Simple and cheap encoder idea

pedward

Posts: 1,642

pedward

Posts: 1,642

What has 3 rotary encoders, 3 limit switches, costs $3 and already works with the Propeller?

A PS2 wheel mouse with ball.

I had this idea the other day that I could rob the parts from a ball-mouse and use them as feedback for a closed loop motion control system driven by the Prop. As luck would have it, I got a surplus ball-mouse from Church this afternoon.

When tearing apart disused inkjet printers, it's become a lot more common to see a servo controlled print head with linear encoder instead of stepper motor. The paper feed path is the same. This actually makes a lot of sense, the linear encoder has become necessary as resolution and speed has increased, and steppers are more expensive than little brushed DC motors.

It then occurred to me that I could take the wheels out of a mouse and drill them to fit the end of a ball screw, or a pulley on a belt.

The mouse driver on the Propeller performs 200 samples per second, 5ms resolution. That's pretty decent when you consider a speed like 100ipm is 60 x 100 x 200 = 1.2 million samples in that period of time. If you are using a 5TPI screw (very common) then you'd have 100 * 5 = 500 revolutions per minute and 1.2-e6 / 500 = 2400 samples per revolution.

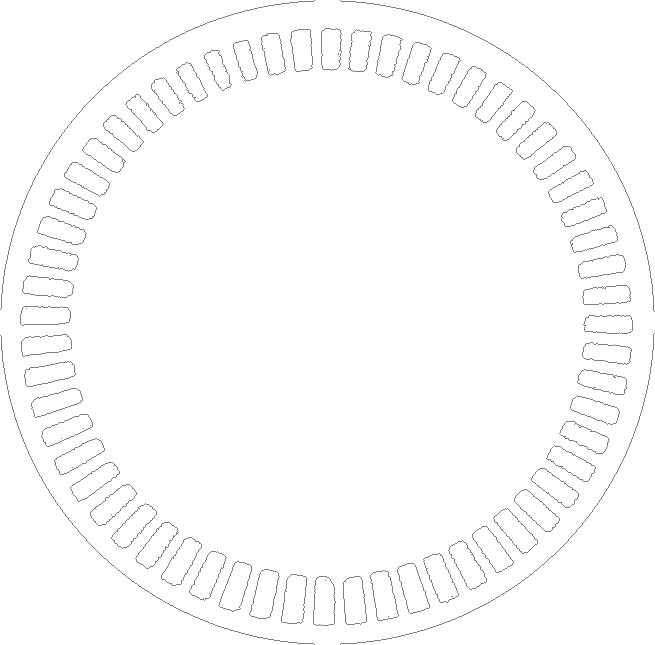

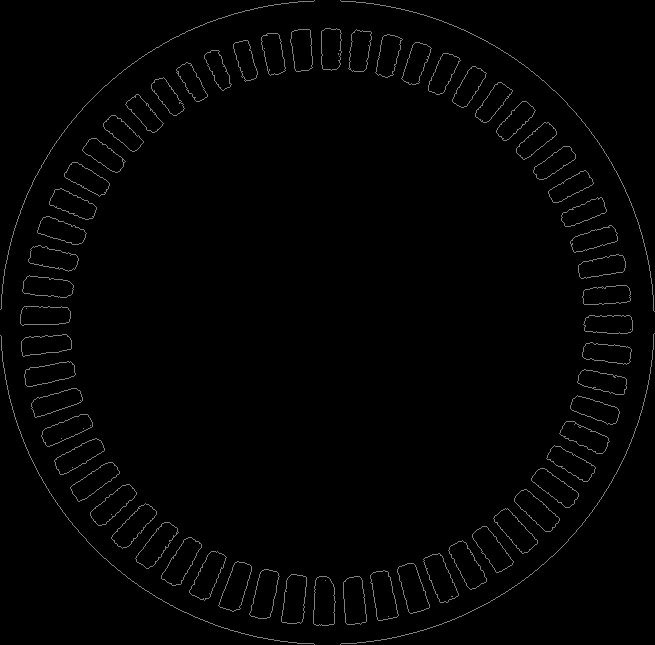

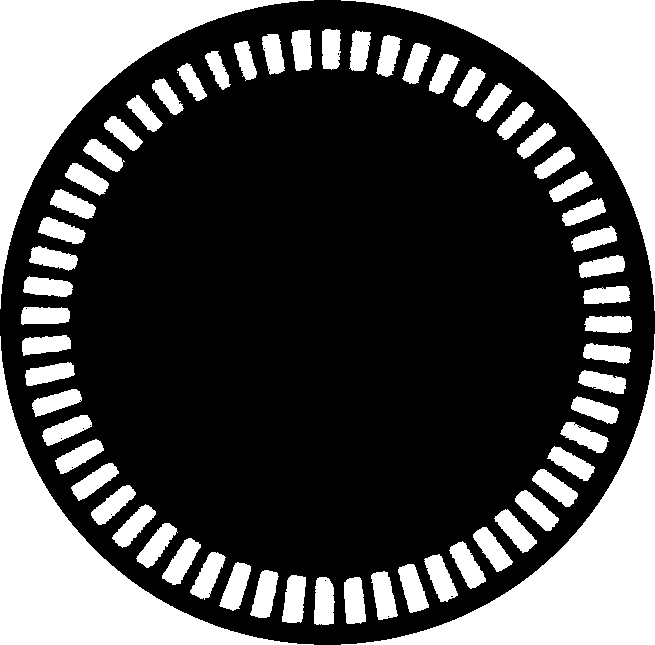

I have a picture of the encoder wheel I'll post once I reboot (USB crashed because of some old crappy peripheral).

EDIT: Ok, I got the picture off my phone and edited it in GIMP to get something useful.

The encoder wheels in my mouse have 60 divisions per revolution. That's pretty low when you look at machine resolutions. That would amount to 60 * 5 = 300 counts per inch or 300 dpi (curious). That's about 3.3 thousandths per count, which isn't very high resolution.

Resolution could be easily increased by printing an encoder wheel on transparency material, then attaching this to a stiffer backing. You can also use scavenged parts from a printer, including the optical sensors originally used by the printer. A quick search on digikey returns this part: http://www.digikey.com/product-detail/en/EE-SX1131/OR628CT-ND/355301 which could be used for a custom sensor board.

The funny part is you could connect these directly to the Prop and avoid the mouse electronics, but the mouse provides information about delta instead of sampling directly, so you've got 3 encoder channels that are tracked by a "co-processor" that is the mouse chip.

It's a neat idea that might prove useful for applications where lower resolution isn't a problem (dog feeder?).

A PS2 wheel mouse with ball.

I had this idea the other day that I could rob the parts from a ball-mouse and use them as feedback for a closed loop motion control system driven by the Prop. As luck would have it, I got a surplus ball-mouse from Church this afternoon.

When tearing apart disused inkjet printers, it's become a lot more common to see a servo controlled print head with linear encoder instead of stepper motor. The paper feed path is the same. This actually makes a lot of sense, the linear encoder has become necessary as resolution and speed has increased, and steppers are more expensive than little brushed DC motors.

It then occurred to me that I could take the wheels out of a mouse and drill them to fit the end of a ball screw, or a pulley on a belt.

The mouse driver on the Propeller performs 200 samples per second, 5ms resolution. That's pretty decent when you consider a speed like 100ipm is 60 x 100 x 200 = 1.2 million samples in that period of time. If you are using a 5TPI screw (very common) then you'd have 100 * 5 = 500 revolutions per minute and 1.2-e6 / 500 = 2400 samples per revolution.

I have a picture of the encoder wheel I'll post once I reboot (USB crashed because of some old crappy peripheral).

EDIT: Ok, I got the picture off my phone and edited it in GIMP to get something useful.

The encoder wheels in my mouse have 60 divisions per revolution. That's pretty low when you look at machine resolutions. That would amount to 60 * 5 = 300 counts per inch or 300 dpi (curious). That's about 3.3 thousandths per count, which isn't very high resolution.

Resolution could be easily increased by printing an encoder wheel on transparency material, then attaching this to a stiffer backing. You can also use scavenged parts from a printer, including the optical sensors originally used by the printer. A quick search on digikey returns this part: http://www.digikey.com/product-detail/en/EE-SX1131/OR628CT-ND/355301 which could be used for a custom sensor board.

The funny part is you could connect these directly to the Prop and avoid the mouse electronics, but the mouse provides information about delta instead of sampling directly, so you've got 3 encoder channels that are tracked by a "co-processor" that is the mouse chip.

It's a neat idea that might prove useful for applications where lower resolution isn't a problem (dog feeder?).

Comments

You could use the rotary encoder with either continuous or standard rotation servos. In standard rotation it would be a 6 degree resolution direct reading encoder. For continuous rotation it would be a simple fire-and-forget motion control.

Let's say you have a belt driven carriage, like on a scanner or printer. You replace all of the gear reduction (with resultant lash stackup) with a direct drive continuous rotation servo, then put a printed encoder wheel on the pulley. Read the encoder wheel with the mouse guts (perhaps using a remote sensor scavenged from a printer) and you've got a very simple to interface motion control.

The mouse keeps track of the absolute location, presumably 1 count per division. You locate home, reset the mouse, then use a loop that targets a specific mouse location with the servo output driven at a given speed, preferably all in a PID loop.

You could reuse the linear encoders from a printer or print some.

This solves the problem of having a motor driver and power source, since you just use a regular servo. Servos aren't particularly fast, but they're easy to interface and they're self contained.

You could practically modify the Mouse driver to poll more than 1 mouse at a time, giving you multiples of 2 or 3 axes, depending on the mouse.

Super low pin count and easy to interface to. When I get some time I'll knock together a test. I've got a short linear slide, leadscrew, servo, and encoders/sensors from printers.

http://www.mouser.com/Search/Refine.aspx?N=1323043&Keyword=AEDR&Ns=Pricing%7c0&FS=True

Ive seen binary counters along with some other 74xx chips set up to do quadrature decoding, but this may be a simpler solution. I do how ever wonder if the mouse can keep track of a 1000 ticks per revalution, as this seems pretty common when discs are placed before gearing on a standard dc motor

http://www.ebay.com/itm/FAST-SHIP-iMicro-MO-1008P-Optical-PS-2-Mouse-Black-/190749169148?pt=Mice&hash=item2c698955fc

Here's a video of the demo I made:

[video=youtube_share;EUquqGbbxx4]

The other PID is PID1_1 and I liked the thought put into scaling, fixed point math, and they tried to do some best effort upgrades to the Arduino code it was inspired by. The problem with this code was twofold: It has severe integral windup, making it very difficult to use properly, and there isn't any time delta weighting because the code it was copied from assumed you called it at least once per second (in the example).

Without the time delta weighting, the decay rates of Integral and Derivative don't work properly, because it's not synchronously tied to a unit of time. I fixed this problem by keeping track of CNT and only processing the PID loop if at least 1ms had passed, making the maximum bandwidth of the algorithm 1Khz. I followed the code the ORIGINAL author wrote and just hardcoded the time delta at 1ms.

For Integral windup, I took a simple approach, I only start processing the Integral if the error is within 20 counts, this prevents the Integral overshoot caused by windup. This could be made a tunable, but it works with the hard coded value. The loop runs as a PD controller until the error is within window, then it converts to PID. This seems to work nicely, even just P control was working pretty well with the test rig.

Here's the modified PID routine:

PUB PID_Compute(vInput) ' vInput is the process variable ' returns a scaled output ' Takes raw input in 100th degree and returns scaled and limited output PID_Input := vInput If PID_Auto 'Compute all the working error variables PID_cnt := cnt if PID_lcnt > PID_cnt PID_tdelta := $FFFF_FFFF - PID_lcnt + PID_cnt else PID_tdelta := PID_cnt - PID_lcnt PID_tdelta := PID_tdelta / (clkfreq / 1000) if PID_tdelta >= 1 PID_Error := PID_SP - PID_Input if ||PID_Error < 20 PID_errSum += PID_Error PID_ITerm += (PID_KI * PID_errSum) PID_ITerm <#= PID_OutMax 'Limit ITerm max to the OutMax PID_ITerm #>= PID_OutMin 'Limit ITerm min to the OutMin else PID_ITerm := 0 PID_Derr := (PID_Input - PID_LastInput) 'Compute PID Output PID_Output := (PID_KP * PID_Error) + (PID_ITerm) - (PID_KD * PID_Derr) PID_Output <#= PID_OutMax 'Limit ITerm max to the OutMax PID_Output #>= PID_OutMin 'Limit ITerm min to the OutMin PID_LastInput := PID_Input PID_Lcnt := PID_cnt return PID_Output / PID_OutScale else return 0And here is my demo program:

{{ PS2 encoder feedback to servo }} CON _clkmode = xtal1 + pll16x _xinfreq = 5_000_000 'Note Clock Speed for your setup!! PS2_data = 27 PS2_clock = 26 Servo_P = 0 OBJ mouse: "Mouse" servo: "Servo32v5" pst: "Parallax Serial Terminal" pid: "PID1_1" VAR long output 'PID Output PUB main mouse.start(PS2_data, PS2_clock) mouse.bound_limits(0, 0, 0, 32767, 32767, 0) mouse.bound_scales(1, 1, 0) servo.start pid.PID_Init pid.PID_SetOutLimits(-1000000,1000000,1000) 'Output limits are before scaling, this will give a 0 - 200 output pid.PID_SetTunings(51,5,7) 'Pick some good numbers for the P, I, D, pid.PID_SetState(true) 'Enable it. pst.start(115200) move(500) waitcnt(clkfreq / 10 + cnt) move(750) waitcnt(clkfreq / 10 + cnt) move(900) waitcnt(clkfreq / 10 + cnt) move(100) waitcnt(clkfreq / 10 + cnt) move(200) waitcnt(clkfreq / 10 + cnt) move(100) repeat PUB move(setpoint) |x pid.PID_SetSP(setpoint * 100) 'PID setpoint is before scaling eg, 25c repeat until x == setpoint x := ||mouse.abs_x output := pid.PID_Compute(x * 100) servo.set(Servo_P,output+1500) servo.set(Servo_P,1500)move(500,1000) ' waitcnt(clkfreq + cnt) move(750,200) ' waitcnt(clkfreq + cnt) move(100,50) move(900,100) ' waitcnt(clkfreq + cnt) move(200,30) ' waitcnt(clkfreq + cnt) move(100,10) servo.set(0,1500) repeat PUB move(setpoint,speed) |x pid.PID_SetOutLimits(-speed*1000,speed*1000,1000) 'Output limits are before scaling, this will give a 0 - 200 output pid.PID_SetSP(setpoint * 100) 'PID setpoint is before scaling eg, 25c repeat until x == setpoint x := ||mouse.abs_x output := pid.PID_Compute(x * 100) servo.set(0,output+1500)