Corrosion proof substitute?

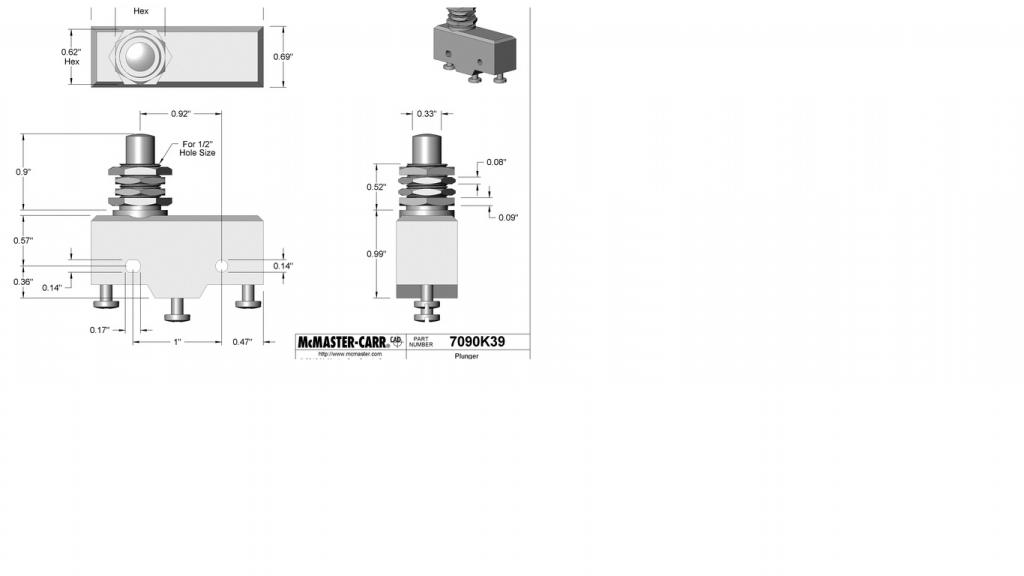

I use this plunger as a limit switch. In a first use on a boat, the plunger has stuck pressed in, supposedly it is corroded and no longer is free to move. The switch is in a tight condition and cannot be replaced with a something larger in any direction. I cannot find a corrosion proof drop in. The plunger travels around 3/8" and some travel is required for the system to decelerate to a stop upon contacting the switch. I have to send a replacement out first part of the week. One idea is to fill the button part with marine grease, and hope to gain a few years at least if not more of free movement. The switch rarely gets used, only in a power off condition, so it stays fully extended most of it's life with little exercise. Another idea is to replace it with the same and attempt to seal the switch with a plastic bag or rubber cover. I am looking for any suggestions to solve this problem, suggestions are appreciated. One photo shows the actual plunger stuck pressed in, it is attached to the plastic mount.. normally the plunger sticks out of the plastic by 3/8" and the plastic takes any punishment if the system doesn't stop the travel in time. There are not options to change the circuit or wiring options at this point. The contacts are normally closed, a Prop reads an input pulled low by the switch. When the switch is pressed, the contacts open, the input is held to 3v3 with a 10k, the Prop sees 3v3. There are two of the systems. One is frozen, and I am told the other is becoming difficult to press in, so it is the same corrosive effect on both.

Comments

EDIT: Never mind, that would require power

-Phil

-Phil

Have you tried searching for "washdown" or "food-grade" switches? Those two keywords should find a lot of industrial switches meant for similarly difficult situations. Also, searching http://www.thomasnet.com/ and calling several switch manufacturers (especially the small ones) can find solutions fast.

Lawson

If you do add zinc to prevent corrosion, add a lot so that maintenance is less frequent. A little bit will just be enough to let your guard down. But I am not sure you have to. Is that really brass? Is it heavily chrome plated? or is it stainless steel?