Meet the New "Motor Mount and Wheel Kit 2" and "MMWK-2MP"

Hi all you MadeUSA and Eddie Aficionados...

So it's no secret that we're re-vamping and upgrading and changing and...and, well, since Ken alluded to "a lower-cost MadeUSA base with molded plastic wheels". .

Here you go :-) this'll give you something to "chew on" over the long weekend...

The original motor drive system was based on some drive motors that were discontinued by the manufacturer. We searched the world, and nearest galaxy's - to no avail - we needed another source - along with that came the necessity for a new Motor Mount and Wheel Kit design.

But along with that, we needed to maintain "upwards" compatibility - at least as much as was economically possible.

So, this is what we had: The "Motor Mount and Wheel Kit"...

It has served us very well over the years.

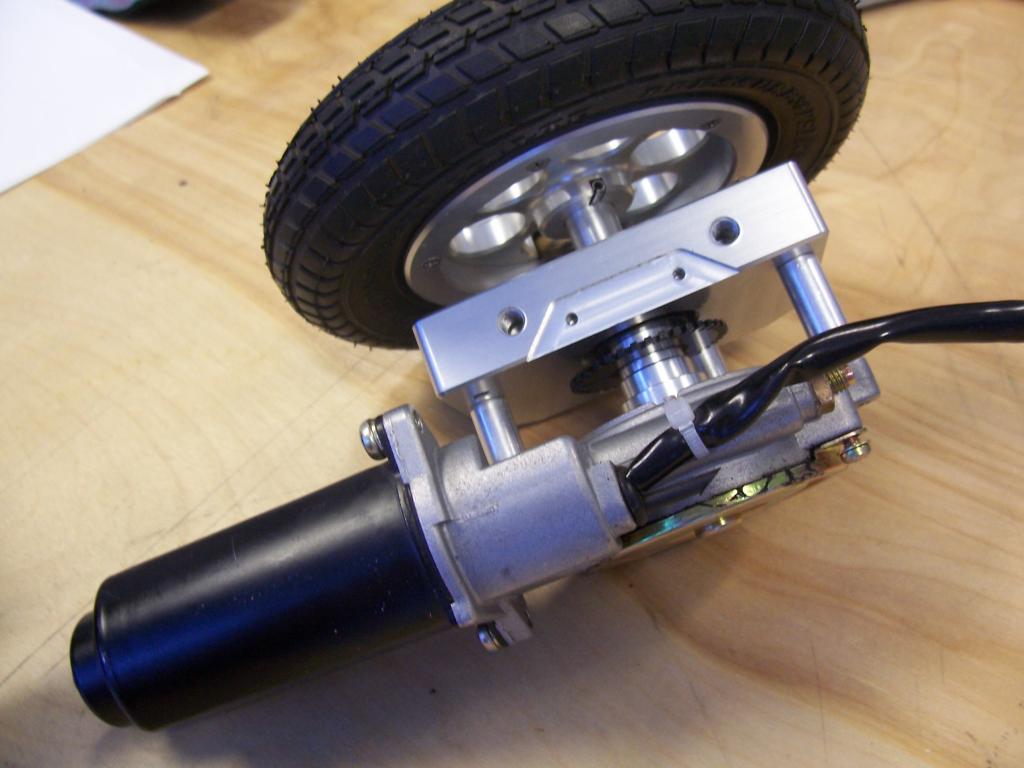

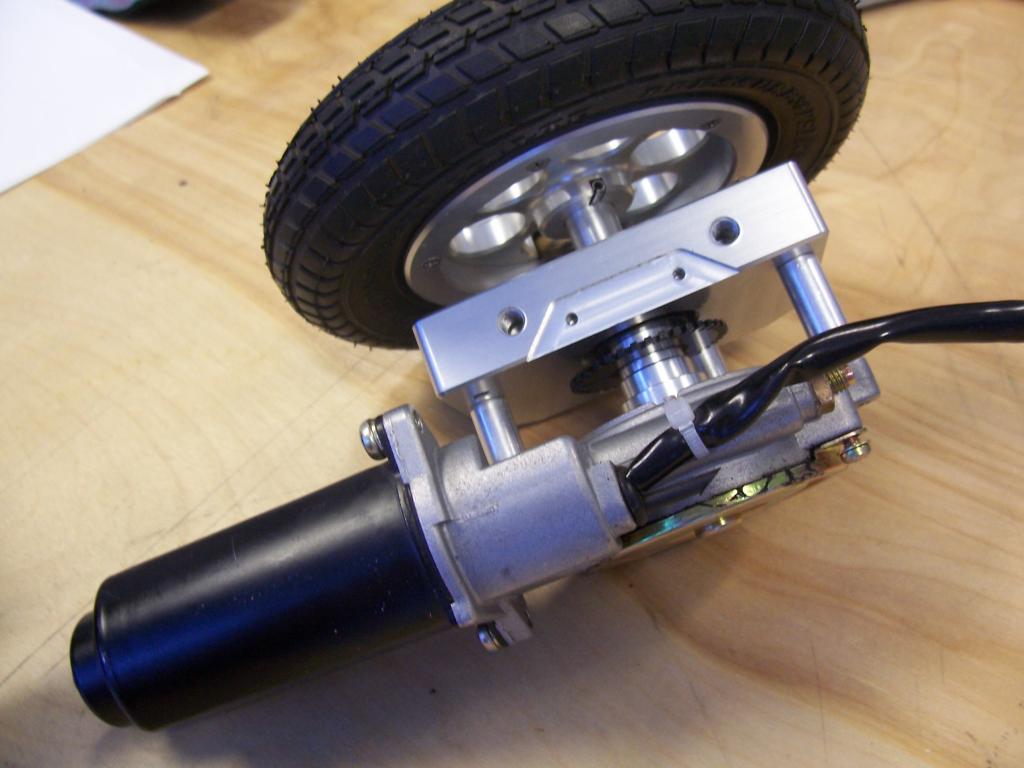

Now, this is the new Aluminum version with the new motors: Motor configuration is very close to the original, and in fact, mounts with the same size blocks and same hole mounting locations. That is to say that the motor mounts to the block in a similar way, but those holes are in different locations.

The Blocks however, have their mounting holes (that attach the drive assembly to a robot base), in the same locations as the original MMWK.

This is what the new motors look like when mounted to the new Aluminum motor mount blocks. Again, different hole locations for motor to block, but same hole spacing from block to what you choose to mount it to...

Oh, and The Aluminum wheel assembly (split ring hub) remains the same, and accompanies the Aluminum motor mount block system, just like before. This new kit has a "Solid Supplier of Motors" (that are currently in production) - no worries about Rev C for a while.

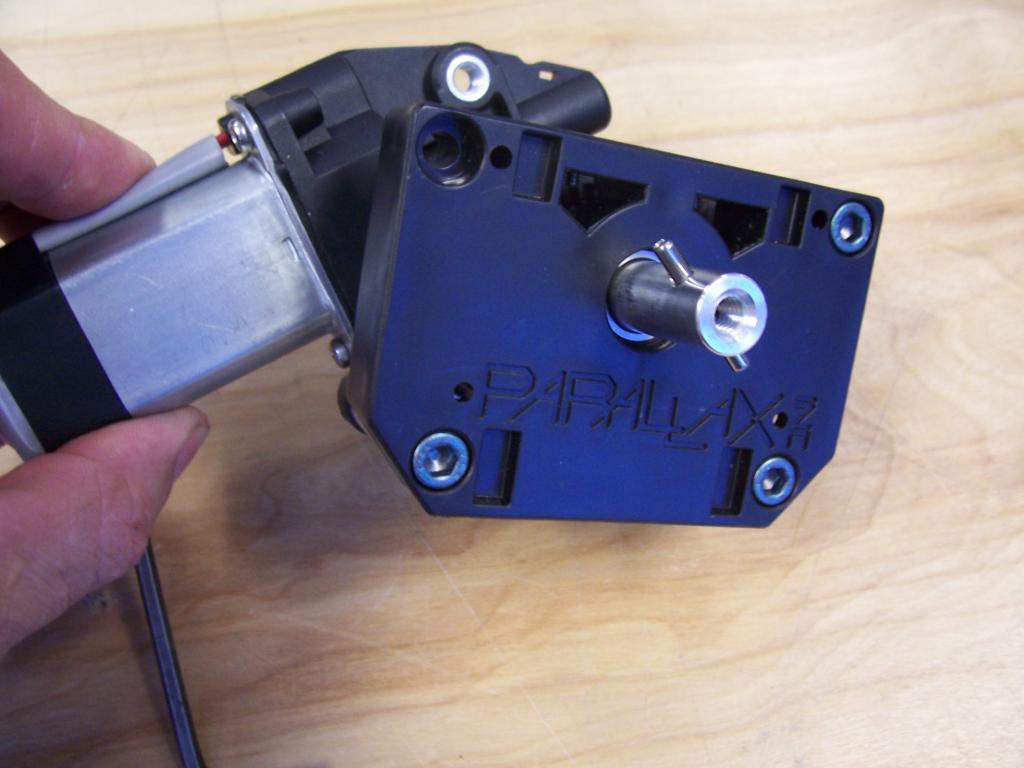

In Parallax, I mean Parallel with this effort, we started to wonder what we could do to make a lower cost, entry-level platform that was functionally similar, but had a lower retail cost.

Hence, we turned to (my personal favorite) HDPE - High Density Poly Ethylene. Apologies to erco in advance...

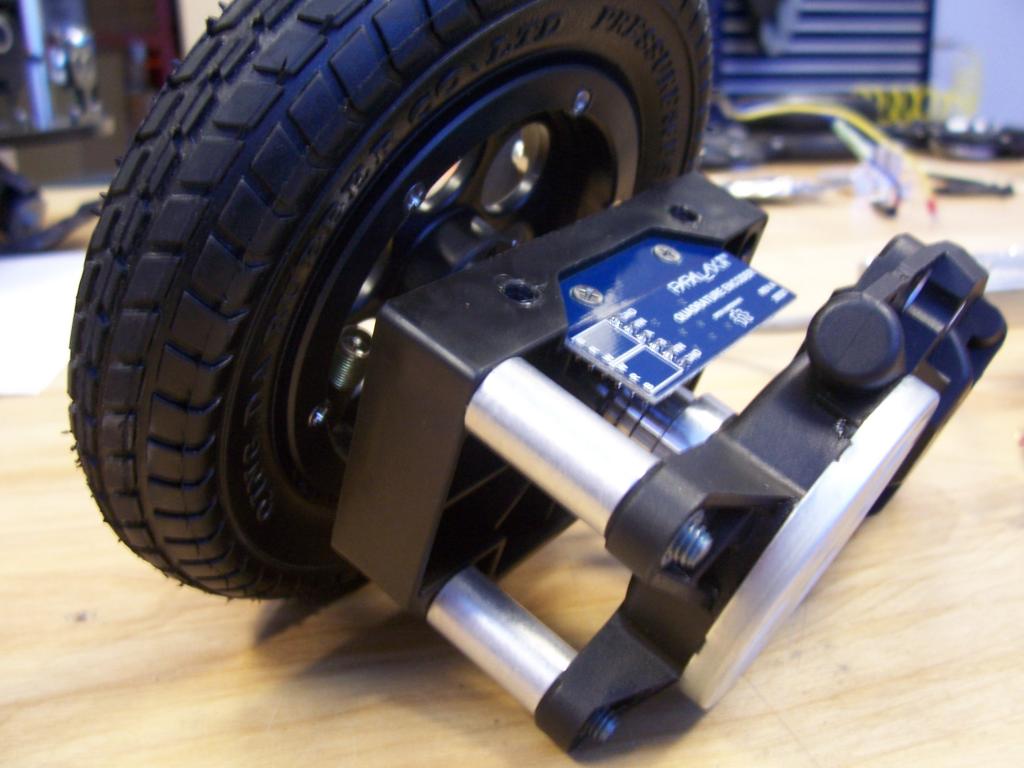

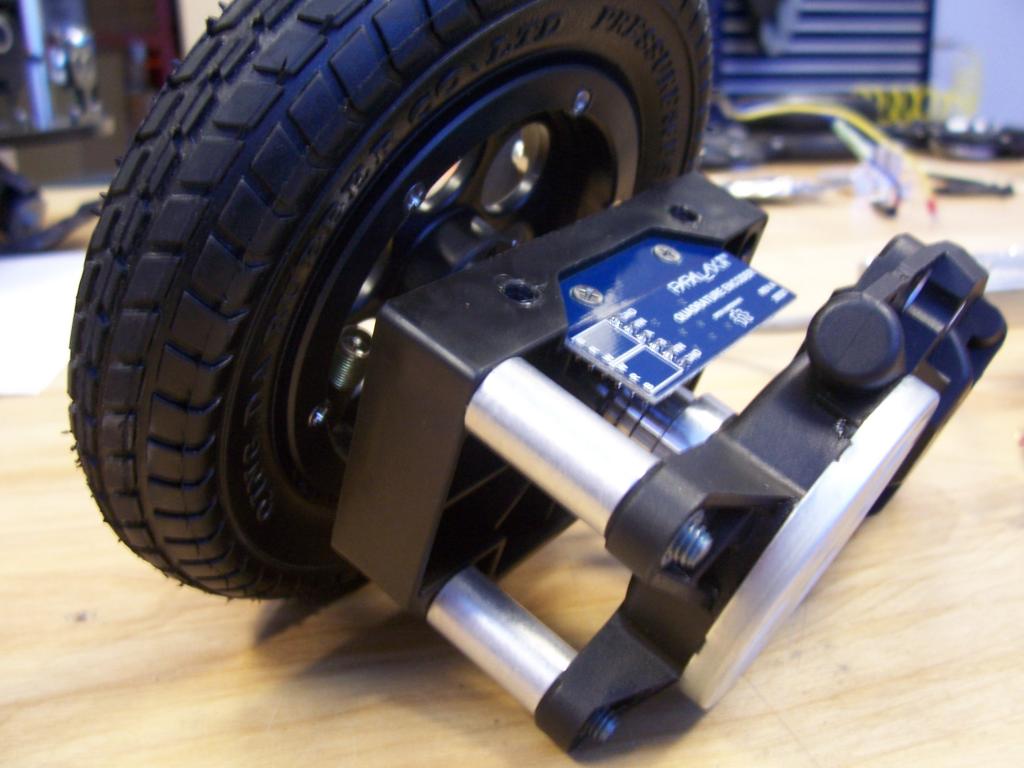

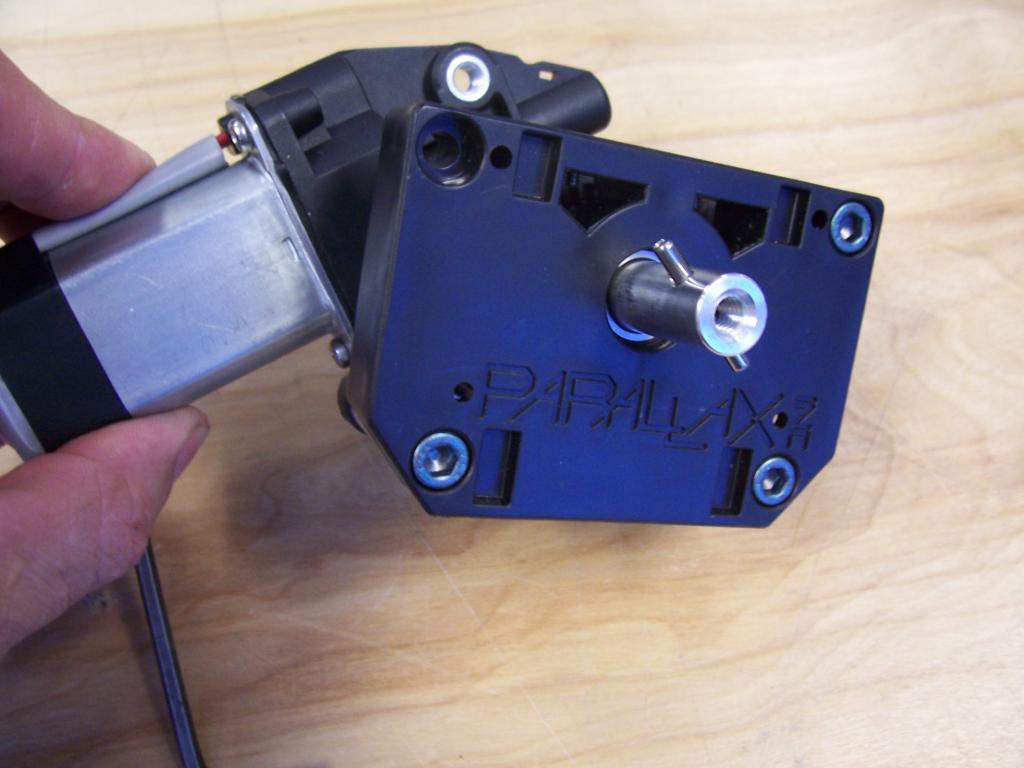

And, this is what the new prototype HDPE drive system looks like

The HDPE Motor Mount Block is accompanied by a split ring HDPE Rim System, as you can see in the pic above.

This is what the Block looks like before you bolt the wheel on...

Yes, it DOES NOT have the same load carrying capacity as the aluminum.

Yes, it IS COMPATIBLE with the same basic Robot Platform and Double Battery Shelf.

Yes, it WILL BE a less expensive kit. (more "entry level" pricing for a "very capable and robust" mobile robotic platform

One disadvantage (at least we thought early on) was that we could not simply tap holes in the rim assembly. This is because the pressure of the tires bearing against the rims would possibly come apart....

But, all that did was give us a reason to install "Lug Nuts" on the outside rim :-)

They're actually not lug nuts, they're acorn nuts but the look is undeniably "Lug-Nutty".

Both of the new kits - the "Motor Mount and Wheel Kit 2" and the "Motor Mount and Wheel Kit 2MP' (MP for "Molded Plastic") will be available RSN (real soon now)...

Final specs to be published soon, but a few specs now wouldn't hurt now:

Both kits use the same drive motors. The speed is about 75-80% of the former system that they replace.

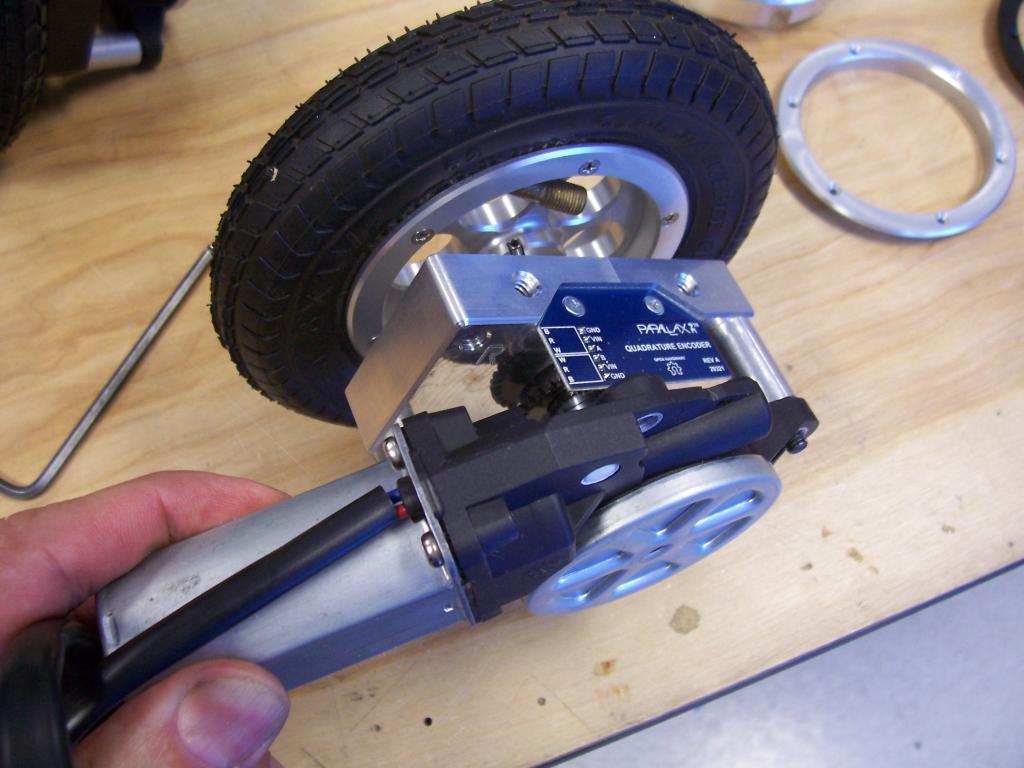

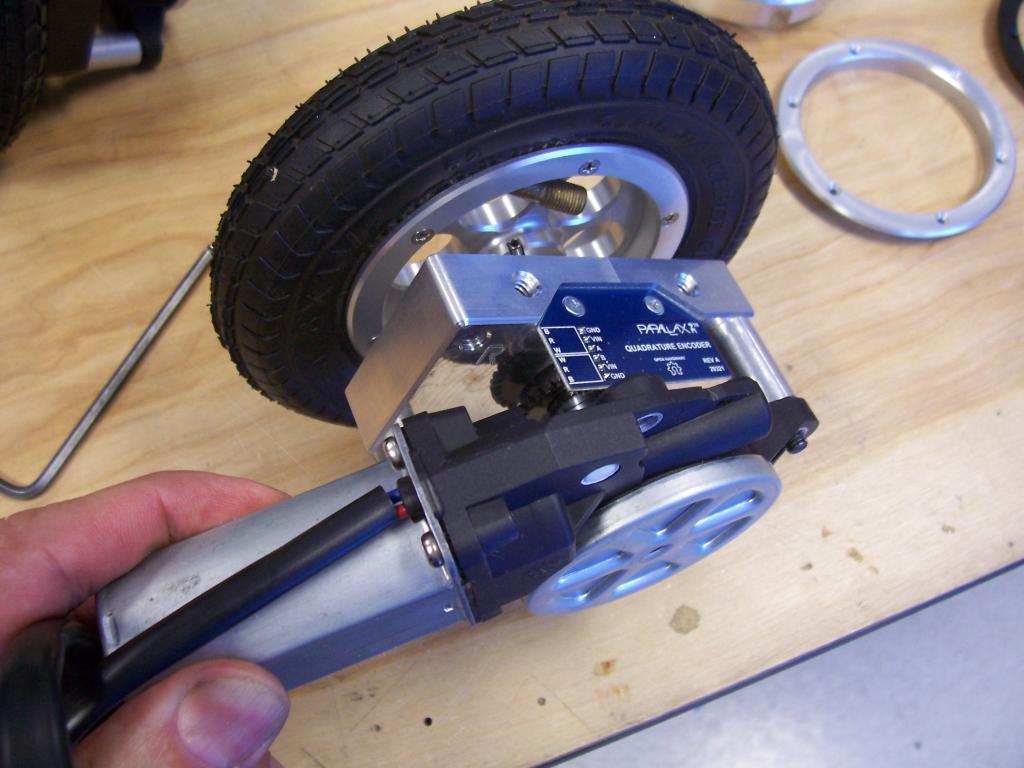

Both Kits use and include the same 29321 Quadrature Encoder Kits, that we've all grown to love..

Plus! These motors tend to exhibit FAR LESS backlash than the prior ones... enabling you to take advantage of the 144 'ticks' on the 29321 encoders!

Oh, and as far as pricing?

Aluminum version should cost about the same as the Old Aluminum Version.

The HDPE Version should cost less.

If I say anything more than that, I'll be in really deep doodoo. :-)

-MattG

So it's no secret that we're re-vamping and upgrading and changing and...and, well, since Ken alluded to "a lower-cost MadeUSA base with molded plastic wheels". .

Here you go :-) this'll give you something to "chew on" over the long weekend...

The original motor drive system was based on some drive motors that were discontinued by the manufacturer. We searched the world, and nearest galaxy's - to no avail - we needed another source - along with that came the necessity for a new Motor Mount and Wheel Kit design.

But along with that, we needed to maintain "upwards" compatibility - at least as much as was economically possible.

So, this is what we had: The "Motor Mount and Wheel Kit"...

It has served us very well over the years.

Now, this is the new Aluminum version with the new motors: Motor configuration is very close to the original, and in fact, mounts with the same size blocks and same hole mounting locations. That is to say that the motor mounts to the block in a similar way, but those holes are in different locations.

The Blocks however, have their mounting holes (that attach the drive assembly to a robot base), in the same locations as the original MMWK.

This is what the new motors look like when mounted to the new Aluminum motor mount blocks. Again, different hole locations for motor to block, but same hole spacing from block to what you choose to mount it to...

Oh, and The Aluminum wheel assembly (split ring hub) remains the same, and accompanies the Aluminum motor mount block system, just like before. This new kit has a "Solid Supplier of Motors" (that are currently in production) - no worries about Rev C for a while.

In Parallax, I mean Parallel with this effort, we started to wonder what we could do to make a lower cost, entry-level platform that was functionally similar, but had a lower retail cost.

Hence, we turned to (my personal favorite) HDPE - High Density Poly Ethylene. Apologies to erco in advance...

And, this is what the new prototype HDPE drive system looks like

The HDPE Motor Mount Block is accompanied by a split ring HDPE Rim System, as you can see in the pic above.

This is what the Block looks like before you bolt the wheel on...

Yes, it DOES NOT have the same load carrying capacity as the aluminum.

Yes, it IS COMPATIBLE with the same basic Robot Platform and Double Battery Shelf.

Yes, it WILL BE a less expensive kit. (more "entry level" pricing for a "very capable and robust" mobile robotic platform

One disadvantage (at least we thought early on) was that we could not simply tap holes in the rim assembly. This is because the pressure of the tires bearing against the rims would possibly come apart....

But, all that did was give us a reason to install "Lug Nuts" on the outside rim :-)

They're actually not lug nuts, they're acorn nuts but the look is undeniably "Lug-Nutty".

Both of the new kits - the "Motor Mount and Wheel Kit 2" and the "Motor Mount and Wheel Kit 2MP' (MP for "Molded Plastic") will be available RSN (real soon now)...

Final specs to be published soon, but a few specs now wouldn't hurt now:

Both kits use the same drive motors. The speed is about 75-80% of the former system that they replace.

Both Kits use and include the same 29321 Quadrature Encoder Kits, that we've all grown to love..

Plus! These motors tend to exhibit FAR LESS backlash than the prior ones... enabling you to take advantage of the 144 'ticks' on the 29321 encoders!

Oh, and as far as pricing?

Aluminum version should cost about the same as the Old Aluminum Version.

The HDPE Version should cost less.

If I say anything more than that, I'll be in really deep doodoo. :-)

-MattG

Comments

After completing some load tests, here are the preliminary results:

The Aluminum version, as expected can carry the same amount of payload as the prior version. As many of you may recall, it actually carried me over a smooth floor, but my 175# test is not what we recommend. The casters tend to really squish down at that weight, so we're usually de-rate the Aluminum versions to probably about 60lbs. That would be payload, not including the weight of the base platform, motors, wheels, mounts and batteries, etc

The HDPE version has been tested up to 60# of payload. At that weight, the wheel hubs do flex more than is desirable- although they didn't break, they were not looking "happy".

@30# there were no issues nor significant flexing noted. We're probably going to de-rate the HDPE MMWK2 to 20# of payload - which, like above, does not include the weight of the base, batteries, plate, etc.

I'm thinking that 20# provides for quite a bit of "add-ons"? What do you think?

Because the cost will be less, it may be a more "classroom-friendly" package.

-MattG

In addition to a less costly two wheel HDPE package... I would greatly appreciate an additional discount for a 4 wheel package.

You said "Ask me about the Lifetime Warranty of the Propeller BOE." Ok... I hate the breadboard for final designs. I know it is fine, but I don't like it...

If I desolder the SIP sockets, do I void my warranty?... any chance of getting the Propeller BOE without the sockets?

I think these new motor mounts will work out well for quite a few robot projects I have planned. Any idea when we may be able to order a preliminary set for testing? I'd like to see how they work first hand.

Also, have you found any foam filled or solid tires that fit on those rims? They way I've used these motors in the past it is very difficult to add air in the tires on the base. I added some short valve extenders I found at the auto parts store which helped a little. If there is a solid or foam filled replacement I'd switch to them on my own robots.

Were you ever able to get a sample of the 6" Colson performa wheels?

http://www.colsoncaster.com/products/productdetails/default.aspx?productid=44

They make great wheels for a robot.

Hi rjo -

In answer to your question about the warranty on the Prop BOE. we'll look to our Fearless Leader, Sir Ken of Prop-alot...

For the full discussion click here.

As far as getting it without the sockets, I'll double check but I don't see why not- we'd have to know ahead of the next production run...I'll check. One? More than one?

-MattG

Answer= "Better than"

Reason = "When Robot tires fall off, you DON'T go head-over-heels over the handlebars.

-Safety Matt

According to our supplier, we should receive our first production mid-late September :-)

No, never did get a sample - I should re-open that request, thanks for the reminder.

Do you need to add air often? They should hold for a very long time. Slow leak, or heavy loads?

No, I haven't as yet, Not sure that would be cost effective - we get these in pretty high volumes.

-MattG

Hello Matt,

Possibly a slow leak. It seems to hold air for a while but I have to top them off a couple times a year or more. Not a big deal if everything is exposed like on the normal Eddie platform but for finished robots it can be very difficult to get to the air valve. Some tubes/tires seem to hold air better than others but I haven't seen many that didn't lose a little air.

That is one of the reasons I prefer those Colson castors. They have been used on robots for years, proven tough, and I never need to add air or check them. It just isn't an issue.

With your machining wizardry I'm sure you could make a hub adapter for the 6" x 1.5" wheels.

Don't get me wrong, I really like the wheel kit you have now. I just wish there was an option for a solid (or foam filled) wheel like the colsons.

Robert

So, I'll ask everybody: How much payload (over and above the weight of the unit itself) do you all put on your robot platforms?

What's the *norm*? 1 lb? 5 lbs? 20 lbs???

and, more how much would you expect a robot platform like this to carry?

Give us a target, so-to-speak.

-MattG

Thank you very much for the effort...just 2 I'm afraid. Either the Prop-BOE or the Activity Board would be fine. I'm just talking about the sockets around the bread board. The three pin headers are fine.

You might want to poll the forum on whether Parallax should generally offer breadboard-less options on its boards... it would save you a few pennies on each board and it might make the boards

more project friendly, since the area is perfect for adding prototype pcbs.

Hello Matt,

I have one design I am trying to standardize on that would add about 50lbs. Maybe up to 80lbs with all the options. I also have another platform that would weight a lot less. I have a couple larger promotional show robots but those usually have wheelchair motors and would be more in the 120lbs to 175lbs range. Maybe a bit too much for these.

So far the capacity hasn't been a problem. It is the maintenance required. Tires that need air will always need air. Just like checking the tires on the car or bikes. Using those colsons I recommended can turn that into no maintenance. I have some robots with wheels like these that are over 25 years old and the wheels are still fine. I just don't have to worry about them. Given enough time and rough surfaces the wheels can wear but I am sure that the rubber on a tube type tire would dry out and start cracking and need to be replaced well before the colsons would. The other advantage is that these use a grey non-marring tread that won't (shouldn't) leave marks on floors. The black rubber tires an mark up floors.

I suppose some people may prefer the tube type tires and that's fine. It would just be nice to explore the option of the other wheels since I'm sure there are others like me that would prefer them in many cases.

Robert