PC + Ethernet + Propeller = CNC

ManAtWork

Posts: 2,297

ManAtWork

Posts: 2,297

I know there are already several projects that use the propeller for CNC applications. Although the propeller has enough power to perfom nicely as a "stand alone" controller and beeing able to run G-code from an SD card without a PC also has some advantages, but I decided to do it a bit different.

The propeller is ideally suited for controlling hardware, generating PWM and step/dir signals with excellent timing and much more. But there are also other things a PC can do better: GUI and processing large amounts of data. So the obvious solution is to divide the task and let each one do what it can best.

The PC provides the user interface and visualisation of the toolpath.

The propeller does all the time critical signal generation and communicates with the PC over ethernet.

Step and Dir signals are routed to the servo and stepper motor drives which are, of course, also propeller based.

Here is a video of the machine in action. Unfortunatelly, it was really loud there so you can't hear that the servos were running almost silently.

The propeller is ideally suited for controlling hardware, generating PWM and step/dir signals with excellent timing and much more. But there are also other things a PC can do better: GUI and processing large amounts of data. So the obvious solution is to divide the task and let each one do what it can best.

The PC provides the user interface and visualisation of the toolpath.

The propeller does all the time critical signal generation and communicates with the PC over ethernet.

Step and Dir signals are routed to the servo and stepper motor drives which are, of course, also propeller based.

Here is a video of the machine in action. Unfortunatelly, it was really loud there so you can't hear that the servos were running almost silently.

Comments

Any more details?

Why mix servos and steppers?

Is there feed-forward?

Cutter comp?

Props closing the servo loops?

Maximum 5 axis?

Regards,

Mickster.

Thanks! It's just a demo to show it is possible. Normally, you won't mix servos with steppers on the main (XYZ) axes. But why not save some money for less important things like the tool changer by using steppers? Even with servos I'd install two sensors to check if the tool changer disc has reached the final position AND the pocket is empty before dropping the tool. This avoids damage where the spindle crashes into the jaws or into a full pocket. So there's no need for a servo.

You mean velocity feed forward in the position loop? Not at the moment. I ran out of cog code space but I think I can squeeze it in after some optimization. There is also no room for a second feedback system (glass scales) due to lack of cogs and pins. But as only few people really need this I'll implement it with an external board and an extra prop. I've already done a DRO project with a prop reading sin/cos (1Vpp) glass scale signals directly (without expensive interpolator, Heidenhain calls it "exe"). So technically this would be no problem, I just don't have the time, at the moment.

BTW, the servos in the video have single turn absolute encoders with 17bit or 131072 steps/turn resolution. They have a proprietary serial protocol which would require an asic/fpga without the ingenious bit-banging ability of the propeller. The high resolution enables a very stiff velocity control loop with almost zero noise even at very low speeds. The servo controllers also support standard incremental and sin/cos encoders. I planned to also support resolvers but it didn't work well. I used the sigma-delta RC method of the propeller to do AD conversion and it has too much noise for the required resolution. The next version will have an optional external 16 bit ADC.

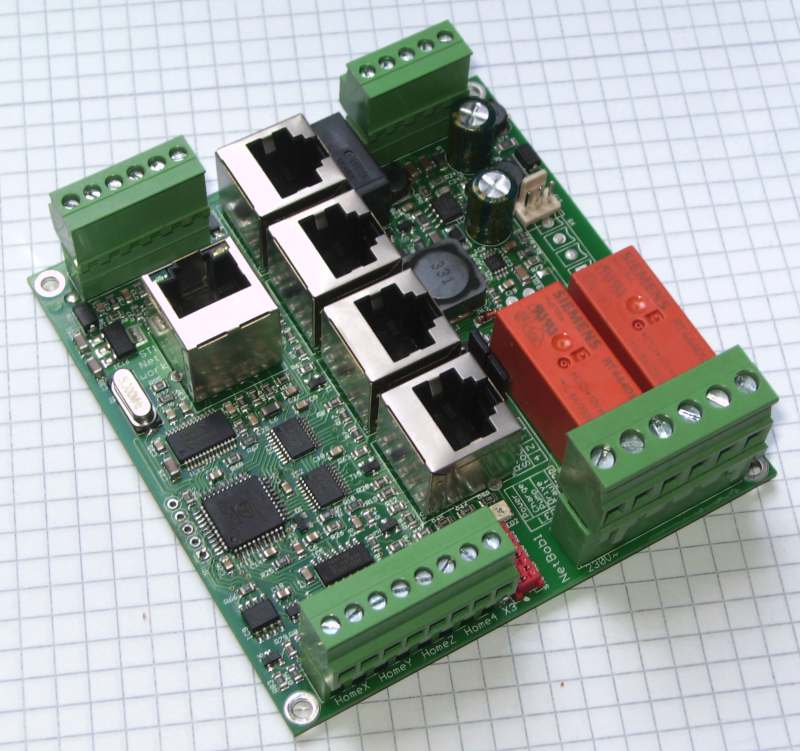

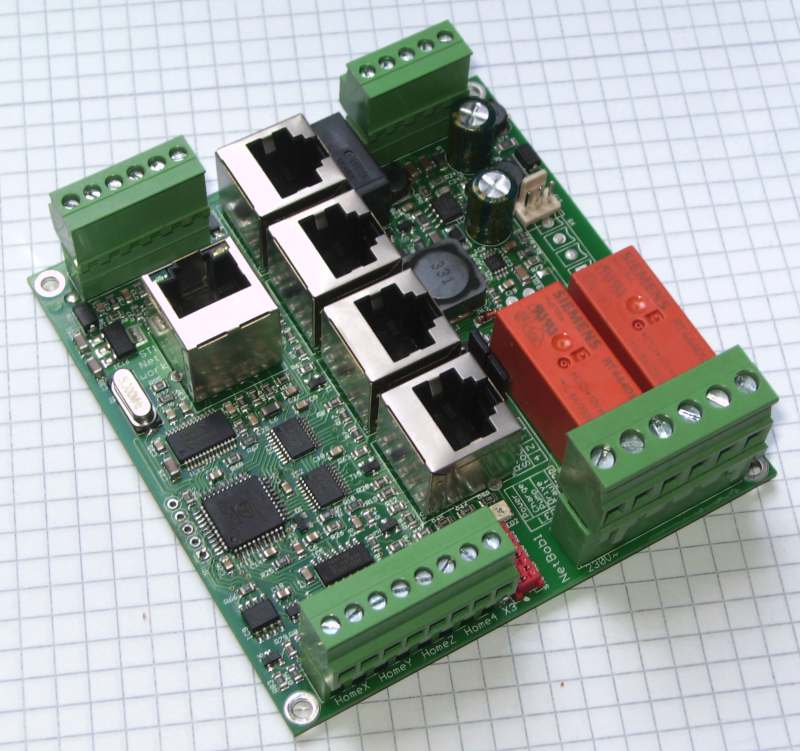

Yes, the software supports cutter length and radius compensation. The current board only has 4 axes since this is sufficient for most applications. I have enough cogs left to support 6 (synchronized and interpolated) axes if required. For auxiliary axes that don't need tight synchronisation you could theoretically cascade multiple boards.

An interesting feature which took considerable development time ist that the communication is not based on TCP/IP but uses a special protocol. This means you don't have to worry about IP numbers. All modules are recognised fully automatically. The protocol is highly fault tolerant. For example you can pull the cable and plug it into a different port of the network switch. If you're fast enough not to provoke a timeout the machine doesn't stop or hickup. And even in the case it does the propeller stops the machine with proper deceleration ramps so you can recover without loss of position.

no ManAtWork does not bring back some tips/tricks from the job. Its opposite. He brought the propeller-chip to his working for a living job.

Maybe the complete CNC-machine is not (yet) an economical success. But I think the prop-based stepper- and servo-controllers ARE a success.

Show me any other stepperdrivers with these specs and prices:

3axle 55V 5A 1/10-microsteps price: 265Euro = $358

single axle: 80V 10A 1/40 microstep real sinewave conversion 150 Euro = $203

single axle 160V 10A 1/10 microstep real sinewave conversion 195 Euro = $264

Have a look at http://benezan-electronics.de/test/Products_de.html

best regards

Stefan

It has no Propeller but an Atmel MCU so I decided to ban it.

Seriously... I thought the new servo controller was available before the stock has been sold out but I was wrong.

I am a serious prospective customer but I find it difficult to understand your products and I don't get replies to my email enquiries.

I build/rebuild/retrofit machinery for a living but have no use for stepper motor based systems. Your OP on this thread suggests you support servo motors but your website no-longer shows any of your own products to be servo related. I understand that your site is under construction so maybe this stuff isn't listed yet(?)

Regards,

Mickster

Huh? I received your mail on monday 30th at 14:14 CET and replied 15:42 the same day. If anything was lost or forgotten, please send it again or try the forum message system.

We are taking a similar track making custom controls for specialty machines for my shop, we are just not nearly as far along as you are.

Please keep posting your progress, it is inspiring.

Doh!!! My apologies. I have a dedicated folder for your emails that I had forgotten about and for some reason I don't get a notification either on my PC or my phone.

Well with all respect and the fact that I feel like I have been publicly reprimanded:

I fully agree that this forum should be for discussing Propeller-related products only and I resent being accused of not respecting this.

Mickster