UPDATE: Rocka Pics! Suggestions for SMALL object detection sensors and drive motors

WBA Consulting

Posts: 2,940

WBA Consulting

Posts: 2,940

I am working on a new low-cost and small robot platform (named Rocka) that, for sake of discussion, can be visualized as a miniature Stingray. (~4" wide)

SMALL OBJECT DETECTION SENSORS:

My original plans were to outfit it's face with a set of Ping sensors or Sharp IR sensors for object detection. However, as tiny as the Pings/Sharps are, they would be driving the size of the robot larger than my intentions. I have looked at the Ping kit with the Servo to use one ping, but the standard size servo would be taller than my goal. I could mount a ping on top of a micro servo, but the videos I have seen give me the impression that having to swing a ping around slows down your robot. (maybe I am being mis-lead by the videos?) I haven't got to the point of adding the IR sensors to my daughter's BOE-Bot, so I don't know how well that truly works as compared to Pings. (My Stingray can travel around the house all day without hitting a single thing or getting itself stuck, so I am impressed with the Pings)

SMALL DRIVE MOTOR METHODS

My original plan for drive motors was to modify some micro sized servos for continuous rotation. After searching a bit online, it appeared that the Naro servo that Parallax sells could not be modified, but I of course had to try it myself. The process went rather smooth, but apparently the pot feedback is necessary for the servo to function, so I killed the one I had. I have found several other micro servos, but cannot find any proof of anyone accomplishing this. From what I have found, it seems to be due to people using small gearmotors and H-Bridges instead for this small of a platform. I am trying to avoid an H-Bridge due to the extra real estate it would require on my platform. I have thought of using a mini breadboard and setting up an L293 H-Bridge on it, but my goal is a "simple" solution. When looking at gearmotors, the prices/styles range all over the place and whenever I find a low cost setup, they require mods or are too large. I can use a standard size servo, but it kills my robots real estate.

Any suggestions for small object detection solutions or drive motors for this size of robot?

SMALL OBJECT DETECTION SENSORS:

My original plans were to outfit it's face with a set of Ping sensors or Sharp IR sensors for object detection. However, as tiny as the Pings/Sharps are, they would be driving the size of the robot larger than my intentions. I have looked at the Ping kit with the Servo to use one ping, but the standard size servo would be taller than my goal. I could mount a ping on top of a micro servo, but the videos I have seen give me the impression that having to swing a ping around slows down your robot. (maybe I am being mis-lead by the videos?) I haven't got to the point of adding the IR sensors to my daughter's BOE-Bot, so I don't know how well that truly works as compared to Pings. (My Stingray can travel around the house all day without hitting a single thing or getting itself stuck, so I am impressed with the Pings)

SMALL DRIVE MOTOR METHODS

My original plan for drive motors was to modify some micro sized servos for continuous rotation. After searching a bit online, it appeared that the Naro servo that Parallax sells could not be modified, but I of course had to try it myself. The process went rather smooth, but apparently the pot feedback is necessary for the servo to function, so I killed the one I had. I have found several other micro servos, but cannot find any proof of anyone accomplishing this. From what I have found, it seems to be due to people using small gearmotors and H-Bridges instead for this small of a platform. I am trying to avoid an H-Bridge due to the extra real estate it would require on my platform. I have thought of using a mini breadboard and setting up an L293 H-Bridge on it, but my goal is a "simple" solution. When looking at gearmotors, the prices/styles range all over the place and whenever I find a low cost setup, they require mods or are too large. I can use a standard size servo, but it kills my robots real estate.

Any suggestions for small object detection solutions or drive motors for this size of robot?

Comments

http://www.robot-electronics.co.uk/acatalog/Ultrasonic_Rangers.html

http://www.robot-electronics.co.uk/htm/srf10tech.htm

Otherwise you might want to use a single transducer solution.

For motors, SolarBotics sells lots of tiny, tiny gearmotors:

https://solarbotics.com/catalog/motors-servos/gear-motors/

It looks like you have some room on the front of Rocka to hang a Ping(((,

Then you could have both IR and Sonic detection, and still have room for the Rocket Launching System...

-Tommy.

The problem with the micro servo is the pot is also an axle. You'd need to add a secondary pot to adjust the zero point. I've taken about several of these servos myself and I've be concerned about the strength of axle/pot to hold a wheel but I'm not sure it would be a bad idea.

I've used a bunch of HXT900 servos in various projects and they've worked very well (and they're nice and cheap). I intend to try them as CR servos sometime.

I have converted a micro servo to continuous rotation. It is a pain but can be done.

1) Pick a micro servo that has a full gear. Some only have a 1/2 gear.

2) You have to cut off the small metal part on the pot that stops it from going around 360. You have to be careful since the pot is also used as an axle.

3) Cut the wires from the pot and solder them to two resistors (in my case they were 4.7k). In the servo I used there was no room inside the servo so I had to glue them to the outside of the case.

I don't know why people think they need to keep the pot in the servo. Two resistors work fine and most of the time they keep the motor at a null point. Even if the motor does move a little you can always null the motor in software.

Al

Object Detection:

Looks like I will be trying simple IR like used for the BOE Bot. I just can't seem to find any ultrasonic or IR modules that fit my size goal.

Drive Motors:

From what I have found, I am going to be taking apart the Naro servo again to resolve a few "I wonder if" ideas that have come up. I will also be picking up some of those HXT900 servos and following this set of instructions. I would prefer to use W9GFO's mentioned gearmotors as I was already looking at them, but I was trying to avoid an H bridge. I will keep searching for a dirt cheap H Bridge setup though.

Thanks to everyone for all of the posts, They have given me much more knowledge into small robot design.

I am still finalizing the chassis drawing, but the prototype will probably be made from 0.2" thick MDF. However, I am looking at some 1/16" thick polystrene as I have recently learned some clever tricks for interlocking perpendicular joints of very thin material.

You might want to also read erco's notes about his conversion. He'll be glad to know someone else cares.

It might be easier to attach a wheel to the metal final gear than the HXT900's plastic final gear. I haven't used these servos myself, but they look pretty good for the price. I'm not sure if the metal gear servo has a full final gear or not. I think the odds are high it's a full gear since it normally has a full 180 degrees of rotation.

I took apart the naro servo again and see what I need to do to finish the conversion. I know have the pot disconnected from the PCB. The lead spacing on the pot appears to be perfect size to squeeze in an 0603 resistor. Will have to try that. The naro servos aren't cheap though, but at least I know a bit more about what I am doing. I also keep going back to the cheap H-Bridge and $5 gearmotor solution. I did also just find this one at Sparkfun. According to the drawing, the size would be excellent and it is already continuous rotation. I think I missed it before because it is called a medium servo, which I interpreted as "standard" so I ignored it.

Not sure what dirt cheap is but one of these will drive two motors for $2, or just $1 in large quantitities.

If you went that route you could use a dual gearbox from tamiya that comes with two motors for 11 dollars.

What would be the benefit of using the L293 over the newer SN754410NE?[h=1][/h]

I definitely meant just throwing the chip on a PCB or protoboard not buying an overpriced module, the chip is very easy to connect with proper schematics anyone that can solder is capable of repeating the board

https://solarbotics.com/catalog/phidgets/

http://www.amazon.com/TAB-Electronics-Build-Your-Robot/dp/0071387870

I did finally find an inexpensive motor driver at Pololu: http://www.pololu.com/catalog/product/2135

I will be moving forward with modified Naro servos for my prototype though. Once complete, I will make a version for the 2135 motor driver.

The Nordic modules aren't as simple to use as XBees but they sure cost a lot less. (Note the link is to a batch of ten modules which still cost less than a single XBee.)

Excellent point, those Nordic modules would take up much less space. I will definitely look into them. I think my second version will be based upon an H bridge an DC motors, so with the Nordic module, the overall robot won't have to be squeezed into the form factor.

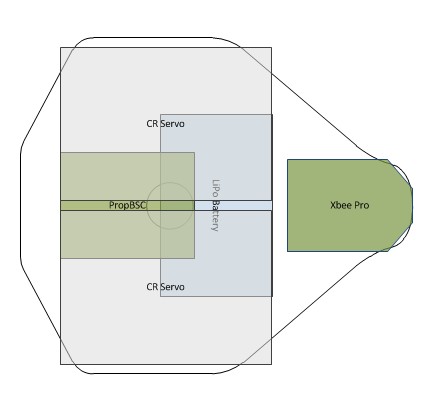

2 GWS Naro micro servos modified for continuous rotation

My PropBSC module

XBee Module

Miniature Breadboard

IR Transmitter/Receiver Kit

Sparkfun LiPo battery

Lasercut MDF chasss (it's actually chalkboard precoated 0.2" MDF. Cuts and etches really nice)

some pics are attached............still need to figure out my final configuration and whether or not I can get that pin on there.

These are turning out really neat!

The bottome deck is motors and battery and the upper deck is brains and sensors?

I can see a swarm of these guys in the future!

Well done!

I have an Arduino based robot that's designed like this. It's actually called a Robot Shield, I believe alluding to the way it fits onto an Arduino like a shield. I've also seen others where the expectation is to flip over the controller board and just plug it into the robot.

Of course, the big question is... "Once you get these closer to perfected, are they going to be for sale??"