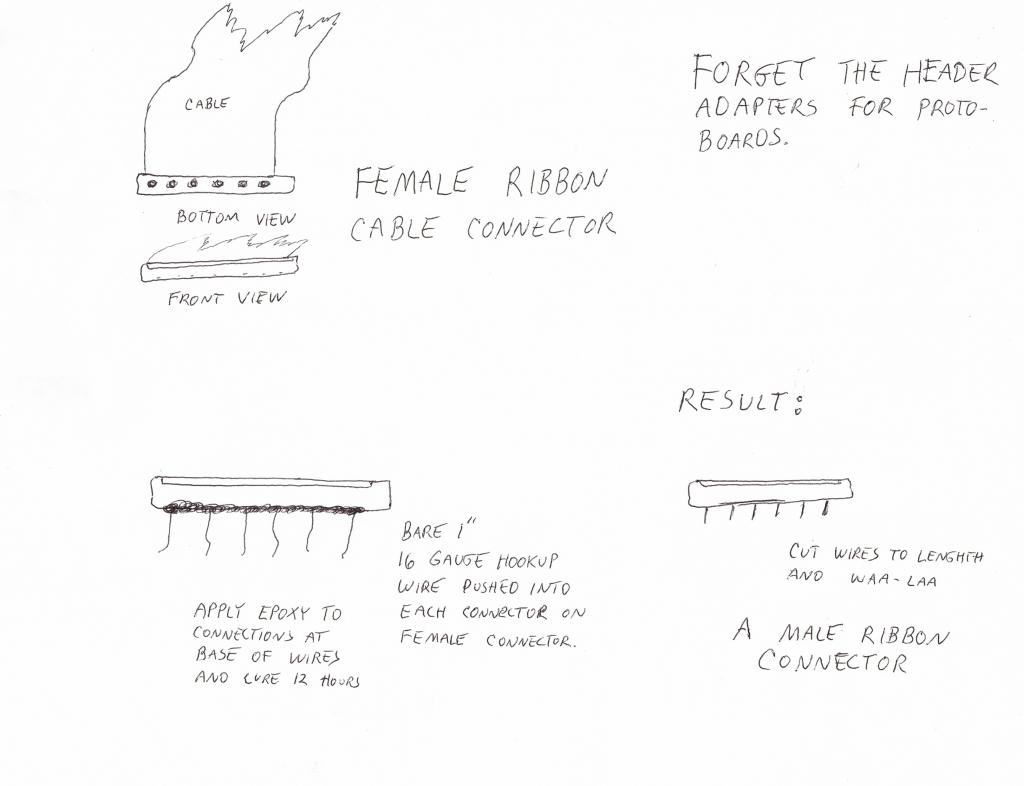

Ribbon Cable Conversion

When working with a prototyping board it is often necessary to connect a servo, sensor or daughter board. Problem? Female connectors on board and females on most cables ect. Usually this is solved by purchasing the header adapter with then needed number of pins ( double male ) and installing into the proto-board to accept the female connector. I have acquired quite a collection of ribbon cables of various sizes and find them great for keeping connections in line,but, they are ALL terminated with FEMALE connectors. My POOR BOY solution is EPOXYING one inch pieces of bared 16 Gauge hook-up wire into the FEMALE connectors and let dry completely (about 12 hours, DO NOT USE JB-WELD). When dry cut the wires EVENLY to length (about 3/8") and you now have a MALE connector that will plug directly into your proto-board.

Tell me what you think? Including drawing of construction. Please excuse the art work

Tell me what you think? Including drawing of construction. Please excuse the art work

Comments

I prefer the double male header option myself.

I might guess you mean "voil

So you are actually using 'the French', and correcting American English again... that English ethnocentricity.

@robomaker

Yep, creativity is welcome. You can use the whole QuickStart modular system if it appeals to you. Or you can modify the boards in ways that might startle the more timid.

I like using the Parallax ProtoBoard and occasionally have cut one end off to make a much more compact arranged. It is quick work with a hacksaw and a file.

Waa-laa, as in Walawala, Washington and Kalamazoo.

http://dictionary.reference.com/slang/wala!

Even there they don't list the version we see here which is hyphenated. I conclude "waa-laa" is not even correct among those who like to spell it the American way.

Maybe I'm a bit over fussy but in the extreme we could all invent our own spellings and grammars and then we would never understand each other.

'Twas brillig, and the slithy toves

Did gyre and gimble in the wabe:

All mimsy were the borogoves,

And the mome raths outgrabe.

Well, you know what I mean!

(I'll say that even if you don't.. just to confuse the issues.)

Spelling checkers worked for a few years to get standardized spelling. But language does have a mind of its own... non-standard pronunciation, non-standard spelling, code switching to other languages (such as viola'), and colloquial usage without dictionary entries.

~~~~

The world is a "Tower of Babel". I am just surprised that the Bible has one tiny paragraph of this subject.

~~~~

What to do? Ask questions, negotiate meaning. We all do invent our own spellings and Creoles or pidgins of a language evolve everywhere.

I guess you would make a great king... somewhere.

I thought I understood what you meant. Until your last post:) That's exactly what I did here. Only someone accused me of "English ethnocentricity".

If I'm not allowed to ask, I can only guess.

If I guess, I may guess wrongly.

If I guess wrongly we might get into a weird situation where I import a word back into English with a different meaning than it had when it was imported into America with the wrong spelling. A horribly recursive loop of errors.

Anyway, for this threads sake I have to say that I like hot glue for this kind of job. It can get messy but that's half the fun. It comes in may colours so you can drop blobs of it on to soldered wire splices and such and add colour coding at the same time.

There are dozens of ways to hack boards to save money. But durable results are also important.

Avoiding an excess amount of connectors and adapters is a good thing. NOt only are they expensive, they can in some cases cause problems.

To do so, I generally buy an appropriate cable with fittings on each end; cut it in half; and solder the cut half to the board. A bit of epoxy might relieve some stresses on a soldered ribbon cable and prevent individual wires from breaking.

I like using a different epoxy putty so it isn't runny like 5 minute epoxy.

It is grayish to greenish in color. I looks kind of like a 1" diameter "jelly role" or log. The epoxy is the cake and the jelly is the hardener The shelf life is a couple of years..

Just slice off a hunk. Fold in half and squeeze flat at least 20 times which makes 1 million layers kind of like puff pastry.

The working time is about 10 minutes. Fairly strong at 1/2 hour and fully hard in a few hours and rock hard over night.

The filler is non conductive unlike JB Weld. OK, not as strong as JB Weld but nice for electronics.

Duane J

SparkFun sells this connectors which they bill as "breadboard friendly". I disagree with it being friendly though. The connector is more likely to break than penetrate the insulation on the ribbon cable and pins are too short and too fat to work well in breadboards.

I like to use PolyMorph for adding stress relief to electronic connections. It clear while it's still hot so you can see how think of a layer you're using and if you want to remove it later on, you just need to heat it back up. I've used PolyMorph on the back side of a circuit board to make a smooth surface which can then be fastened to an enclosure with double sided tape or Velcro.

If the board numbers in another fashion, the actual cable still is every other wire. So once committed to ribbon cables, you have to adjust everything for ribbon cables.

I generally design, build and work with SIP type of cables, such as what Pololu sells. I buy the same locally. I even crimp my own wires and use the cable's flexibility to make them into different sequences at each end. This is extremely handy where one is connecting two boards were built with different ideas about sequence.

And gender is just a matter of what you crimp on the end of the wire.

http://www.pololu.com/catalog/category/39