the opposite ends of the pot, and both ADJ pins sharing the center tap.

This would create the exact resistance scenario desired to dim one into the other.

Although... I'm afraid they would interfere with each other or worse, parallel the resistance and send all current to a single output.

I' m expecting I'll need a dual output pot... just curious how this configuration would result.

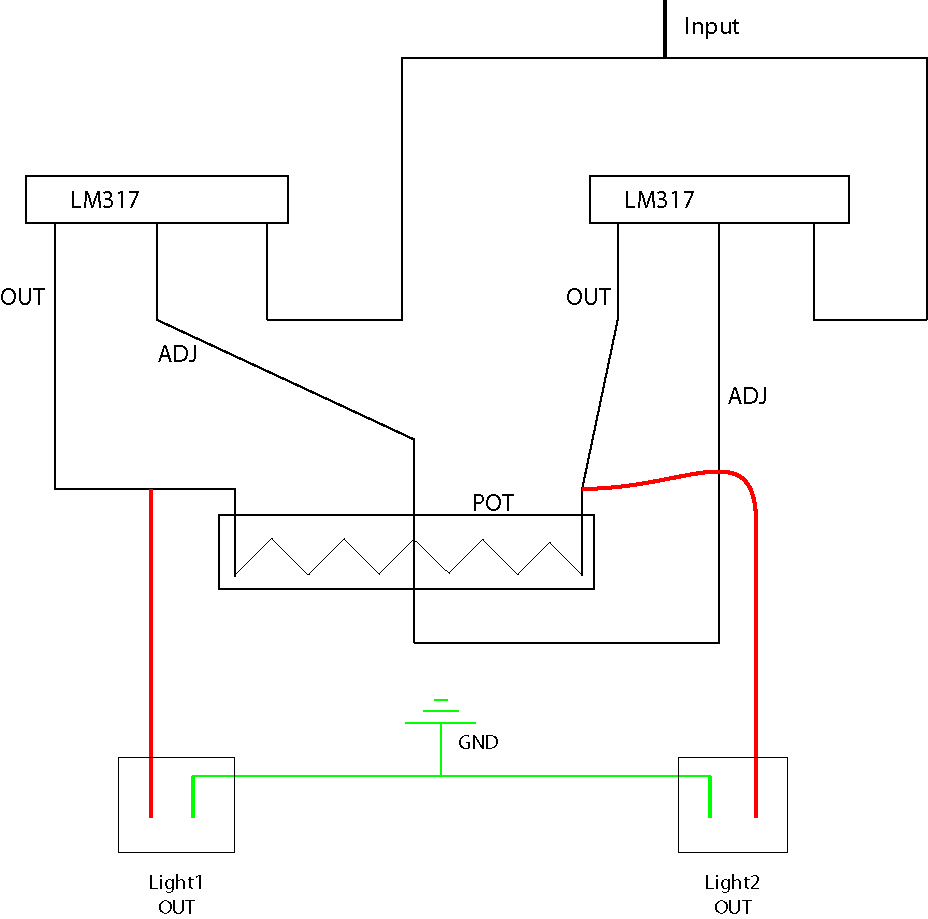

Here is a wiring diagram to illustrate:

I have left out all other components such as cap's, diodes and limit resistors for when pot hits 0.

Comments

Why not use two ganged pots? And make sure to get ones that can handle all of the lamp current. For that reason, it may be better to use the '317s in voltage-regulation mode, since the lamp current would not need to run through the pots.

-Phil

http://physics.gac.edu/~huber/classes/phy270/SpecSheets/LM317.pdf

I think the circuit you propose will work. However, the adjustment current from both regulators will pass through R2, which may be an issue -- I'm just not sure. I'm also not sure that R2 is even necessary. Even with the adjustment pin grounded, the output will be 1.2V.

-Phil

Oh sorry missed that part.... In that case In the schematic that you provided I would remove R2 so that it is NOT common to both regulators, but instead place a separate limiting series resistor on each "outside" leg of the pot

Seems odd though that the pot would connect to gnd, they made the part so I'll take their word for it... but looking at it, wouldnt that create a short?

Doing the math: 1k + 129 = 1129ohm @ max pot resistance, or 129ohm @ minimum pot resistance --> (1.25vref / 1129 = 1ma) or (1.25vref / 129 = 9.7ma)) says between 1ma and 10ma would ground out.

Unfortunately that schematic is for an identical array (all outputs will be the same), which is not what I need to accomplish.

I just realized I mislabeled the 317 pin assignments... from right to left they are IN - OUT - ADJ on a TO220. (I mislabeled them IN - ADJ - OUT)

I have been using it for almost a decade with a pot & limit resistor between adj & out, with the ADJ going to the circuit output... no ground used on the pot. an example of this can be seen by googling "DDL driver"

This provides a very precise and stable; current limited, voltage regulated output (filter caps necessary). I have used it as a continuous power source on everything from custom power supply's to LED's and even high amperage laser diodes.

This is the first time I have needed to control two outputs with a single pot though, and to make it more difficult, their outputs need to be inversely proportional.

I do not see an application example for this in the datasheets, not even the very in-depth one you provided beau.

seems likely I will need a dual centertap pot (1 adjustment, 2 isolated terminal sets... like a DPDT switch)

Curious: Wouldnt R1 & R2 be excluded by the circuit as R3 or R4 is the only path between each ADJ? I have never used a GND in the 317 vref to set a current... but I do see this in application examples.

-Phil

For the values in the post 3 schematic the current from out to adj would be 1.2V / 1K = 1.2mA for both regulators.

If the wiper of R1 is at the left most position the output of the left regulator would be 1.2V since R3 is connected to ground.

The output of the right regulator would be 1.2V + (1.2mA x 1K) = 2.4V

If the wiper of R1 was centred both regulators would output 1.2V + (1.2mA x 0.5K) = 1.8V.

The major concern for this circuit would be to select R3/R4 values that provide a low enough current that the pot is not damaged, but high enough for a stable output voltage. Something in the range of 240 to 470 ohms should work.

PS CuriousOne - Yes the adj pins will be shorted to ground at the edge positions but this is not a problem since the currents are fixed by the values of R3/R4. They produce a constant current between the out and adj pins, and that current through the resistance between the end of the pot and the grounded pot wiper determine the output voltage.

I find the max output voltage is roughly 1.5v minus the input voltage, it stays the same no matter what current i set with the pot.

I always took it as the regulator is using the 1.25v for internal feedback and another .25v is lost from inefficiency margin.

I notice there are many ways to use the 317, some are voltage limited, some are voltage regulated... my example has always worked as voltage regulated, for example I can power a single red led from a 25v source, or a 12v fan from the exact same circuit (current is set with pot: 30ma for led, 150ma for fan).

1. Set the current to, say, 30 mA.

2. Power a 510-ohm resistor with it and measure the voltage across the resistor.

3. Power a 270-ohm resistor with it and measure that voltage.

If the '317 were regulating voltage, the two would be the same. But they will not be because the currents are the same, and Ohm's law says ... Well, you get the idea.

-Phil

What I do know for sure... the higher power laser diodes I use do not have a steady voltage consumption, rather the voltage consumption rises along with current.

If the voltage were to always be fixed, the diodes would not work as current gets increased from 50ma to over 1A... the voltage requirement rises over 2v from threshold to max. And the diode would burn out if the voltage were too high or low in relation to current... laser diodes are very sensitive.

Can you shed light on why I can use the exact same circuit with 25v in to power anything from a very low voltage led (around 2v?) to a 12v fan? I manually set the current output with a pot, but never have to worry about the voltage... only heat dissapation.

Both devices should burn out if the voltage were too high.

In cases where current is a static, monotonically increasing function of voltage, fixing either one will keep the other one constant as long as the load itself doesn't change. But under cases of changing load, you have to decide which to regulate; voltage or current; you can't do both simultaneously. Your LM317 circuit topology regulates current. If the output voltage doesn't change either, it's only because the load doesn't change. In like manner, if the ADJ pin connects to a voltage divider from the output to ground, the LM317 will regulate the voltage on its output pin by virtue of keeping the differential between OUT and ADJ fixed at 1.2V. In this case the voltage will stay fixed, but the current will change if the load changes.

IOW, what you see as "voltage regulation" is merely the inherent consequence of regulating the current to a static load. It's not something the regulator is doing explicitly.

-Phil

I have always thought of it as 'voltage regulated, current limited' because the current is permanently set or 'limited' to one value... and that the voltage automatically gets 'regulated' to whatever the load uses... assumed it could sense what the load uses, sort of like the float switch in a toilet's resivoir tank.

It can, but using the circuit in #3, starting with R2=0, and usually R3=R4=120 ohms

Some things to note on LM317

* It has a minimum load current requirement for regulation, hence the common 120 ohm upper bias values.

* If using the circuit of #3, you will need a low value pot (1.08k for 12V max Vo, 10mA load )

Because 1.08k is not common, you can trade some minimum voltage, for the upper end.

eg R2 = 40 ohms, (10mA load current*2) and a 1k (exactly) pot will adjust to 12V

* Beware of wiper noise, and an momentary open wiper will spike the voltage to the maximum of Vin-Vdropout.

Some largish capacitors on the REF pins, could mitigate this effect.

* Circuit #3 will give complementary tracking voltage output, load current is not defined by this circuit.

* You can use LM317 in Current mode, where you vary the upper divider resistor. ( Io = 1.2v/Ru )

This has no common terminals, so a tandem POT would be needed.

Current transfer is inverse, unlike Voltage above which is linear.

Current Mode has the load current thru the pot, so that's likely a wire-wound pot..

If you want easy adjust of Current, it might be better to find a regulator or driver with proper Current-Set pins.