Cheap Bot, A Possible BSA Robotics Merit Badge Robot

Duane Degn

Posts: 10,588

Duane Degn

Posts: 10,588

I've already posted this video in the Figure 8 Thread.

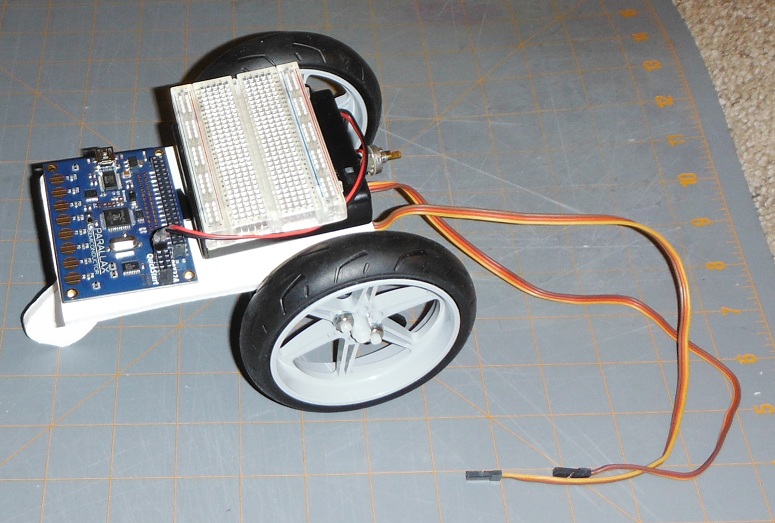

This is my attempt at building an inexpensive robot.

I'm not currently a Merit Badge Counselor, but I'm considering applying to be one. I've been trying to figure out ways of making it easier for scouts to learn about robotics as others are discussing in this thread.

I'm hoping this robot can be an example of how relatively easy is can be to build a custom robot.

My main concern with is Robot is the Lego wheels. While these wheels were easy to attach to the servos, I can't expect scouts to have access to wheels like these. I'll likely modify this robot to use jar lids (as used in PJ's "Cypherbot") or some other form of inexpensive wheels.

See post #2 for the latest software to use with this robot.

Post #3 has some pictures showing the construction process and a bill of materials.

This is my attempt at building an inexpensive robot.

I'm not currently a Merit Badge Counselor, but I'm considering applying to be one. I've been trying to figure out ways of making it easier for scouts to learn about robotics as others are discussing in this thread.

I'm hoping this robot can be an example of how relatively easy is can be to build a custom robot.

My main concern with is Robot is the Lego wheels. While these wheels were easy to attach to the servos, I can't expect scouts to have access to wheels like these. I'll likely modify this robot to use jar lids (as used in PJ's "Cypherbot") or some other form of inexpensive wheels.

See post #2 for the latest software to use with this robot.

Post #3 has some pictures showing the construction process and a bill of materials.

Comments

The software includes a ramping method to provide smoother servo control and to limit current spikes cause but abrupt speed changes.

Neither of the pieces where measured. I just help up the pieces I wanted to fit on the robot and cut the rectangle to general size I wanted. The tail dragger was made long enough to keep the robot relatively level with wheels I planned to use.

I used Gorilla Tape to attach the tail dragger piece to the rest of the chassis.

I used some hook and loop material that's different than the usual "Velcro". This particular product sticks to itself so it doesn't require two different types of material.

I used this material to secure the battery pack to the chassis and the voltage regulator to the battery pack.

I used "servo tape" to attach the continuous rotation servos to the chassis.

The breadboard was secured to the battery pack with double sided foam tape (included with the breadboard).

I initially used NiMH cells in the battery pack since four NiMH cells are close to 5V and can be safely used to power the servos directly. I found the change in voltage over time from the draining batteries made the speed produced by the continuous rotation servos inconsistent between runs of the robot.

My solution to produce a more consistent speed was to use four Li-Ion cells and then regulate the voltage down to 5.0V. This power supply system worked much better than the original NiMH system.

The switching regulators from ebay had solder pads for additional capacitors which I used to solder headers to the PCB to make it easier to connect the regulator to the power supply and the breadboard power rails.

The regulator on the right (in the above photo) is how the regulator originally came from the seller. The regulator on the left is the modified version with headers soldered to the board.

Edit: See post #5 for more assembly photographs. I was going to add them here but the forum software limits attachments to ten (I have eight so far and I wanted to add three more).

See post #4 for a bill of materials.

Propeller QuickStart Board (Parallax) $25.00 The QuickStart Price has increased to $35. I now suggest using the Propeller Project Board

Propeller Project Board (Parallax) $25

Switching voltage regulator (ebay) $2.90

Li-Ion AA batteries (ebay) $1.30 x 4 = $5.20 (10 are sold for $12.99)

HXT12K metal gear servos (HobbyKing) $7.97 x 2 = $15.94

Battery case with switch (Radio Shack) $2.29

Breadboard (SparkFun) $5.95

Male headers (SparkFun) $1.50

Female headers (SparkFun) $1.50

Extra long male headers (SparkFun) $3.50

(5/10/13)Vex 2.75" Wheels $2.50 x 2 = $5.00 (sold in sets of four) I haven't tested these yet. See post #41 for discussion.

Command Brand Picture Hanging Strips

Servo tape or other double sided foam tape

Gorilla Tape (or other strong tape)

Foam board

See "Similar Threads" below for other ideas about making inexpensive robots for the BSA Robotics Merit Badge.

****** I'm still working on this post, check back later for more detail and better photo captions. *******

Though I intend to use different wheels, I thought I'd try to show how these Lego wheels are attached to the servos.

The above photos show the nylon bolts I used to both secure the wheels to the servo horn and to secure the servo horn to the servo. I used nylon bolts in hopes of minimizing any damage to the Lego wheels (I may sell the set they are from at some point in the future).

I removed a central raised section on the servo horn in order to get the wheels to sit flush agaist it.

[Add photo of servo horn here]

I'm using a Wixel to wirelessly program this and other robots. Though not included in the BOM, I thought I'd share my adapter board I made to make it easer to use with a QuickStart board or a Propeller Proto board.

Aboved shows Wixel board pluged into QuickStart.

Above shows bottom of adapter board. Below shows top of adapter board.

Maybe I can get some 4-H kids interested in something like this for projects this year!

Thanks, one of my goals with this project was to show how is doesn't have to be hard to make a robot. I can't think of a better subject than robotics to interest kids in STEM type subjects.

This crossed my mind. Erco has converted one of the cheap micro servos to CR but it didn't look like the axle would be very strong (since it's part of the poteniometer). I doubt I'll try using the micro servos anytime soon.

These metal gear servos are some of the easiest servo I know of to convert to CR. I also like the 3mm threads used to hold the servo horn in place since it is a common screw size (metric). It makes it easy to use long screws when needed to help mount wheels to the servos.

I also like the power of these metal gear servos. You might have noticed in the figure 8 video how even when the robot ran into the pie tin, it was still able to push itself along without getting stuck.

http://hackaday.com/2011/07/23/cypherbot-uses-older-uc-and-retro-controller/

The foam board is a good solution, particularly for first timers. I think we will use that.

I tried the peanut butter jar lids method, but did not figure out how to get them centered before I ran out of lids. The wheels continue to be a significant expense because of the centering and hub attachment to the motors.

I once "converted" a micro servo to continuous rotation but running it a 7 volts and it blasted through the end stops, so we switched to the cheap steppers. We did not do testing yet.

Either may be the most frustration easing money you've spent in a long time!!

Don't buy when you can Make! :>)

http://www.instructables.com/id/Make-a-Center-Finder/

I read you comment in the Merit Badge thread about the boys needing to design and build their own bot. I think the foam board makes this possible.

The foam board is easy to cut with a razor knife but I'm uneasy with the thought of a dozen or so scouts using a X-acto knife. I suppose the cutting could take place at a supervised location with the boys drawing the patterns they plan to use ahead of time. (I know scouts are supposed to be able to use knives but I don't know how many have experience with X-acto type knives.)

Once a shape/design has proven satisfactory, the same shape could be cut from a more durable material.

One possibility is to loan the hardware instead making the boys buy it. They could have the option of just borrowing the hardware while taking the merit badge course. It's the kids that can't afford $50 or $60 that I'd most like to see learning about robotics.

I still have no idea (at least not much of one) of how to conduct a robotics clinic. I'm keeping my eye on the other threads for ideas how to do this.

My experience showing a dozen (maybe just 8) cub scouts how to wire a LED on a breadboard taught me I'm really bad at judging how long an electronics activity will take. My LED experience did reinforce my belief that electronics and robotics are topics boys (and I hope girls) are very interested in. The cub leaders commented that they had never seen the boys so quiet and "on task" for as long as these boys had been for any other scouting activity.

As I type this, I realize I'm going to need to make sure I figure out a way to give girls the same chance to learn this stuff as I plan to give boys. I know some 4-H leaders, I'll probably talk to them about this.

@PJ, Thanks for the Instructables link. I just had your blog post listed in my index so I used it in my original post.

I'm interested in seeing what Jeff comes up with with his cheap bot. I've always had good service from his PropellerPowered store.

What you propose utterly flies in the face of Cal, from the movie "Titanic", of his fiance Rose: "Women and Machinery do not mix."

Even cheaper! http://www.hobbyking.com/hobbyking/store/__26248__Simple_Expandable_Robot_Chassis_KIT_.html just add a controller and motor driver to this bad boy! Theres a 16 dollar arduino/motor control board on Rocket brand also, so a $26 dollar bot, that has a caster and a rigid body

The foam board is a good idea Duane, I use a lot of it in my projects. The local Tap Plastics has a "cutoff bin" where I get a 'lot' of expanded PVC board (and other plastic stock) for about $1.70 a pound. The stuff is easy to work with and for joining parts parts solidly, PVC pipe cement is perfect.

@

Never thought of that Doc. I've just been bolting up aluminum reinforcement or gluing on additional plastic.

http://letsmakerobots.com/node/35795

Just you watch it, Bub!

Amanda

Haven't seen any figure 8s from you lately, Amanda. Wassup wit dat?

For example: http://blog.makezine.com/2012/11/09/prop-building-with-pepakura-and-papercraft/

Well, we came close with Wilbur I, but it was more like two loosely related zeros than a eight.

Been experimenting with the new layout and found the four wheel drive, center pivot design is really tricky to steer. Short turns (90 degrees or less) aren't too bad, but trying something like a figure eight is tough. The longer the turn, the sharper the chassis wants to make the turn and it keeps spiraling inward. It's fixable, but there are several other shiny things vying for my attention at the moment.:nerd:

@

I went with 3m/scotch mounting squares on mine (the other cheap robot thread) and they are working perfectly. Nice and strong. (So much so, I'm a little worried when I start yanking it apart for a revision.)

Jeff

Do you have a free pivot there? Could you benefit from a "return to center" spring, or a servo to control the angle?

The "servo tape" I used doesn't stick as well as I'd like. I've had the servo come unattached to the robot several times when it has been bumped too hard. I may switch to some 3M stuff.

Some double sided tape products have tabs to pull when you want to remove the tape. It makes it a lot easier when it's time to undo a bond when there are those little pull tabs.

Another thing to do with tape that's stronger than desired is to just use less of it. I often just use a square centimeter of the stuff than I don't want to permanently attach two items.

I'm looking forward to seeing your inexpensive robot in action.

Yup... the center pivot is free. I thought about using hard stops, but I kinda want to work this out in code.

It =looks= like the servo speeds have to be continuously changed during a turn.

Anyway, I'll whine more about this in the Wilbur 'Bot thread!