RFID for Fixture ID

JordanCClark

Posts: 198

JordanCClark

Posts: 198

For those waiting breathlessly for the answer to the burning question asked in this thread, I've done 5m with no issues.

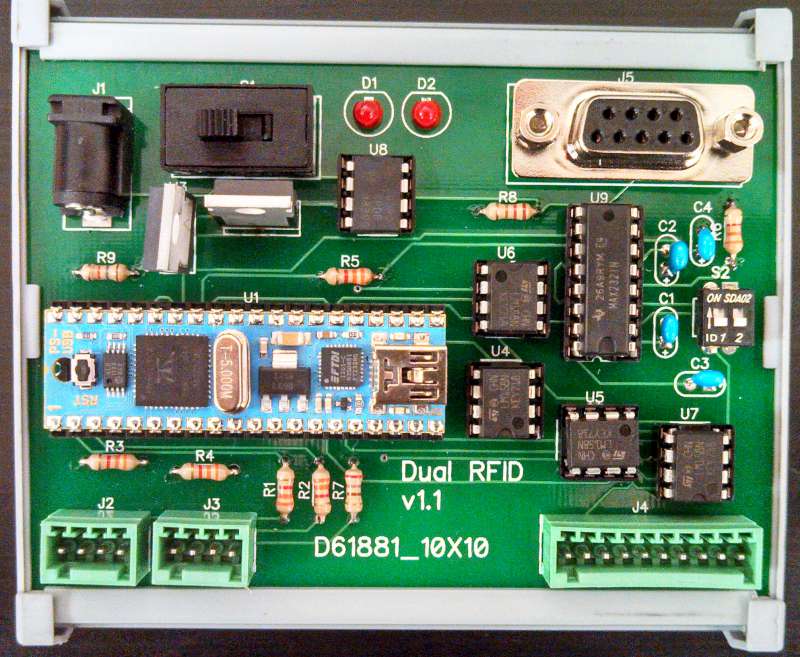

My application was to use a pair of Parallax RFID Read/Write modules for Identifying fixtures on an assembly machine.

Working setup with 30mm tag flush mounted in the fixture, and the RFID module in a custom UHMW housing flush-mounted in the table. This gives approx. 2mm distance between reader and tag (the thickness of the housing), with a maximum read distance of approx. 6mm. :cool:

So, here are some pics, along with what I've got for programs and documentation so far.

Edit: forgot to re-encode the pics in the documentation file to make overall size much smaller-- 7.5M down to 155k-- easier downloads for everyone!

Edit: Changed prefix to complete.

My application was to use a pair of Parallax RFID Read/Write modules for Identifying fixtures on an assembly machine.

Working setup with 30mm tag flush mounted in the fixture, and the RFID module in a custom UHMW housing flush-mounted in the table. This gives approx. 2mm distance between reader and tag (the thickness of the housing), with a maximum read distance of approx. 6mm. :cool:

So, here are some pics, along with what I've got for programs and documentation so far.

Edit: forgot to re-encode the pics in the documentation file to make overall size much smaller-- 7.5M down to 155k-- easier downloads for everyone!

Edit: Changed prefix to complete.

Comments

So, what *IS* the answer to the burning question????

I'm pretty sure the answer is 42, we just don't know 42 what...

Enjoy!

Mike

My day job continues to suck away any intellectual potential for the time being, so the best I can offer at present is questionable comic relief.