Taming the output of a Bicycle Generator

I'm trying to get a signal from a bicycle generator to trigger an input on a Propeller chip to trigger an event.

Generator:

http://www.amazon.com/Bicycle-Generator-Power-Pulley-Dynamo/dp/B001WB3TZ4

This is a hand crack demonstration application with a 2:1 ratio between the crank pulley and the generator, so it is only putting out 4-5 volts max.

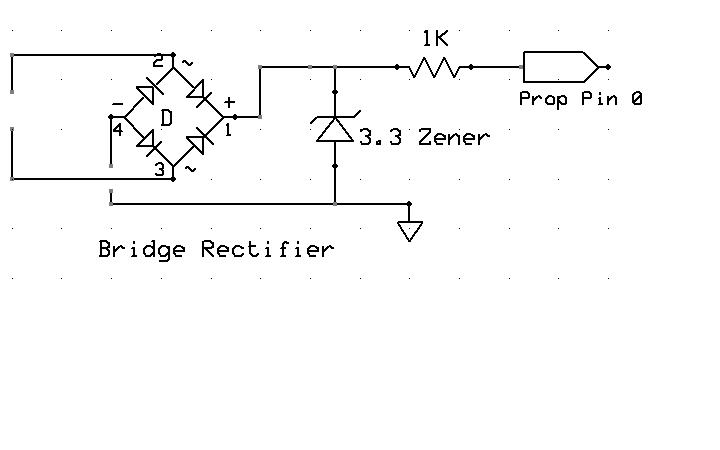

Since you can crank it either way, I have a full wave bridge, and the output clamped down with a 3.3 zener. 1K resistor going to the Prop pin.

Problem is, I keep blowing the pin on the prop after one day of use, (probably 4 hours of off/on use). I'm sure the output from the motor is far from clean, so i don't know if I'm getting spikes.

Any ideas on regulating/filtering? Short of Buck-Boost. I'm on site at a client, shipping from China isn't an option. I do have a Fry's nearby.

I do have a Fry's nearby.

Thanks

Added:

Generator:

http://www.amazon.com/Bicycle-Generator-Power-Pulley-Dynamo/dp/B001WB3TZ4

This is a hand crack demonstration application with a 2:1 ratio between the crank pulley and the generator, so it is only putting out 4-5 volts max.

Since you can crank it either way, I have a full wave bridge, and the output clamped down with a 3.3 zener. 1K resistor going to the Prop pin.

Problem is, I keep blowing the pin on the prop after one day of use, (probably 4 hours of off/on use). I'm sure the output from the motor is far from clean, so i don't know if I'm getting spikes.

Any ideas on regulating/filtering? Short of Buck-Boost. I'm on site at a client, shipping from China isn't an option.

Thanks

Added:

Comments

-Mike

Ouch - the poor Zener is straight across the Generator..

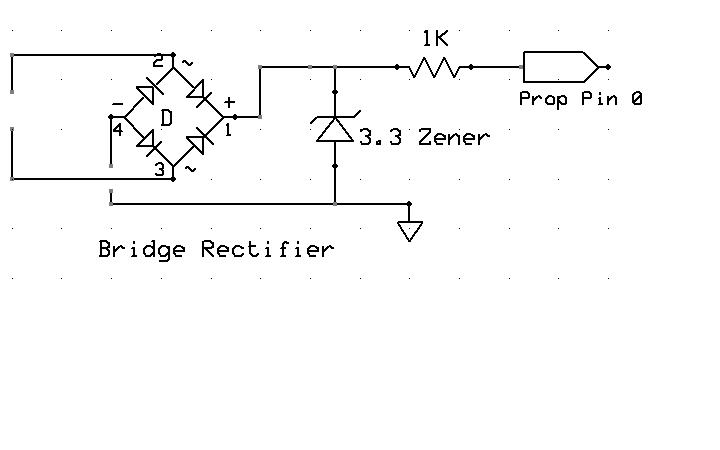

A prop pin needs only uA, and Zener current should be < 20mA, so I would add a 10K before the Zener, and if you want to add a second 10K and Zener in cascade, right at the Prop, that covers for slips too.

Shows my 30 year absence from analog work.

Is this what you propose? :

And thanks for the quick reply!

Oh, and you don't need the zener on the Prop Pin.

Duane J

Yup. - and I'd connect the second zener to the Prop GND.

The first zener can connect to common PSU ground or similar.

Yes, or you may be able to remove the bridge entirely, if the objective is just using this for RPM timing.

In many cases no, but since the OP has already fried some parts, I took a somewhat 'ESD paranoid' approach, and I figured his Zeners cost a lot less than his Props

Is that motor a "Brushless DC Motor", or one that has a commutator?

The BLDC will output the same DC voltage polarity whichever direction it rotates.

The commutator motor reverses polarity.

Either one puts out a relatively steady voltage.

Were you wanting to measure the RPM or something like that?

Cuz I don't think that circuit will do that.

Or just detect that it is turning?

If so why not just an LED?

Duane J

Good point, the link says Brushed DC motor, and it is nominally 3V/500rpm, with bonus brush noise...

If the intention is to detect some speed threshold, then a Low Pass filter could be needed.

{ Prop threshold would be ~250-300rpm }

If it is just a flick=go, then it may be more sensitive without filtering.

@Duane

Secs say: "DC Permanent magnet motor being used as a generator"

Yes it reverses polarity, thus the use of the bridge.

It is just to indicate turning, Once it reaches the Prop threshold, ~1.6 volts, it triggers the rest of the routine. It is meant to stay idle, until someone walks up and turn the crank, and stays running as long as they turn the crank.

I suggested a simple micro switch on the unit, but this was built before I installed the electronics.

Like this?

Either there, or across the Bridge output.

Placing it across the Zener, adds a 2:1 voltage divider, and since this is voltage triggered, that change may not be what you want.

Placing it across the Bridge Output does not change the trip point.

Clamping Diodes as such?

That makes sense.

I'll build it up and install it in the morning. Then let a few hundred kids try to break it!

Do you also have an Effort-based LED, so they can get some visual feedback as they turn the handle ?

Yes indeed! As soon as the handle is turned, enough to generate ~1.65 volts, a series of 6 Electroluminesent panels light up in sequence. The crank must be turned for given amount of time to light all six.