Simple plastic cover I made for circuit board

I was thinking about what I could use to cover the bottom of a circuit board so that it wouldn't short out when set down on the bench or mounted in a machine. I remember from the old days of repairing consumer electronics products of the stiff insulating sheets they would use to cover circuit boards and they even made a simple "box" out of the same stuff to cover assemblies.

So I thought about what I could use that would be similar and easy to find locally. After some thought I went to Staples and purchased their cheapest 3 ring binder ($1.99) that was made out of thin translucent plastic. They are the Simply brand 1/2" Poly available in different colors.

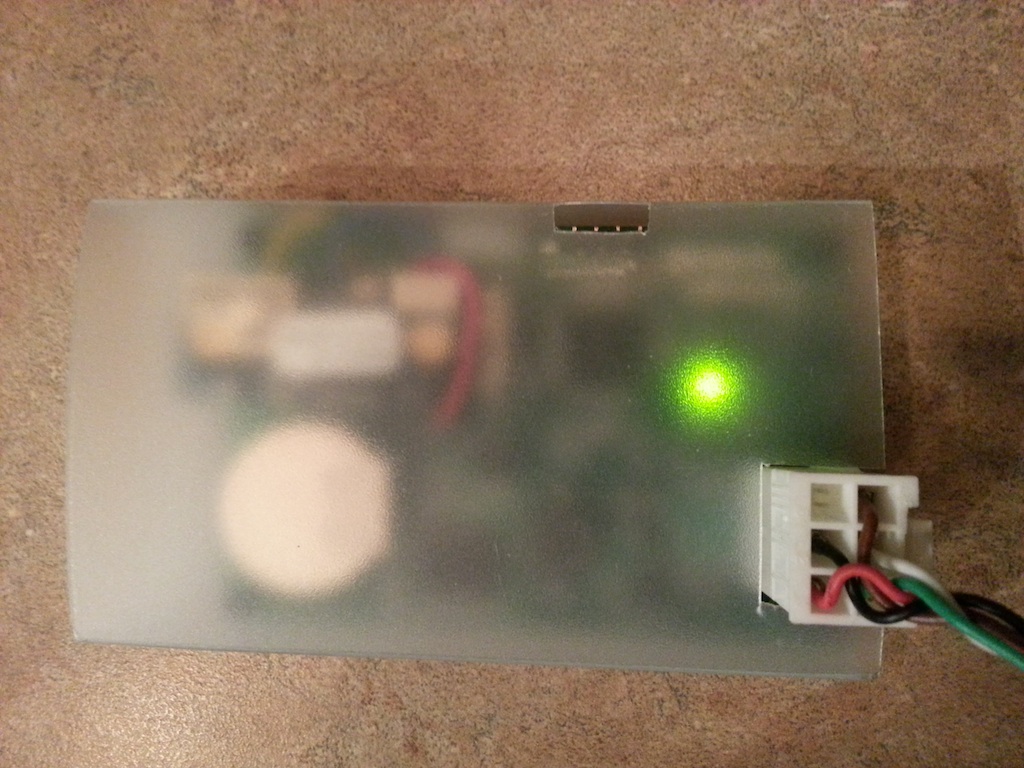

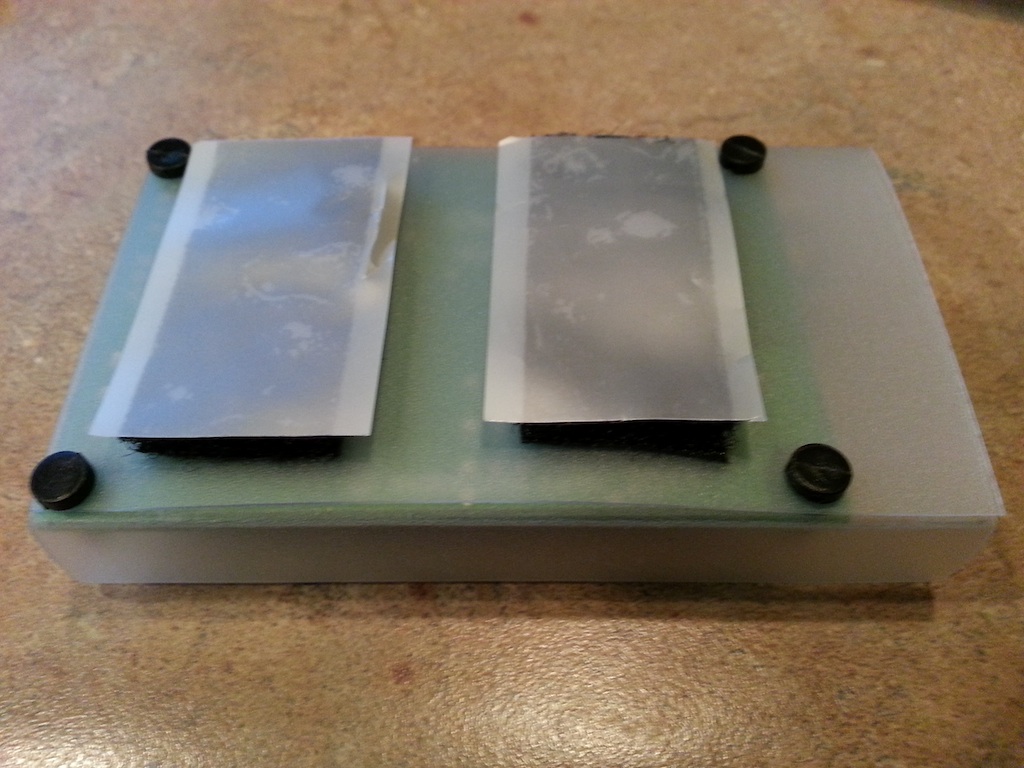

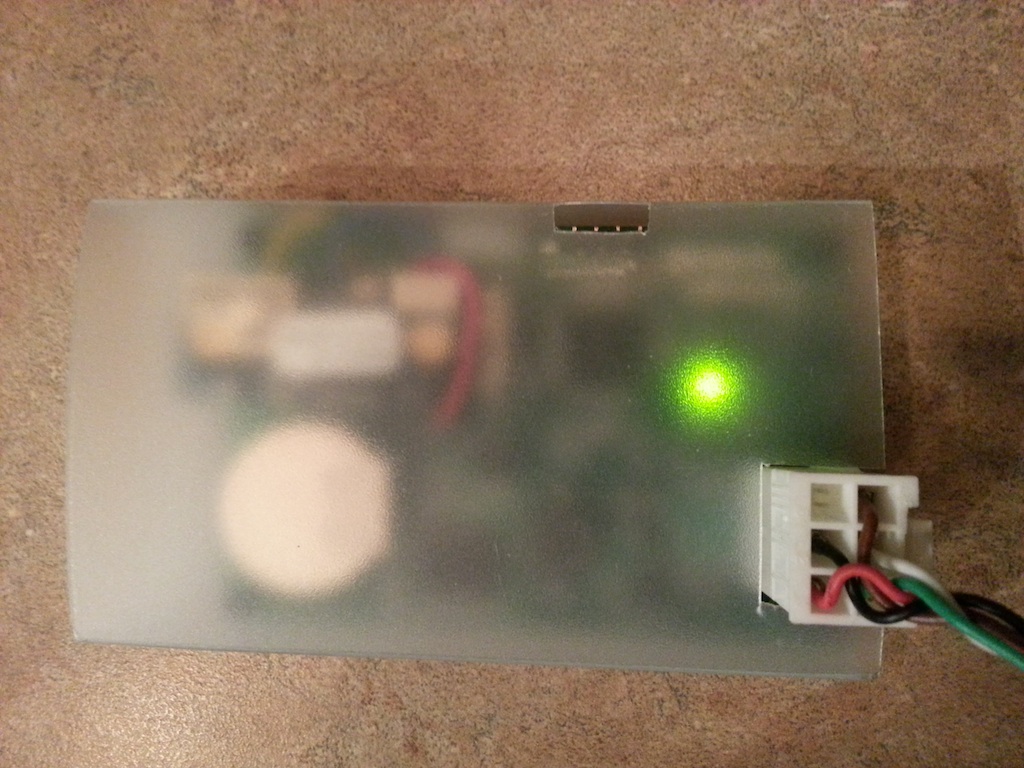

So I sheared the pieces with my paper cutter to fit my board. I was able to bend the corners and make a creased edge to form somewhat of a square edged box. I used an Exact-O knife to make a couple cutouts. I found some small push though fasteners at the local hardware store to hold the plastic to the bottom of the board.

It worked out pretty cool. It's simple, provides protection against short circuits and is translucent to allow the led's to shine through. I attached some Velcro strips to the bottom for mounting.

Now if I could find a way to label this type of plastic. I'm not sure what could be used. Any ideas? I was thinking of some sort of heat stamp but don't know how that could be done easily at home.

So I thought about what I could use that would be similar and easy to find locally. After some thought I went to Staples and purchased their cheapest 3 ring binder ($1.99) that was made out of thin translucent plastic. They are the Simply brand 1/2" Poly available in different colors.

So I sheared the pieces with my paper cutter to fit my board. I was able to bend the corners and make a creased edge to form somewhat of a square edged box. I used an Exact-O knife to make a couple cutouts. I found some small push though fasteners at the local hardware store to hold the plastic to the bottom of the board.

It worked out pretty cool. It's simple, provides protection against short circuits and is translucent to allow the led's to shine through. I attached some Velcro strips to the bottom for mounting.

Now if I could find a way to label this type of plastic. I'm not sure what could be used. Any ideas? I was thinking of some sort of heat stamp but don't know how that could be done easily at home.

Comments

...ditto! :thumb:

Thanks for sharing.

http://www.ebay.com/itm/Multi-RC-Helicopter-Plane-CCPM-Servo-ESC-Consistency-Tester-Checker-4-8-6V-/390717141894?pt=Radio_Control_Parts_Accessories&hash=item5af88e7386

http://www.menards.com/main/tools-hardware/fasteners/hard-to-find/clips/7-64-hole-flex-retainers-10-pcs-box/p-1653776-c-9548.htm

I'd like to find a much better price on quantities. Seems rather pricey for a little piece of plastic.

What about using nylon nuts and bolts to secure the board to the plastic?

I get a lot of stuff from Micro Fasteners and they have nylon nuts and bolts.

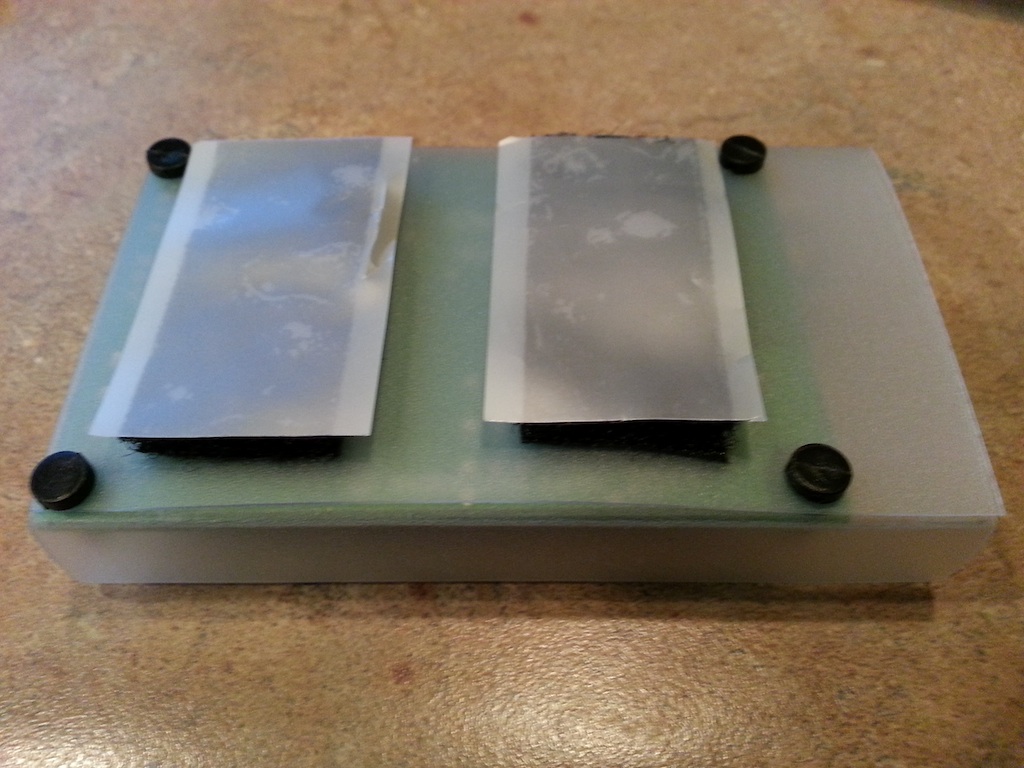

You got my interest with this one so off to the Dollar store I went today. I found some sheets that appear to be made from the same material. The notebook binder cover material I used is .015" thick while the cutting board material from the Dollar Store is .017" thick.

The cutting board material should work great at even a better cost savings. The white/opaue larger style even has one smooth side. They also had a 3 pack of smaller colored ones too.

Thanks for the tip!

Duane- yes that would work too. The push in type fasteners are nice for quick assembly. Seems the size I need though is more expensive than the larger sizes. I paid $.63 each yesterday at the hardware store.