ELEV-8 landing gear improvements by our machinist Kenneth Glass

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Hey all,

Improvements to products happen all the time, in every company. Our staff enjoy seeing customers that are happy with what they receive from Parallax. They continue to raise the bar on quality, on their own. They thrive on customer feedback and punish themselves if a product fails in the field, even if they should really roast an engineer.

I'd like to recognize what our Machinist Kenneth Glass is doing to improve our ELEV-8 landing gear. Great products are often made in small steps, even if they're multi-year R&D efforts. More than the landing gear itself, I think efforts from Kenneth should be visible on the outside.

Until recently, our ELEV-8 landing gear was made from acetal copolymer (trade name Delrin) on a laser cutter. This produced a rigid landing gear that still broke on certain impact (when Kevin Cook crashes). Although very functional, the landing gear didn't look too "finished" because the laser would melt the material and produce rough edges.

With some help from Matt Huntzinger and the ELEV-8 team of Nick and Kevin, Kenneth took it upon himself to improve the ELEV-8 landing gear. He moved the process to our CNC router with HDPE. The results of the new landing gear are impressive:

While he started at Parallax as a CNC operator, he's now effective at taking drawings to prototype and production, with all the toolpaths, fixtures and processes in between.

Way to go, Kenneth!

Ken Gracey

Kenneth will show you how to run the router if you want to learn.

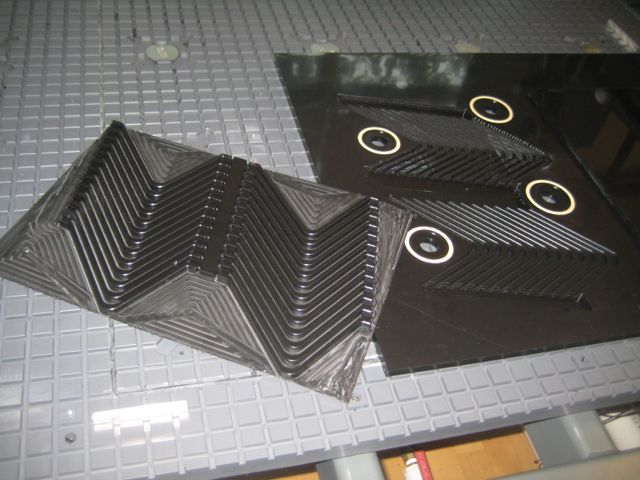

ELEV-8 Landing Gear with the new version on the table.

Close-up of improved finish on old and new landing gear

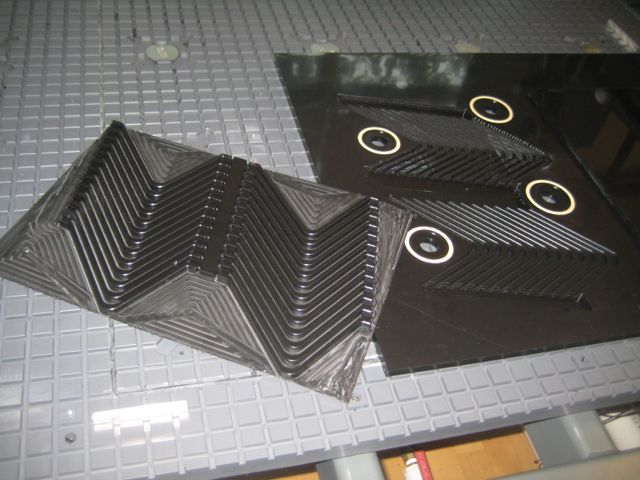

Load material, press a button and harvest 26 pieces at a time

Vacuum table fixture shows openings to hold down plate for second operation chamfer on bottom side.

Improvements to products happen all the time, in every company. Our staff enjoy seeing customers that are happy with what they receive from Parallax. They continue to raise the bar on quality, on their own. They thrive on customer feedback and punish themselves if a product fails in the field, even if they should really roast an engineer.

I'd like to recognize what our Machinist Kenneth Glass is doing to improve our ELEV-8 landing gear. Great products are often made in small steps, even if they're multi-year R&D efforts. More than the landing gear itself, I think efforts from Kenneth should be visible on the outside.

Until recently, our ELEV-8 landing gear was made from acetal copolymer (trade name Delrin) on a laser cutter. This produced a rigid landing gear that still broke on certain impact (when Kevin Cook crashes). Although very functional, the landing gear didn't look too "finished" because the laser would melt the material and produce rough edges.

With some help from Matt Huntzinger and the ELEV-8 team of Nick and Kevin, Kenneth took it upon himself to improve the ELEV-8 landing gear. He moved the process to our CNC router with HDPE. The results of the new landing gear are impressive:

- Run time on CNC router may be about the same as the laser cutter

- Quality of product just increased substantially

- Smooth, machined edges with a chamfer on both sides in a two-step operation

- Vacuum-hold down fixture for both operations

- More flexible HDPE material doesn't snap nearly as easily as acetal co-polymer

- Uses scrap HDPE from Eddie robot manufacturing (yeah!)

While he started at Parallax as a CNC operator, he's now effective at taking drawings to prototype and production, with all the toolpaths, fixtures and processes in between.

Way to go, Kenneth!

Ken Gracey

Kenneth will show you how to run the router if you want to learn.

ELEV-8 Landing Gear with the new version on the table.

Close-up of improved finish on old and new landing gear

Load material, press a button and harvest 26 pieces at a time

Vacuum table fixture shows openings to hold down plate for second operation chamfer on bottom side.

Comments

-Phil

Brilliant!!

ELEV-8 Landing Gear 4-Pack: http://www.parallax.com/tabid/964/ProductID/841/Default.aspx