MAX6675 For Reflow Oven controller

Ok ,

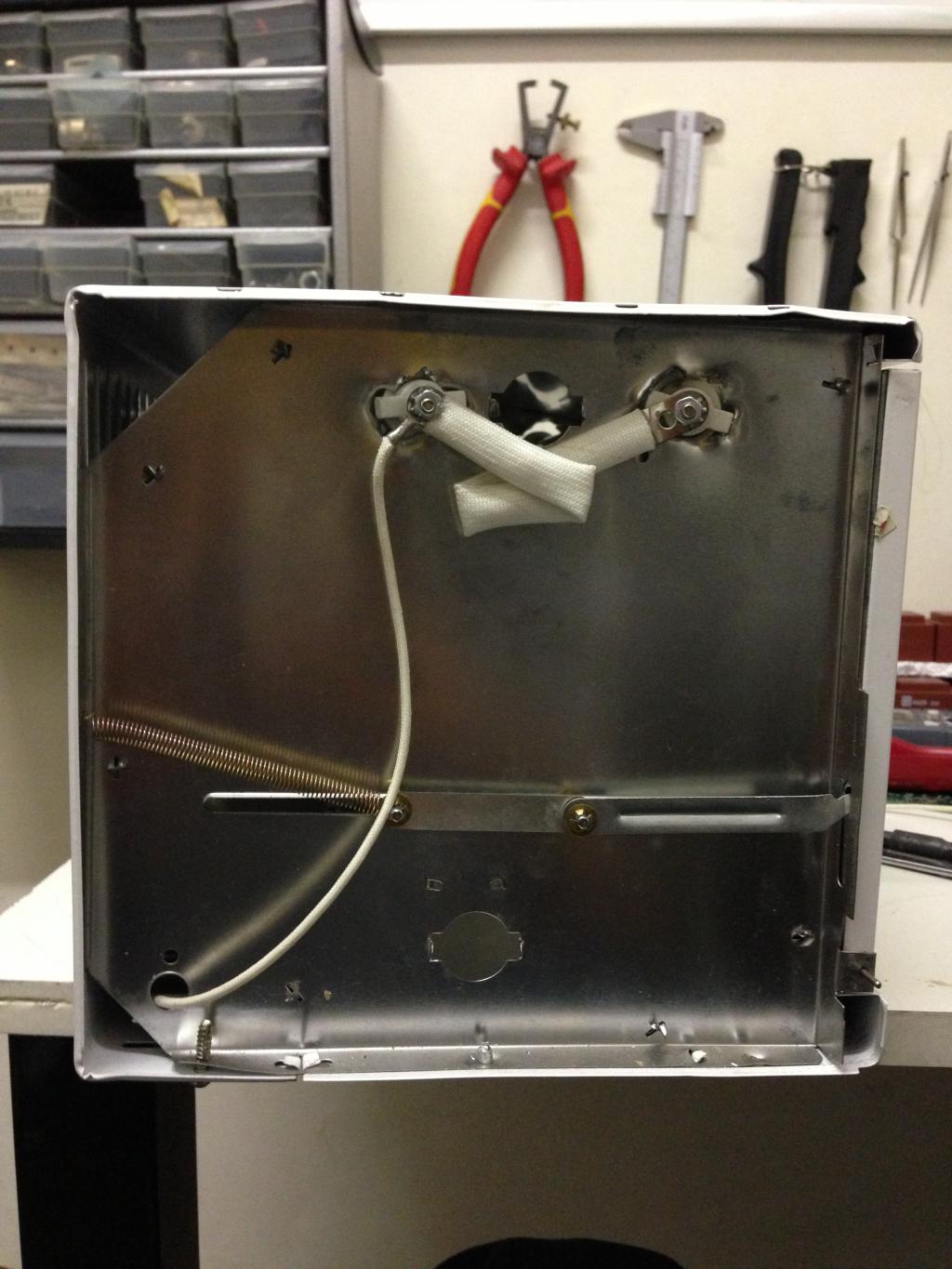

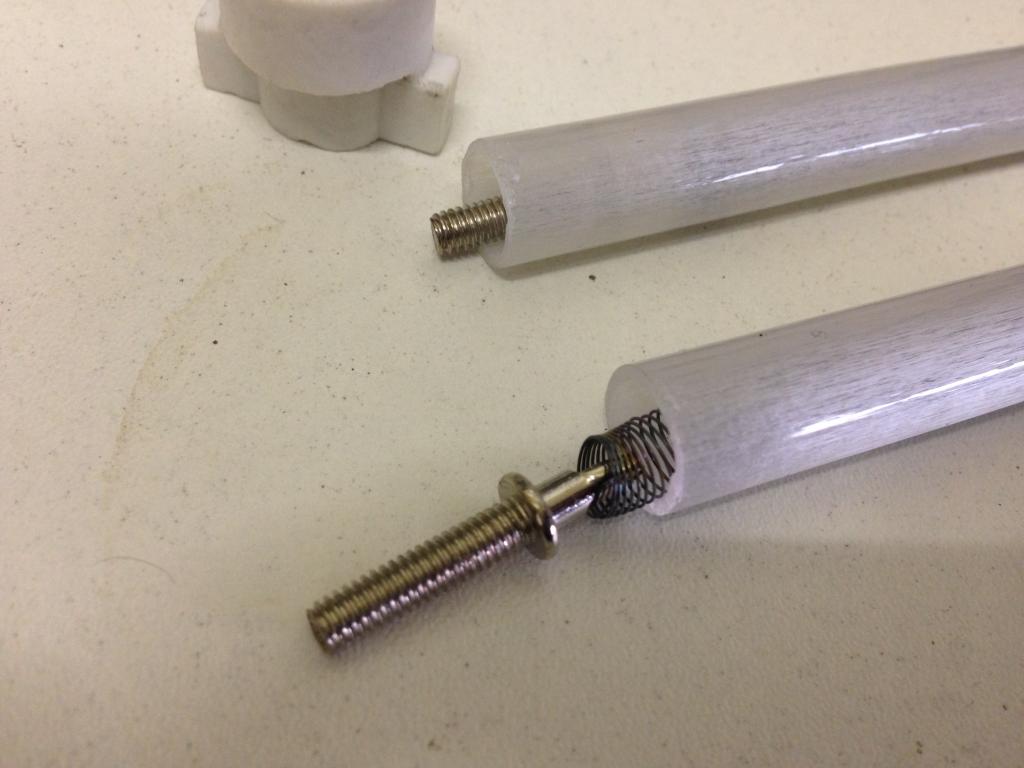

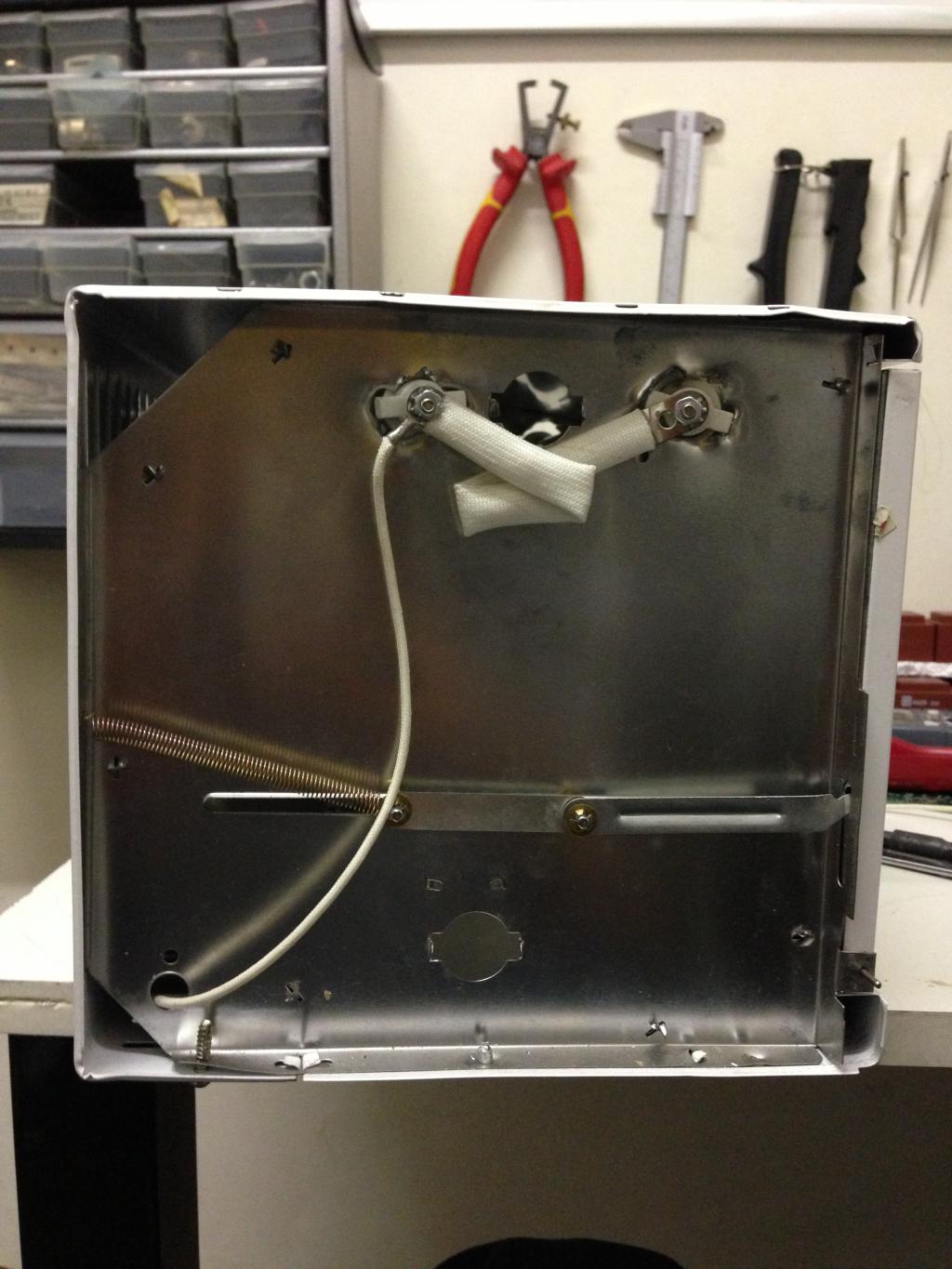

SO I am trying to build a small reflow oven controller, already have the oven ( a small 9liter model ) modified bringin both heating elements to the top , also a solid state relay to turn it on/off . ill figure pwm will have to do that later .

But for the moment I cant get to seem to get any temp readings out of the max 6675 ,

This is my second one , The first one , i think i blew it up by putting more then 5 volts acoss it by accident , but now the second ( these are not the cheapest ) is also not sowing me some love here

Anyone mind sharing a pice of code , I have tryied modifinig the one found in the obex(Mike Lord) that usualy works with a tv , but I need it to work on terminal to start with , after i got a 20X4 lcd already hooked and working . still no luck with it .

code used is below ,

Any help in the right direction would be greatly appriciated :P:thanks

Previeuw

SO I am trying to build a small reflow oven controller, already have the oven ( a small 9liter model ) modified bringin both heating elements to the top , also a solid state relay to turn it on/off . ill figure pwm will have to do that later .

But for the moment I cant get to seem to get any temp readings out of the max 6675 ,

This is my second one , The first one , i think i blew it up by putting more then 5 volts acoss it by accident , but now the second ( these are not the cheapest ) is also not sowing me some love here

Anyone mind sharing a pice of code , I have tryied modifinig the one found in the obex(Mike Lord) that usualy works with a tv , but I need it to work on terminal to start with , after i got a 20X4 lcd already hooked and working . still no luck with it .

code used is below ,

CON

_CLKMODE = XTAL1 + PLL16X

_XINFREQ = 5_000_000

SCK = 0

CS = 1

So = 18

TempScale = 0 '1 is Farienheight 0 is Centegrade

RS = 11 ' 1

RW = 10 ' 2

E = 9 ' 3

DBLow = 12 ' 0

DBHigh = 15

' ASCII codes.

CR = 13

LF = 10

PSTClearScreen = 16

Var

Long TempIn

OBJ

Max6675 : "Max6675_K_thermoCouple"

pst : "parallax serial terminal"

LCD : "LCD_20x4"

'====================================================================================

PUB _Start | TimeCnt_10Hz, DisplayTime , ElapsedCnt , index , AddrVar

'====================================================================================

Initialize

LCD.RawSetPos( $00 ) ' "first" line

LCD.RawWriteStr( string("reading sendor") )

waitcnt(clkfreq *2 + cnt)

repeat

' !Outa[LedPin]

Max6675.ReadTemp(So, CS, SCK , TempScale , @TempIn )

pst.Str(String("Measured Temperture in Celsius = "))

pst.dec( Tempin)

pst.Str(String(" ",13))

'LCD.RawSetPos( $40 ) ' "second" line

' LCD.RawWriteStr( string(Tempin) )

waitcnt(clkfreq *2 + cnt) 'dont scan too fast or the conversion will not run

'====================================================================================

Pub Initialize

'====================================================================================

'Start cogs

pst.start(115_200)

waitcnt(clkfreq + cnt)

pst.str(string(13,"MAX6675 ThermoCouple Demo.",13))

LCD.usDelay( 5_0 ) ' time enough to switch to PST

pst.str(string(13,"Start LCD Driver.",13))

LCD.Init( E, RS, RW, DBHigh, DBLow )

LCD.Clear

LCD.usDelay( 2_000_000 )

{

''***************************************

''* MAX675 v1.1 *

''* Author: Mike Lord *

''* Copyright (c) Mike Lord *

''* Mike@electronicdesignservice.com *

''* 650-219-6467 *

''* See end of file for terms of use. *

''***************************************

' v1.0 - 01 Jul7 2011 - original version

This is written as a spin driver for the max6675 K type thermocouple chip.

┌─────────────────────────────────────┬────────────────┬─────────────────────┬───────────────┐

│ MAX6675 driver │ PG | (C) 2011 | July 20 2011 |

├─────────────────────────────────────┴────────────────┴─────────────────────┴───────────────┤

│ │

│ A driver for the MAX6675 K Type theromcouple chip │

| |

| See end of file for terms of use |

└────────────────────────────────────────────────────────────────────────────────────────────┘

SCHEMATIC

┌────┐

Gnd 1 │ │ 8 Nc

T+ 2 │MAX │ 7 Sd

T- 3 │6675 │ 6 Cs

Vcc 4 │ │ 5 Sck

└──────┘

}

CON

var long stack1[20]

long CogNr,InBit,Value

obj

Tv : "Mirror_TV_Text"

'==================================================================

Pub ReadTemp(SD, CS, SCK, TempScale , TempertureIn_Addr ) | Index , AddrVar

'==================================================================

' SD, CS, SCK are the pin numbers of the propeller connected to the max6675

'TempScale = 1 '1 is Farienheight 0 is Centegrade

dira[Cs] := 1

dira[SCK] := 1

dira[Sd] := 0

Outa[Cs] := 1 'Make sure chip select is high

Outa[SCK] := 0 'make sure Sck is low as initial value

Outa[Cs] := 0 'Now take Chip select low to shart shift out of data

'Tv.out($0A) 'X position follows

'Tv.out( 1 + index )

'Tv.out($0B) 'Y position follows

'Tv.out( 3 )

'Repeat Index from 0 to 15

Waitcnt(clkfreq /10_000 + cnt)

Outa[SCK] := 1

Waitcnt(clkfreq /10_000 + cnt)

Outa[SCK] := 0 'Data is now ready to be read

Long[@TempertureIn_Addr] := 67 'Ina[Sd]

'Tv.hex( @TempertureIn_Addr, 4 )

' Tv.Str(String("-"))

'Tv.dec(Long[@TempertureIn_Addr])

'Tv.Str(String(" "))

Outa[Cs] := 1 'Make sure chip select is high

Outa[SCK] := 0 'make sure Sck is low as initial value

' Tv.out($0D)

'Tv.Str(String("after routine"))

return

{

PUB SHIFTIN (Dpin, Cpin, Mode, Bits) : Value | InBit

{{

Shift data in, master clock, for mode use BS2#MSBPRE, #MSBPOST, #LSBPRE, #LSBPOST

Clock rate is ~16Kbps. Use at 80MHz only is recommended.

X := BS2.SHIFTIN(5,6,BS2#MSBPOST,8)

}}

dira[Dpin]~ ' Set data pin to input

outa[Cpin]:=0 ' Set clock low

dira[Cpin]~~ ' Set clock pin to output

If Mode == MSBPRE ' Mode - MSB, before clock

Value:=0

REPEAT Bits ' for number of bits

InBit:= ina[Dpin] ' get bit value

Value := (Value << 1) + InBit ' Add to value shifted by position

!outa[Cpin] ' cycle clock

!outa[Cpin]

waitcnt(1000 + cnt) ' time delay

elseif Mode == MSBPOST ' Mode - MSB, after clock

Value:=0

REPEAT Bits ' for number of bits

!outa[Cpin] ' cycle clock

!outa[Cpin]

InBit:= ina[Dpin] ' get bit value

Value := (Value << 1) + InBit ' Add to value shifted by position

waitcnt(1000 + cnt) ' time delay

elseif Mode == LSBPOST ' Mode - LSB, after clock

Value:=0

REPEAT Bits ' for number of bits

!outa[Cpin] ' cycle clock

!outa[Cpin]

InBit:= ina[Dpin] ' get bit value

Value := (InBit << (bits-1)) + (Value >> 1) ' Add to value shifted by position

waitcnt(1000 + cnt) ' time delay

elseif Mode == LSBPRE ' Mode - LSB, before clock

Value:=0

REPEAT Bits ' for number of bits

InBit:= ina[Dpin] ' get bit value

Value := (Value >> 1) + (InBit << (bits-1)) ' Add to value shifted by position

!outa[Cpin] ' cycle clock

!outa[Cpin]

waitcnt(1000 + cnt) ' time delay

elseif Mode == OnClock

Value:=0

REPEAT Bits ' for number of bits

!outa[Cpin] ' cycle clock

waitcnt(500 + cnt) ' get bit value

InBit:= ina[Dpin] ' time delay

Value := (Value << 1) + InBit ' Add to value shifted by position

!outa[Cpin]

waitcnt(500 + cnt)

Any help in the right direction would be greatly appriciated :P:thanks

Previeuw

Comments

I took a look at the OBEX listing. There are two drivers there. One is the suspect in-line object "MAX6675_K_ThermoCouple" as you have it above, and the other is "MAX6675_K_ThermoCouple_Cog", which runs in its own cog, and seems to be polished, and is is the one that should really read and return a value from the sensor.

the shifting in routine was never my strong point ,

@ JonnyMac , Thanks for the headsup with the code ,

Ive try implementing it , looks to be going in the good direction here , but dont understand it completly ,

The values comming out supose to be are not like the 0.25 range I suspect it to be

the return temp * 25 , i dont understand if its a 0.25 resolution based on 12 bits out of 16 bits , we suppose to shift to the right bits first(D-14-D3).

Going to need in in a value so I can make the rest of the calculations

OBJ Max6675 : "Termomax6675.spin" '"Max6675_K_thermoCouple" pst : "parallax serial terminal" LCD : "LCD_20x4" '==================================================================================== PUB _Start | TimeCnt_10Hz, DisplayTime , ElapsedCnt , index , AddrVar '==================================================================================== Initialize LCD.RawSetPos( $00 ) ' "first" line LCD.RawWriteStr( string("reading sendor") ) waitcnt(clkfreq *2 + cnt) repeat TempReading := Max6675.tc pst.Str(String("Measured Temperture in Celsius = ")) pst.dec (TempReading) pst.Str(String(" ",13)) 'LCD.RawSetPos( $40 ) ' "second" line ' LCD.RawWriteStr( string(Tempin) ) waitcnt(clkfreq *2 + cnt) 'dont scan too fast or the conversion will not run '==================================================================================== Pub Initialize '==================================================================================== 'Start cogs pst.start(115_200) waitcnt(clkfreq + cnt) pst.str(string(13,"MAX6675 ThermoCouple Demo.",13)) LCD.usDelay( 5_0 ) ' time enough to switch to PST pst.str(string(13,"Start LCD Driver.",13)) LCD.Init( E, RS, RW, DBHigh, DBLow ) LCD.Clear LCD.usDelay( 2_000_000 ) Max6675.start(CS, SCK, So)[HTML]

MAX6675 ThermoCouple Demo.

Start LCD Driver.

Measured Temperture in Celsius = 5650

Measured Temperture in Celsius = 5600

Measured Temperture in Celsius = 5700

Measured Temperture in Celsius = 5600

Measured Temperture in Celsius = 5650

Measured Temperture in Celsius = 5700

Measured Temperture in Celsius = 5750

Measured Temperture in Celsius = 5750

Measured Temperture in Celsius = 5700

Measured Temperture in Celsius = 5650

Measured Temperture in Celsius = 5750

Measured Temperture in Celsius = 5650

Measured Temperture in Celsius = 5750

Measured Temperture in Celsius = 5600

Measured Temperture in Celsius = 5700

Measured Temperture in Celsius = 5750

Measured Temperture in Celsius = 5650

Measured Temperture in Celsius = 5750

Measured Temperture in Celsius = 5700

Measured Temperture in Celsius = 5600

Measured Temperture in Celsius = 5800

Measured Temperture in Celsius = 5750

Measured Temperture in Celsius = 5700

Measured Temperture in Celsius = 5750 [/HTML]

And I used JonnyMac code below (see OBJ Max6675 : "Termomax6675.spin" )

Bye the way , anyone know of a drop in 1 pin pwm to controll the solid state relay power% with a value

Many thanks again in advanve

If i change the reading part like below

temp := read if (hassensor == true) return temp else return -1Wich give me a result that resembles the temperture in C more corretly , but im not sure im right about that , cause its supose to be a 0.25 resulution , and 225/4 = 56.C wich doesnt make sense for the room tempeture its in

[HTML]Measured Temperture in Celsius = 224

Measured Temperture in Celsius = 224

Measured Temperture in Celsius = 218

Measured Temperture in Celsius = 226

Measured Temperture in Celsius = 224

Measured Temperture in Celsius = 224

Measured Temperture in Celsius = 224

Measured Temperture in Celsius = 226

Measured Temperture in Celsius = 222

Measured Temperture in Celsius = 224

Measured Temperture in Celsius = 224

MMeasured Temperture in Celsius = 226

[/HTML]

I find 0.25C units inconvenient -- especially dealing with integer values. Multiplying by 25 is the same as multiplying by 0.25 and then by 100; the result is that we get 0.01 degree units; much easier to deal with and read in a display. You should see something like 2275 which would be 22.75 degrees C.

@WBA

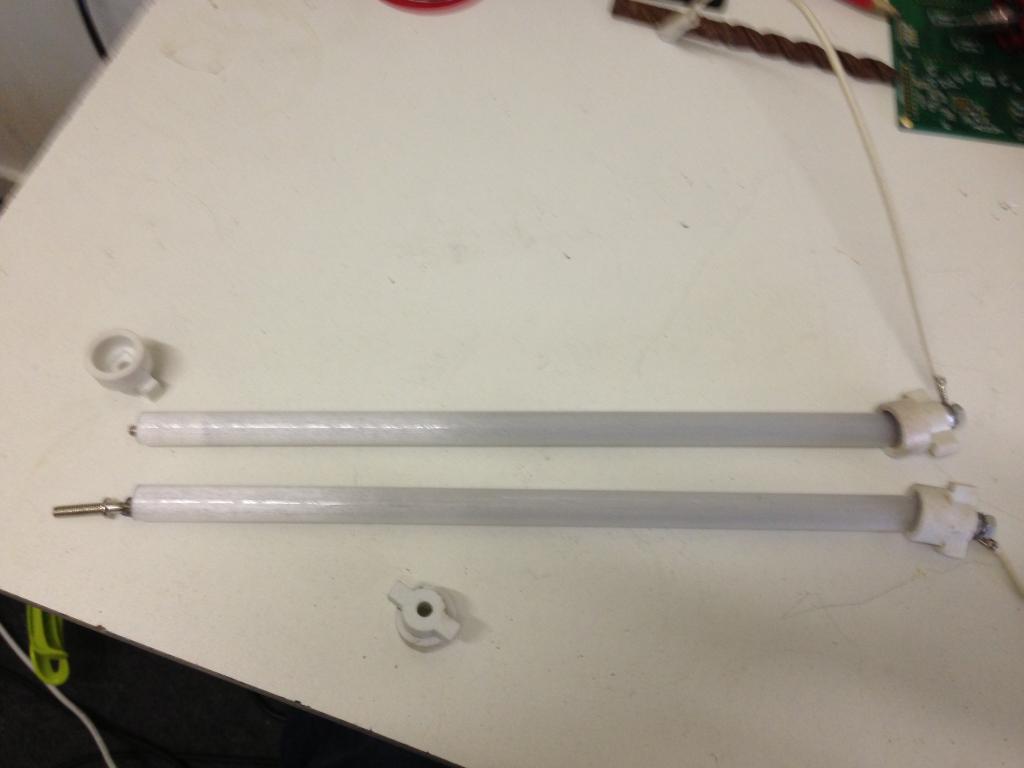

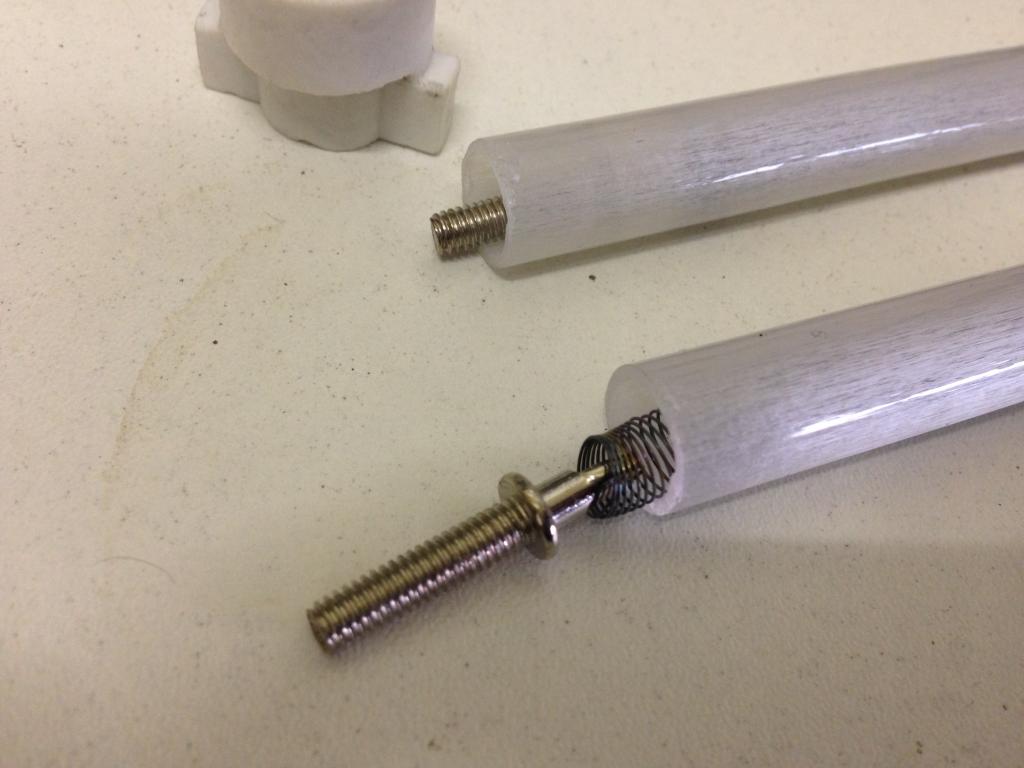

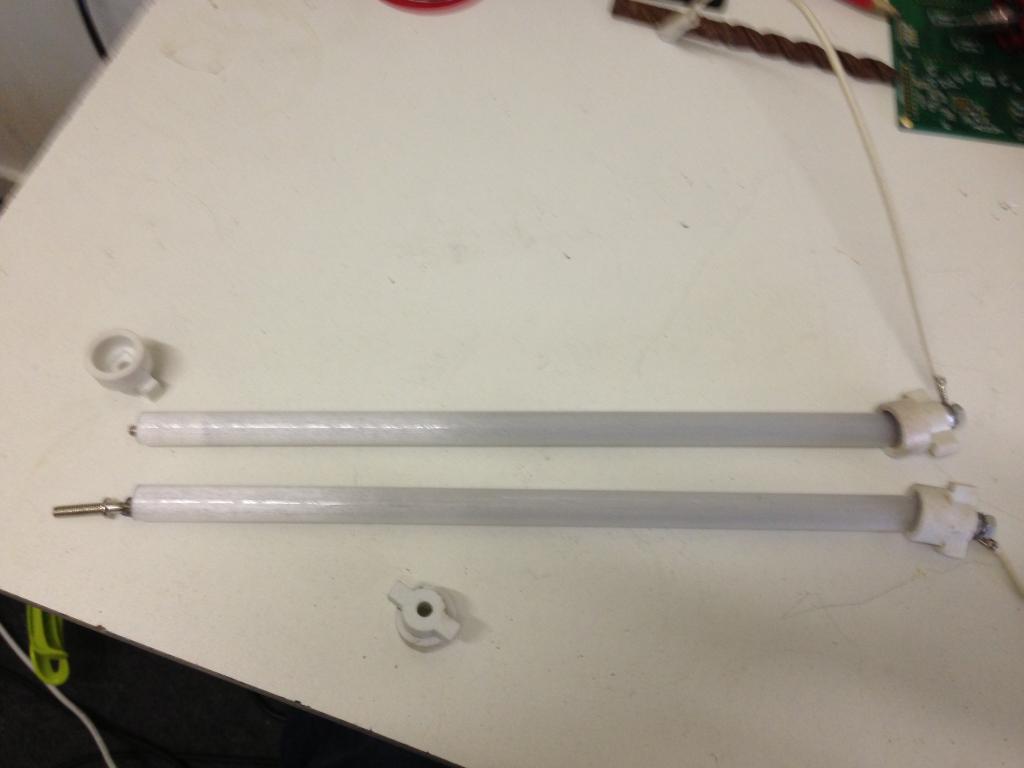

I moved them both to the top to try to get a better heat spread on the pcb board , probably going to solder only on 1 side anyway , so think the one below is kinda useless to heat up the pcb from below if your not planning on double sided pcbś . I think I read it somewhere that it was better to move them both to the top , but cant recall where I read that , But seems to make some sens to mee , so I did it , When the temp reading and callibrating starts ill see if it does make sense or not . Ill post updates about it later

Havent seen a drop in easy to use Reflow Controller , based on the propeller , but I know allot must have done it cause it cant be easier with the Prop dropping in the right objects and building a top level controller for it , So im planning to release the code , schematic , and parts used to build it , so anybody can build it based on a propeller

Max6675+DS1820(just for ref) + 20*4 Char LCD + 10A SSR + plus a few buttons I think .

pri control_ssr(zcpin, ssrpin, p_level) | level ' launch with cognew '' Control SSR based on value (0 to 100) at address in p_level '' -- zcpin is zero-cross input from AC '' -- ssprin is control output to SSR dira[zcpin] := 0 ' force to input outa[ssrpin] := 1 ' start off dira[ssrpin] := 0 repeat level := 0 #> long[p_level] <# 100 ' keep in legal bounds if (level == 0) outa[ssrpin] := 0 ' off else outa[ssrpin] := 1 ' on repeat level waitpne(1 << zcpin, 1 << zcpin, 0) ' wait for zero-cross waitpeq(1 << zcpin, 1 << zcpin, 0) outa[ssrpin] := 0 ' off repeat (100 - level) waitpne(1 << zcpin, 1 << zcpin, 0) waitpeq(1 << zcpin, 1 << zcpin, 0)I've attached a schematic for zero-cross detection; this is tested -- I use it in an AC lighting controller. The 15K resistors at 2W each.

Here's an example of a commerical product I programmed and used this object in:

-- http://www.cameraturret.com/genesis.htm

True story: this controller was being used on a film shoot in some remote desert region and during a shot in a cave, a rock fell onto the device and broke the LCD. This could have been disastrous, but wasn't, because we had made such a simple interface with the UP, DN, LF, RT, ENT, and ESC buttons -- the operator was able to remember the button sequences and they got the shots they needed!

One of the useful methods in this object is called rjdec() for right-justified decimal values. This routine will get a lot of use displaying temperature and other values on your reflow controller.

About the LCD driver , Ill look into it , i know its indeed a thing always to get the value in the right format to get it display endso , I struggled with it allot also but I managed to get it working , going to look tru yours to see what more I can learn about it.

I did manage to get both the Max6675 and the DS1820 To display the reading on the LCD and in the Serial terminal , ( can comment out one of them if not used )

And overall I see I have a difference of about 7degrees between them , the max6675 reading the highest . but dont think thats going to be that big of a problem (add an offset i think ) also I am going to dived the readings by 100 still to get only hole degrees , cause that much precishon I probably cant controll anyway. so not needed and easyer i think to manage

Code used

CON _CLKMODE = XTAL1 + PLL16X _XINFREQ = 5_000_000 DS1820_D_PIN = 17 SCK = 0 ' Max6675 Pin CS = 1 ' Max6675 Pin So = 18 ' Max6675 Pin TempScale = 0 '1 is Farienheight 0 is Centegrade RS = 11 ' LCD Control Pins RW = 10 ' LCD Control Pins E = 9 ' LCD Control Pins DBLow = 12 ' LCD Data Pins DBHigh = 15 ' LCD Data Pins ' ASCII codes. CR = 13 LF = 10 PSTClearScreen = 16 ' One Wire Values . CVRT_TEMP = $44 SKIP_ROM = $CC RD_SPAD = $BE Var Long TempReading1, TempReading2 OBJ ow : "jm_1-wire" Max6675 : "jm_max6675.spin" '"Max6675_K_thermoCouple" pst : "parallax serial terminal" LCD : "LCD_20x4" num : "simple_numbers" f : "Float32" fp : "FloatString" '==================================================================================== PUB _Start | TimeCnt_10Hz, DisplayTime , ElapsedCnt , index , AddrVar '==================================================================================== Initialize LCD.RawSetPos( $40 ) ' "first" line LCD.RawWriteStr( string("Max6675:") ) LCD.RawSetPos( $14 ) {set lcd position} LCD.PrintStr( String("DS1820 :")) waitcnt(clkfreq *2 + cnt) repeat Get_Max6675_Reading Get_DS1820_Reading waitcnt(clkfreq + cnt) 'dont scan too fast or the conversion will not run '==================================================================================== Pub Initialize | status '==================================================================================== 'waitcnt(clkfreq*3 + cnt) 'Give time to open terminal if not auto pst.start(115_200) 'Start Debug Serial Terminal pst.str(string(13,"Serial Terminal : Ready.",13)) 'Lets us know the driver is working waitcnt(clkfreq + cnt) pst.str(string(13,"Start LCD Driver.",13)) 'Start 20x4 Char LCD Driver LCD.Init( E, RS, RW, DBHigh, DBLow ) LCD.Clear LCD.usDelay( 2_000_000 ) LCD.RawSetPos( $00 ) ' "first" line LCD.RawWriteStr( string("LCD Started : Succes") ) 'Lets us know the driver is working waitcnt(clkfreq *2+ cnt) LCD.Clear 'Clear Back the screen Max6675.start(CS, SCK, So) 'Ini Max6675 ow.init(DS1820_D_PIN) 'Ini DS1820 Temp Sensor ( Used as reference ) '==================================================================================== PUB Get_Max6675_Reading '==================================================================================== TempReading1 := Max6675.tc01 'Get reading from MAX6675 pst.Str(String("Max6675 Temperture in Celsius = ")) 'Display in terminal pst.dec (TempReading1) 'Display in terminal pst.Str(String(" ",13)) 'Display in terminal LCD.RawSetPos( $48 ) 'set lcd position LCD.PrintStr(num.dec(TempReading1)) 'Display on LCD '==================================================================================== PUB Get_DS1820_Reading '==================================================================================== TempReading2 := readtc 'Get reading from DS1820 sensor pst.Str(String("DS1820 Temperture in Celsius = ")) 'Display in terminal pst.dec (TempReading2) 'Display in terminal pst.Str(String(" ",13)) 'Display in terminal LCD.RawSetPos( $1C ) 'set lcd position LCD.PrintStr(num.dec(TempReading2)) 'Display on LCD '==================================================================================== pub readtc | tc '==================================================================================== '' Reads temperature from DS1820 '' -- returns degrees C in 0.1 degree units ow.reset ow.write(SKIP_ROM) ow.write(CVRT_TEMP) repeat ' let conversion finish tc := ow.rdbit until (tc == 1) ow.reset ow.write(SKIP_ROM) ow.write(RD_SPAD) tc := ow.read ' lsb of temp tc |= ow.read << 8 ' msb of temp ow.reset tc := ~~tc * 5 ' extend sign, 0.1° units return tcAttached the complete Spin.zip folder so it can be a drop in , Just change the pins accordinglyMAX6675+DS1820_LCD_20*4.zip

So that part worked out pretty fine , reading the temp , think we can call the title of the post solved for that

Reflow still in the making

About the SSR . about now is the time that I start diging into how to run the oven at say 50%. I didnt dig into that yet ,

I did have a pice of code somewhere to pwm a led , so i was thinking of using modifing it somehow to get the relay at different power % controlled by a value , so I can controll it easly . .

Your explination of a triac working got me thinking again , ( I kinda avoided the triac always to understand it completly )

anyway , I do have experiance with a S202S02F Solid state relay

wich is a zero cross relay , and uses a smal ciruit (460ohm resistor + transistor and a diode ) to connect it to the propeller , But like the zerro crossing I had in mind I cant controll it that way , only controled it on/off before , wel that was wat i was thinking at least , propbablt wrong ,

Thats why i bought a Z240D10-17 - SSR, 10A that is direct switching , so I can toggle it directly , to controll it with say pwm , well that was my thinking , got to find that out still, the propeller does turn on /off , if i toggle the pin slowly, dont know about pwm yet. But your mentioning of AC and DC got me thinking again , Guess i will find out soon. Its just a wire that gets heated by pasing the power , I it was a different kind of divice i would be a bigger problem i think .

ill be working on it tonight and comming days to try to get this working , got some board im realy hopin that I can reflow in the future

The buttons design looks sweet , that means saving up pins to do other things , I bet that will com in handy many times in the future , Wil be testing that out i think . But I was thinking of using less buttons as possible , ( if is hady to work with only 2 buttons ) , probably going to use 1 reflow setting ( dont know how to call it , the time/temp that it needs to perform ) so I will program those hard in the program , and use the buttons to start /stop/ pause the program ,

Well lets just say , ill work with whatever works best

I rule!

Did you see that the updated version of my MAX6675 driver has a method called tc() that returns whole degrees? It rounds up based on the lower two bits.

With 50Hz line frequency you're going to have a 10ms (duration of AC half-cycle) granularity with your timing. What's working for you is the thermal inertia of the heating element. You might do something as simple as this -- crude, but with feedback should give you the control you want. As with the other code, this runs in its own cog.

pri ssr_control(ssrpin, p_level) | level ' launch with cognew outa[ssrpin] := 0 ' set to output dira[ssrpin] := 1 repeat level := 0 #> long[p_level] <# 100 ' get level, keep legal if (level > 0) outa[ssrpin] := 1 ' activate SSR waitcnt(cnt + (level * (clkfreq / 100))) ' hold for on timing if (level < 100) outa[ssrpin] := 0 ' de-activate SSR waitcnt(cnt + (100 - level) * (clkfreq / 100)) ' hold for off timingIn my experience "few buttons as possible" always means trickier code, and trickier product. While you don't have to implement the full 6-button interface I tend to use (there is even a patent in my name for a Toro irrigation controller that uses that interface), it does make things easier for the user. My object supports up to six buttons; you don't have to use them all (that is why there is a mask parameter).

That said, it's very easy to create a simple, little-or-no-training-required interface with six buttons. In my projects I use the LF and RT buttons to move between fields. I use UP and DN to change values in a field, ENTER to accept the new value, ESC to bail out without changing what was originally in the fields. Some years ago I coded a commercial HVAC controller using this code and it was a hit. Think about it; the cost of a few more buttons will not break the bank, and could save you hours of coding trying to do everything with just two buttons.

@Jonnymac , thanks again

I am pretty sure im going to implement the buttons interface , thats just to cool to not use , saving pins always good ,

just dont know it it will be with the reflow now, cause

I have a set of 4 buttons hardwired on the pcb already that I will be using , ( just so i dont have to go discover anything ) button = pin works fine , wont be needing the spare pins for now :P usualy use a monolicit lcd driven by 4 hc595 , so there I only use 3 pins but for 4 digits ,

thats why i have a different connection for the buttons on the pcb im using , I think those character lcd with the blue backlight like I have tend to give a product a chinees look , like aftermarket , thats why i prefeur the other ones while R&D for a new controller , Nothing wrong with it , just my thinking where I sell my controllers (dont take it personal , cause it aint

After been soldering allot latly I thouth now is the time to make that simple reflow controller to get the job speeded up , so ill be working to get it working , with just start stop tru terminal for now , just to get the reflowing job done :P

after that ill try to make it as user frendly as possible and building an interface with the buttons and a menu to set the variables needed , gotta find some time for that soon ,

and was hoping to get it working at least so I can use it to reflow a few pcb soon , (they are in production now )

Still need to get myself some stencils for the pcb to get the best result i think

But at the moment im finding out exactly around what temp the paste starts to evaporate , and how long I should keep it soaking there , and where the paste reflows and how long reflow gives the best result , ( the past datasheet only says 180c solder )

Was kinda bussy but manage to get it working , off course it still needs allot of tweaking but I managed to get some test runs with some old pcb that I have

done some runs with some tru hole components just to see what it does also , maybe that wil work :P hihhi

The pcb im plannin on are all smd so that has to be no problem , hopin to do 2 x 70*90mm boards at a time

Some pics

Code used

CON _CLKMODE = XTAL1 + PLL16X _XINFREQ = 5_000_000 DS1820_D_PIN = 17 SCK = 0 ' Max6675 Pin CS = 1 ' Max6675 Pin So = 18 ' Max6675 Pin TempScale = 0 '1 is Farienheight 0 is Centegrade RS = 11 ' LCD Control Pins RW = 10 ' LCD Control Pins E = 9 ' LCD Control Pins DBLow = 12 ' LCD Data Pins DBHigh = 15 ' LCD Data Pins ' ASCII codes. CR = 13 LF = 10 PSTClearScreen = 16 ' One Wire Values . CVRT_TEMP = $44 SKIP_ROM = $CC RD_SPAD = $BE S_Temp = 1600 'Soak temperture to reach S_Time = 120 'Time in sec to soak at given temperture P_Temp = 1900 'Soak temperture to reach P_Time = 60 'Time in sec to soak at given temperture Var Long TempReading1, TempReading2,tell,target,soaktime long numleds_, firstled_, persistence_, leds[7],Power long stack1[64] byte status_reflow OBJ Max6675 : "jm_max6675.spin" '"Max6675_K_thermoCouple" pst : "parallax serial terminal" LCD : "LCD_20x4" num : "simple_numbers" f : "Float32" fp : "FloatString" led : "led_pwm" '==================================================================================== PUB _Start | TimeCnt_10Hz, DisplayTime , ElapsedCnt , index , AddrVar '==================================================================================== Initialize repeat 10 ' Loop in Idle for 10 sec Home Ramp_to_Soak(S_Temp) 'Ramp to soaking temp given to variable Soak(S_Temp,S_Time) 'Soak for some time at give temp Ramp_to_Peak(P_Temp) 'Ramp to reflow temp given to variable Reflow(P_Temp,P_Temp) 'Reflow for some time at give temp Cooling 'Shut off power to cool down back , all finished repeat Home 'Just Loop in Idle '==================================================================================== Pub Home '==================================================================================== status_reflow := 0 leds[0] := 0 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Target_Temp Print_Power_Reflow waitcnt(clkfreq + cnt) '==================================================================================== Pub Ramp_to_Soak(target_Temp) '==================================================================================== Tell:=0 status_reflow := 1 target := target_Temp power:= 50 repeat if TempReading1 < target_Temp Tell++ leds[0] := 32 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Target_Temp Print_Zone_Time Print_Power_Reflow waitcnt(clkfreq + cnt) if TempReading1 > target_Temp return '==================================================================================== Pub Soak(target_Temp,soak_time) '==================================================================================== soaktime := soak_time Tell:=0 status_reflow := 2 target := target_Temp repeat soak_time if TempReading1 < target_Temp power:= 5 leds[0] := 1 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Target_Temp Print_Zone_Time Print_Power_Reflow waitcnt(clkfreq + cnt) if TempReading1 > target_Temp power:= 0 leds[0] := 0 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Target_Temp Print_Zone_Time Print_Power_Reflow waitcnt(clkfreq + cnt) Tell++ return '==================================================================================== Pub Ramp_to_Peak(target_Temp) '==================================================================================== Tell:=0 status_reflow := 3 target := target_Temp power:= 100 repeat if TempReading1 < target_Temp Tell++ leds[0] := 64 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Target_Temp Print_Zone_Time Print_Power_Reflow waitcnt(clkfreq + cnt) if TempReading1 > target_Temp return '==================================================================================== Pub Reflow(target_Temp,soak_time) '==================================================================================== soaktime := soak_time Tell:=0 status_reflow := 4 target := target_Temp repeat soak_time if TempReading1 < target_Temp power:= 5 leds[0] := 1 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Target_Temp Print_Zone_Time Print_Power_Reflow waitcnt(clkfreq + cnt) if TempReading1 > target_Temp power:= 0 leds[0] := 0 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Target_Temp Print_Zone_Time Print_Power_Reflow waitcnt(clkfreq + cnt) Tell++ return '==================================================================================== Pub Cooling '==================================================================================== status_reflow := 5 power:= 0 leds[0] := 0 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Zone_Time Print_Power_Reflow repeat if TempReading1 > 3500 Tell++ leds[0] := 0 LCD.Clear Print_Status_Reflow 'Show status of reflow Print_Max6675_Reading 'Show current temp reading Print_Zone_Time Print_Power_Reflow waitcnt(clkfreq + cnt) if TempReading1 < 3500 status_reflow := 6 return '==================================================================================== Pub Initialize | status '==================================================================================== LCD.Init( E, RS, RW, DBHigh, DBLow ) 'Start The LCD driver in cog0 LCD.Clear 'Clear Back the screen persistence_ := 0 ' Converted a led pwm object to drive the relay , numleds_ := 1 ' By far not the best solution but works :P firstled_ := 22 ' Make sure to change the Fistled_ var to the SSR pin led.start(@numleds_) ' firstled_ := SSR pin cognew(Start_Max6675_Reading,@stack1) 'Start The Max6675 in a new cog Tell:=0 '==================================================================================== PUB Start_Max6675_Reading '==================================================================================== Max6675.start(CS, SCK, So) 'Ini Max6675 repeat TempReading1 := Max6675.tc01 waitcnt(clkfreq + cnt) '==================================================================================== PUB Print_Status_Reflow '==================================================================================== if status_reflow == 0 LCD.RawSetPos( $00 ) LCD.RawWriteStr( string("Status:") ) LCD.RawSetPos( $07 ) LCD.RawWriteStr( string("Idle") ) if status_reflow == 1 LCD.RawSetPos( $00 ) LCD.RawWriteStr( string("Status:") ) LCD.RawSetPos( $07 ) LCD.RawWriteStr( string("Ramp to Soak") ) if status_reflow == 2 LCD.RawSetPos( $00 ) LCD.RawWriteStr( string("Status:") ) LCD.RawSetPos( $07 ) LCD.RawWriteStr( string("Soaking ") ) LCD.PrintStr(num.dec(soaktime)) LCD.RawWriteStr( string("Sec") ) if status_reflow == 3 LCD.RawSetPos( $00 ) LCD.RawWriteStr( string("Status:") ) LCD.RawSetPos( $07 ) LCD.RawWriteStr( string("Ramp 2 Peak") ) if status_reflow == 4 LCD.RawSetPos( $00 ) LCD.RawWriteStr( string("Status:") ) LCD.RawSetPos( $07 ) LCD.RawWriteStr( string("Reflow") ) if status_reflow == 5 LCD.RawSetPos( $00 ) LCD.RawWriteStr( string("Status:") ) LCD.RawSetPos( $07 ) LCD.RawWriteStr( string("Cooling") ) if status_reflow == 6 LCD.RawSetPos( $00 ) LCD.RawWriteStr( string("Status:") ) LCD.RawSetPos( $07 ) LCD.RawWriteStr( string("Cooled") ) return '==================================================================================== PUB Print_Max6675_Reading '==================================================================================== LCD.RawSetPos( $40 ) ' set lcd position LCD.RawWriteStr( string("Actual:") ) LCD.RawSetPos( $48 ) 'set lcd position LCD.PrintStr(num.dec(TempReading1)) 'Display Temp on LCD LCD.RawSetPos( $4C ) ' set lcd position LCD.RawWriteStr( string("C") ) '==================================================================================== PUB Print_Target_Temp '==================================================================================== LCD.RawSetPos( $14 ) ' set lcd position LCD.RawWriteStr( string("Target:") ) LCD.RawSetPos( $1C ) 'set lcd position LCD.PrintStr(num.dec(target)) 'Display Temp on LCD LCD.RawSetPos( $20 ) ' set lcd position LCD.RawWriteStr( string("C") ) '==================================================================================== PUB Print_Zone_Time '==================================================================================== LCD.RawSetPos( $54 ) ' set lcd position LCD.RawWriteStr( string("Time:") ) LCD.RawSetPos( $5A ) 'set lcd position LCD.PrintStr(num.dec(Tell)) 'Display Temp on LCD LCD.RawSetPos( $60 ) ' set lcd position LCD.RawWriteStr( string("Sec") ) '==================================================================================== PUB Print_Power_Reflow '==================================================================================== LCD.RawSetPos( $60 ) ' set lcd position LCD.RawWriteStr( string("Pow:") ) LCD.RawSetPos( $64 ) 'set lcd position LCD.PrintStr(num.dec(Power)) 'Display Temp on LCD LCD.RawWriteStr( string("%") ) '==================================================================================== PUB Get_Power '==================================================================================== LCD.RawSetPos( $00 ) 'set lcd position LCD.PrintStr(num.dec(leds)) 'Display on LCDZip of complete project filesReflow COntroller.zip

p.s. the temptc doesnt return a corrct value , but im using the hole numer reading anyway , but that could need some looking at :P . same for the SSR part . I used a led_pwm object modified , by no way the best solution , but it work , Ill do some more homework to make it better in future