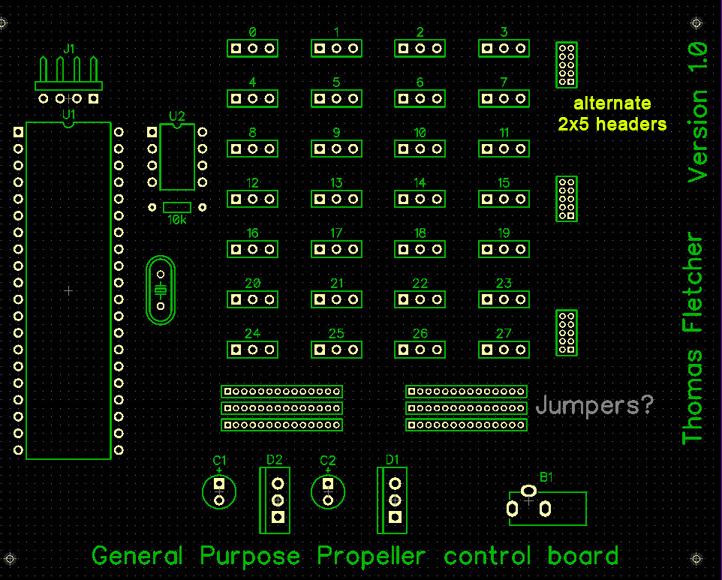

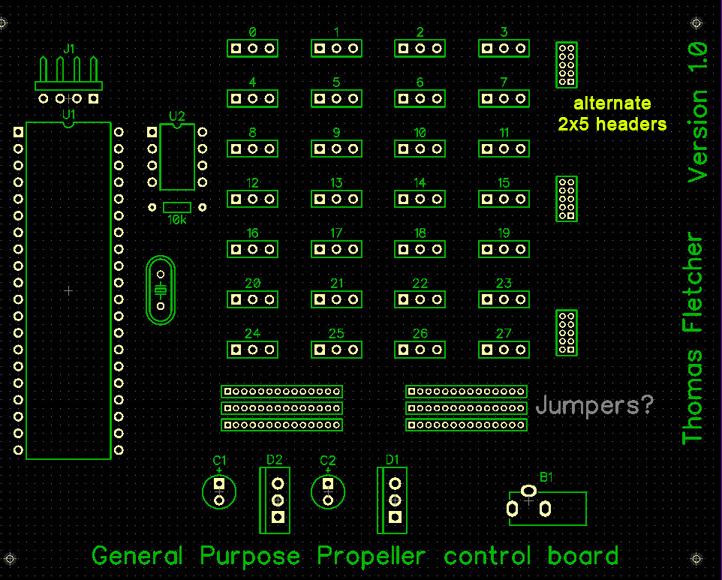

Need advice on creating simple PCB

I was playing around with diptrace and thinking about a general purpose board for the propeller. I have a tendency

to play musical chairs with my hand soldered control boards and was thinking of something that could be easily

plugged in and out of projects.

I would like to access the propeller pins in one of two ways. Either through servo connectors (gnd, power, signal) or

by 2x5 headers.

I was thinking of adding a jumper (28 jumpers) to route the pin to either connector, but was wondering

if that is really necessary if I am just going to use one or the other.

I am hoping picture explains myself better.

to play musical chairs with my hand soldered control boards and was thinking of something that could be easily

plugged in and out of projects.

I would like to access the propeller pins in one of two ways. Either through servo connectors (gnd, power, signal) or

by 2x5 headers.

I was thinking of adding a jumper (28 jumpers) to route the pin to either connector, but was wondering

if that is really necessary if I am just going to use one or the other.

I am hoping picture explains myself better.

Comments

Having them side-by-side means you can just solder in 3 long headers rather than lots of length-3

headers separately.

Why use jumpers? Just connect the pins to both styles of header - you can use either or both

simultaneously.

-Phil

is the things being controlled are on another board or boards.

I am more concerned on keeping it simple for me to use. I have a bad habit of inverting things which

doesn't go well with this hobby. I don't like that the grounds would be in a different orientation

depending on side of chip they are on.

I like also like the idea of "Jumpers" inline with the servo pins; but I would have just 28 pairs of pads, for a total of 56 pads.

I would space the "pairs of pads" so that 28 current limiting resistors could be soldered on the board, if needed.

A very thin "trace" between each "pair of pads" could be placed on the board, if no resistor is needed the Prop pins are automatically connected to the servo pins.

When you need a current limiting resistor you cut the track, and install the needed resistor.

Wouldn't be nice if DipTrace would create a schematic from a layout?

It's so tempting to just jump in with the layout. (Which I still frequently do with small projects.)

-Phil

figure out how to lay ratlines at first.

For something this simple it seems a wasted step as most of this thing is physical connections.

I couldn't find headers in the schematic library I guess for that reason.

I don't put reset or on/off switches on my boards. Always just unplugged.

Totally agreed.

But then I sometimes do it backwards anyway...

Good idea, and if each group has jumpers for the V+ different voltage requirements for peripheral boards could be accommodated.

Short of using some form of polarized connector that`s a tough problem to resolve. A 4 pin servo connector with one location blocked/missing would do that but takes more space.

I find all but the simplest projects end up being an iterative process between the schematic and the layout. Draw the schematic - lay out the board - find troublesome connections - modify the schematic - continue lay out......etc.

With servos they seem to be pretty standardised with red, white and black wires, so you could put some text on the board "Red", "White" etc next to each header. Would need to be a smaller font.

My little quirk with designing PCBs is to try to put enough text on the board so that when I make it up a few weeks later, I don't need to refer to any schematic or board layout while I am soldering. It sometimes takes a while adding labels and moving text around when labels end up on top of each other but it makes soldering so much easier.

As long as you keep the power line on the center pin of a three pin header, then reversing the connector should cause much trouble. Usually it doesn't hurt anything if ground and signal lines are switched (at least I think it's not likely).

This is what I also do when I discipline myself to make a schematic first.

I'd probably use a schematic on this particular board Ragtop is designing. I have a couple basic Propeller templates to use as starting place with boards like these (though I doubt I have any for the Prop in a DIP package).

I agree 1000%. Although, to be technical, I do the prototype on a napkin or paper first then the PCB software is fired up. ;P

have ground, 5v, 3.3v, and 7 of the propeller pins.

The first board was $35, but this one is only $15.29 at 1.9 x 2.7 inches.

Also may I inquire where the PCB will be made ($16 sounds like a good price)?

I second the motion.

There are several I2C objects which require pull-ups on both lines.

The Prop should have a 0.1uF cap near each of its Vdd pins and the EEPROM should also have a 0.1uF cap near it's Vdd pin.

You could sure shrink the board if you are willing to use surface mount parts. The smt Prop with leads isn't too hard to solder (well, it's not hard once you've done a half dozen or so).

I don't disagree 100%.

I tend to start with a schematic to make sure that I have all the basics covered (bypass caps, pull-ups on SCL and SDA, etc.). I will often complete sub-circuit connections, nets that I know have to be connected -- but other than the programming port and the EEPROM pins, I don't connect anything to the Propeller. From there I start the PCB, arrange the components, then go back to the schematic with the ideal nets. It's a back-and-forth process -- all art is, and I look at creating a PCB as much an artistic endeavor as technical endeavor (both aspects must be attended well).

There are many roads leading to Rome, and many roads to a successful PCB.

I have completed almost 60 PCB's and never have any of my clients had a negative comment in over 9 years of, designing boards, schematics and circuits. I use to do the schematic first but found that during the PCB stage many changes happen including the clients productions assembly capabilities. Im no Rookie my friend

I like paper first then PCB then schematic - It provides, me at least, a rapid time to production.

I have been just using Parallax's schematic which just has one 10k for the eeprom. Is there another schematic out there?

It is through the diptrace program. It says from Bay Area circuits. I haven't run traces yet....assuming they charge you for that size copper if

you use it or not as traces......but it might be more when I lay the traces.

The QuickStart schematic is pretty close to what you'd want.

The only Propeller board I'm aware of, Parallax produces, without a 10K resistor on both I2C lines is the Demo Board. All the other Propeller boards use two pull-ups.

The second pull-up isn't needed to program the Propeller but there are lot's of applications which require both lines to be pulled high.

One of the first things the PEK does when it introduces datalogging to EEPROM is to show how to add the second pull-up. Technically, both lines are supposed to be pulled high on a I2C bus.

The lack of capacitors on the Parallax schematic is very annoying to many forum members. Not including caps on each Vdd pin can cause damage to the Propeller (this has been well established). With the DIP chip, you only need two bypass caps on the Propeller. The other packages require four bypass caps (or a power plane under the chip with a ground plane on the bottom layer like the Propeller Proto Board).

In general, each IC should have a 0.1uF bypass cap next to its Vdd pin. So you should also add one to the EEPROM.

Have you tried OSH Park. They're great for small boards. They do take about three weeks to have them delivered. They give you three PCBs for $5 per square inch (or $1.67 per square inch for each board). I've had a lot of small PCBs made which cost around $0.25 each (this includes shipping). The 25 cent PCBs were 1/2" in diameter. For larger boards, I use other fab houses.

It's in the Help menu of the Propeller Tool.