Wally

Hi All...

I tried starting a blog about building a bipedal 'bot, but for the life of me I couldn't figure out how to get jpegs to display, so i'll put things here in the forums.

The idea came about while surfing eBay looking for a robotic arm. I saw some of the walking robots and thought "This is cool!". Starting out, I'm using six Tower Pro MG996R servos controlled by a Stamp BOE with a BS2P through a Prop Servo Controller USB. The design started out to have 6 DOF (Hip, knee and ankle 1-dof each / hip and knee rotate in pitch and the ankle rotates in roll) but the more I researched, the less I liked the gait. It was a lot like the walk of the Penguin and I hoped to achieve something a tad more human like. That said, I want to add pitch to the ankle... this will add another servo/bracket set to each leg (have to order more brackets because of my short sightedness :-| )

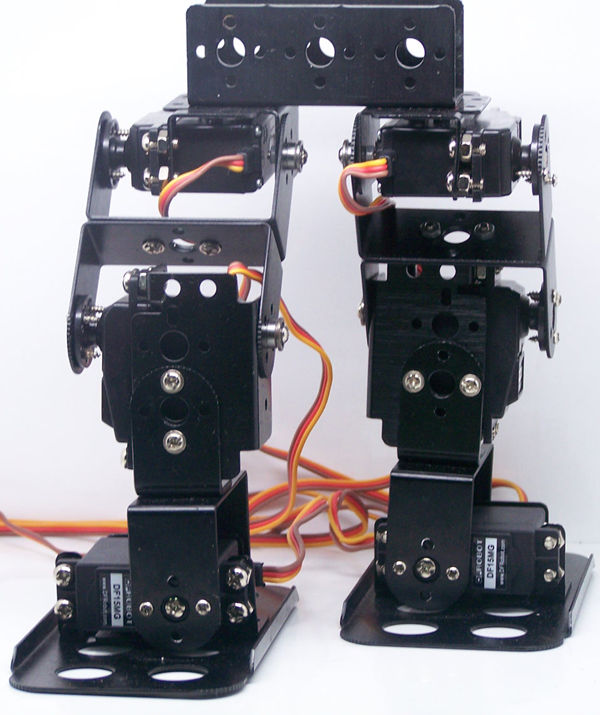

Wally, initially, will look like this guy:

The differences? This 'bot goes for $299.99 on eBay, but you get free shipping! By picking and choosing my parts sources, I'm just bit over $100 into the project. It helped to have a couple of bracket sets and a Stamp board with two Prop Servo Controllers already on-hand.

Other things... I'm using hi-torque servos with metal servo horns and ball bearings in all joints.

The majority of parts are scheduled to be delivered tomorrow and I'm anxious to get started!!!!

@

Edit: Well Pooh! Tomorrow is a holiday with no mail delivery.

I tried starting a blog about building a bipedal 'bot, but for the life of me I couldn't figure out how to get jpegs to display, so i'll put things here in the forums.

The idea came about while surfing eBay looking for a robotic arm. I saw some of the walking robots and thought "This is cool!". Starting out, I'm using six Tower Pro MG996R servos controlled by a Stamp BOE with a BS2P through a Prop Servo Controller USB. The design started out to have 6 DOF (Hip, knee and ankle 1-dof each / hip and knee rotate in pitch and the ankle rotates in roll) but the more I researched, the less I liked the gait. It was a lot like the walk of the Penguin and I hoped to achieve something a tad more human like. That said, I want to add pitch to the ankle... this will add another servo/bracket set to each leg (have to order more brackets because of my short sightedness :-| )

Wally, initially, will look like this guy:

The differences? This 'bot goes for $299.99 on eBay, but you get free shipping! By picking and choosing my parts sources, I'm just bit over $100 into the project. It helped to have a couple of bracket sets and a Stamp board with two Prop Servo Controllers already on-hand.

Other things... I'm using hi-torque servos with metal servo horns and ball bearings in all joints.

The majority of parts are scheduled to be delivered tomorrow and I'm anxious to get started!!!!

@

Edit: Well Pooh! Tomorrow is a holiday with no mail delivery.

Comments

Introducing Wally!

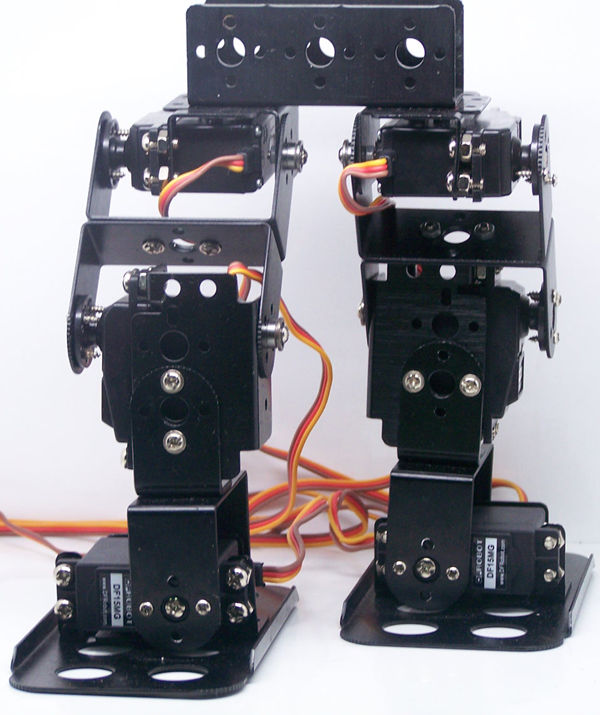

This is kind of where I'm starting with my biped 'bot. This is just a test fit looking for clearance/alignment problems.

The metal servo horns still haven't arrived so I'll be tearing him down to install those as well as rejiggering the layout a bit to allow for adding an upper torso and =possibly= a couple of arms.

I mechanically centered the servos before this assembly, but that didn't work very well. (Okay I was in a hurry to see him assembled. I'm one of those nerds who buys some toy at the geek store and walks to the car unwrapping it so I look at everything as soon as possible!!)

I need to fabricate something to mount the electronics and I'm still looking for a small, powerful battery pack. I'm not sure running 6 servos from 4xAA is the best plan. :-|

@

The Aluminum servo horns arrived today...

I test fit one on an old servo with a metal output shaft. Wow! Do they fit tightly. Took a serious bit of BFFI to get it back off the servo. Don't think you would really need the mounting screws to hold them on.

I think when I put them on Wally, I'm going to put a bit of lithium grease on the spline.

Can't WAIT to see your GAIT!

Yup. All my critters have to have names. Trying to think of a good project for Oglethorpe! ;-)

@

Even having to disassemble the legs, I managed to install the aluminum servo horns with almost no harsh language. Okay... there was that one point when I realized I'd reassembled two left legs, but that's all... I promise! :-)

Managed to get the servos to make a couple of basic moves, but nothing near actual walking. This project makes me appreciate the complexity of the human body =:-|

First problem... the servos move =way= too fast. I've tried adjusting the 'ra' value in the PSC commands, but it doesn't seem to make any difference. Anyway... more work ahead.

A short video of Wally standing up. Not difficult, just centering the servos on power-up. (Wish I had this much energy getting started in the morning!!!!)

Right you are!!! :-) For the moment though, I'm dealing with repeatability issues. That is, each time I energize the system I'm not exactly sure what the servos are going to do! I have the PSC centering the servos on power-up, then if I run a BS2 program to center the servos, they =might= not move OR they =might= move to some other position.

Then, I have the servo ramping speed set to 32... a mid range value that should force the servos to move at a "kind of" slow speed. Not so much... Sometimes the servos move slowly and other times they =snap= into position like into my video clip.

This is so much fun! :-)

Now working on creating all the subroutines to (hopefully) turn all these notes into one smooth step!

@

The smartest thing I did lately was a small but crucial detail on my four-flamethrower project for Halloween. A 9-gram servo blips each aerosol can with the servo horn. I tested the servos and found that on powerup, they all twitch clockwise. To avoid undesired firing on powerup, I purposely oriented the servos so that they fired from counterclockwise motion, and the clockwise powerup twitch would move the servo arm away from the firing position. http://www.youtube.com/watch?v=mHKNzyjM228

Yeah, I've found Wally's servos exhibit the same clockwise twitch... took me a bit to figure out what was going on. I have the PSC set to center the servos on power-up, but there is a difference between applying power to the servos and actually having the PSC send them a command. Also I may have to rethink the "center on power-up" thing (which is probably fine for smaller projects). That snap to attention action gives me a warm feeling as commander of my robot army, but on a crowded desktop, not so much. He's managed to knock over several things including my coffee cup which was, thankfully, empty at the time. And... if start adding an upper 'torso", well that's going to be a whole lot of hardware flailing about at high speed.

I think the biggest thing to overcome for walking is going to be balance. Right now shifting weight to lift one foot off the floor, requires both feet rolling in the same direction to move the center of gravity far enough to balance on one foot. There's gotta be a better solution!

Anyhow, 'tis late and sleep beckons.

Amanda

Thanks shimniok!

This is easily one of the most complex things I've tried to build and it's demanding quite a bit of my time. Fortunately, I'm mostly retired and time isn't the issue it used to be.

Not several bags of nerdy bits and pieces, but a fully assembled and (almost) ready to run little robot. Dang it, I just can't force myself to take him apart! I shall name him "Scooter"!

@

He was like $100 with $6 shipping. A list of what was included:

Robot full bracket 1 set (with 4 aluminum servo horns)

4 MG996R servos

32-channel servo controller

USB cable

Lithium Battery

High-power charger

IR Sony PS2 controller 1 (with IR receiver)

Rocker Switch

Cable Ties

Heh... my roommate made the same suggestion, but none of "the kids" seem to want to be the "6 Million Dollar Bear". Still, I have to admit a robotic teddy bear with laser eyes would be pretty darned cool! :-)