Could this be handy for DIY PCB fab?

Oldbitcollector (Jeff)

Posts: 8,091

Oldbitcollector (Jeff)

Posts: 8,091

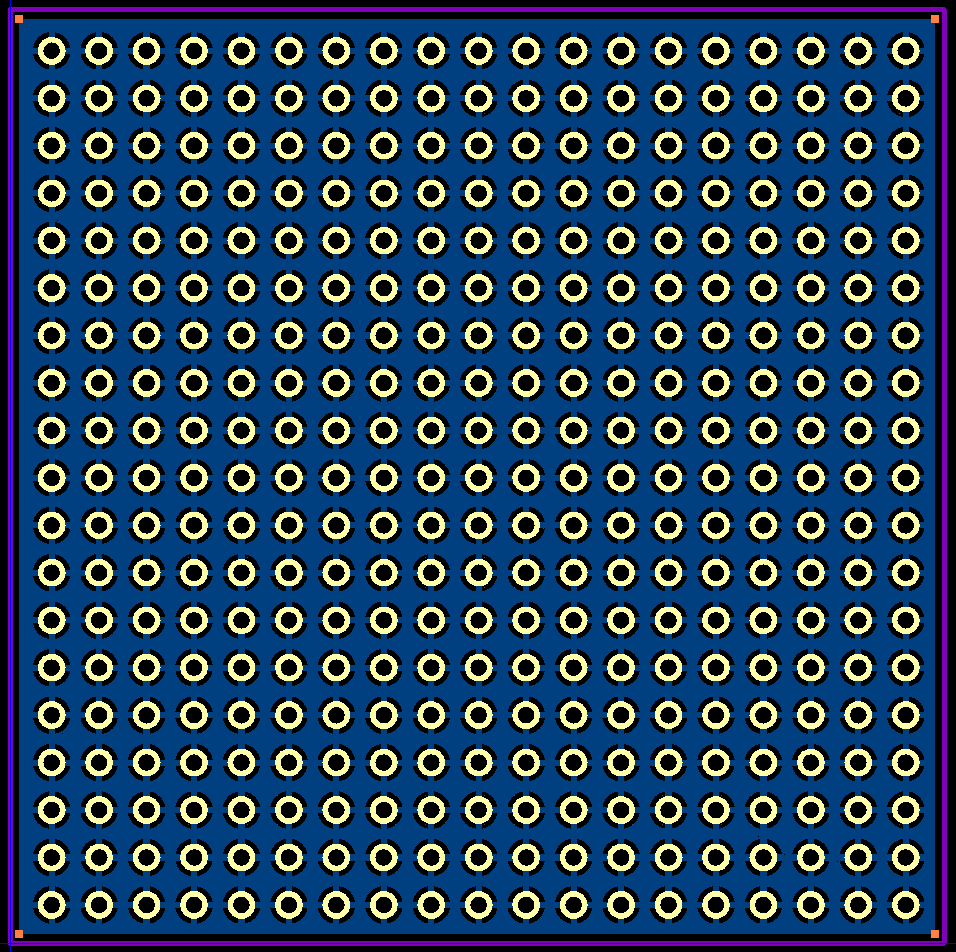

One of the biggest pains in doing PCB fab at home is through-hole parts. Having to drill the holes for your project after you are done.

You can switch to surface mount, but that is a little painful for home hobby circuit builders.

What do you guys think of a pre-drilled board for iron-on transfer designs? Surely I can't be the first guy to think of this. no?

Edit,

Nevermind.. Googled and found my own freak'n post about this two years ago. I didn't have the ability to do PCB design at the time, so I was dependent on finding this already done.

http://search.digikey.com/us/en/products/B3426D/B3426D-ND/354320

Jeff

You can switch to surface mount, but that is a little painful for home hobby circuit builders.

What do you guys think of a pre-drilled board for iron-on transfer designs? Surely I can't be the first guy to think of this. no?

Edit,

Nevermind.. Googled and found my own freak'n post about this two years ago. I didn't have the ability to do PCB design at the time, so I was dependent on finding this already done.

http://search.digikey.com/us/en/products/B3426D/B3426D-ND/354320

Jeff

Comments

I think Jeff was saying for those who don't want to drill a few hundred holes.

You'd have to be really careful on your routing though...

Absolutely - then all that's needed is a software tool to take fritzing diagrams in and generate nc files for CNC / PCB mill...

You can do surface mount with most through hole parts. Just bend the leads so they are flush and parallel with the bottom of the package and use a spot of hot melt glue to hold them in place for soldering. Very easy with IC's, almost as easy for sips, resistors, diodes, and some capacitors.

PS - There is also the "dead bug" as well as the "chip stack" method of building a circuit.