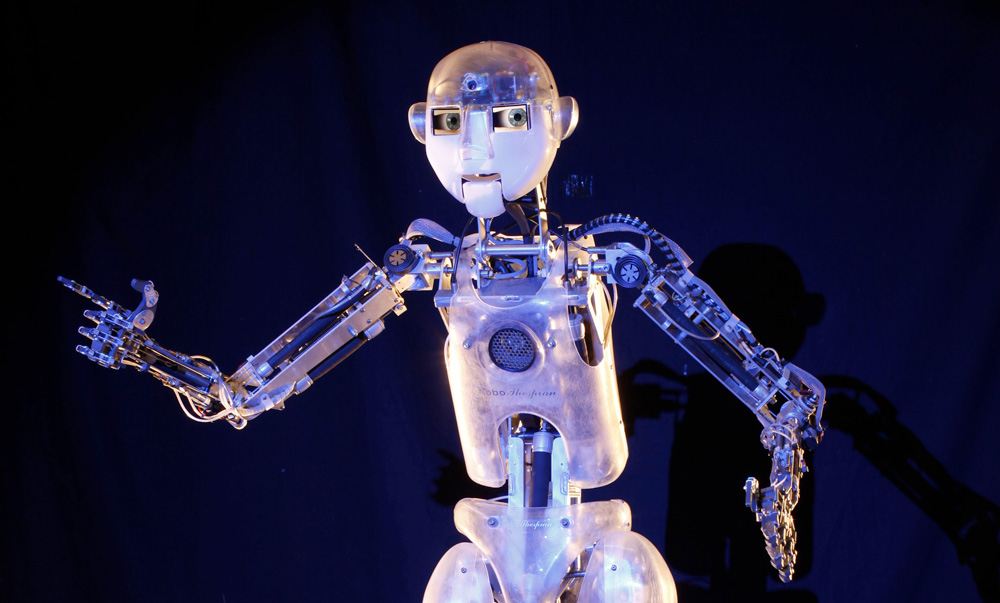

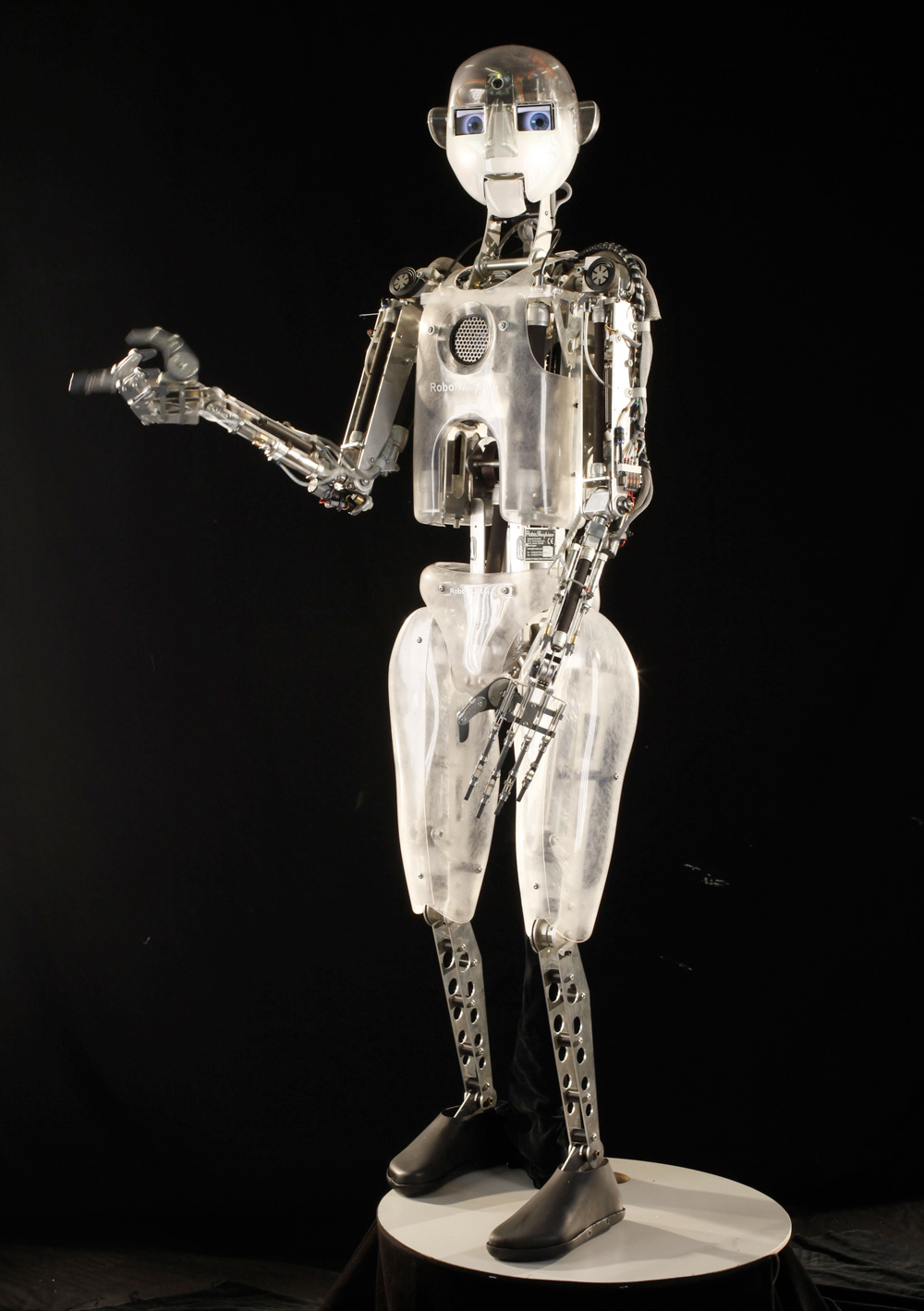

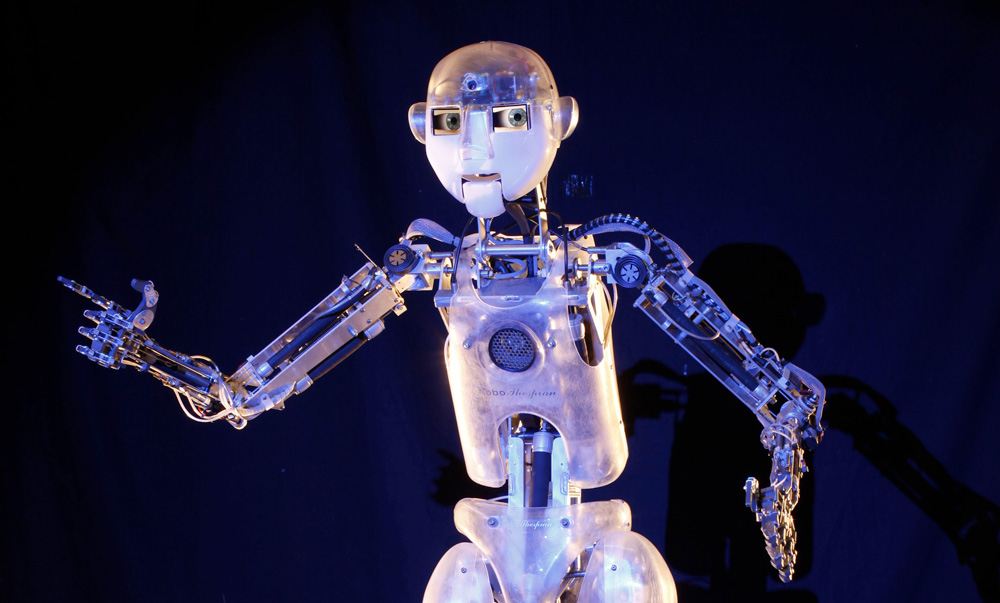

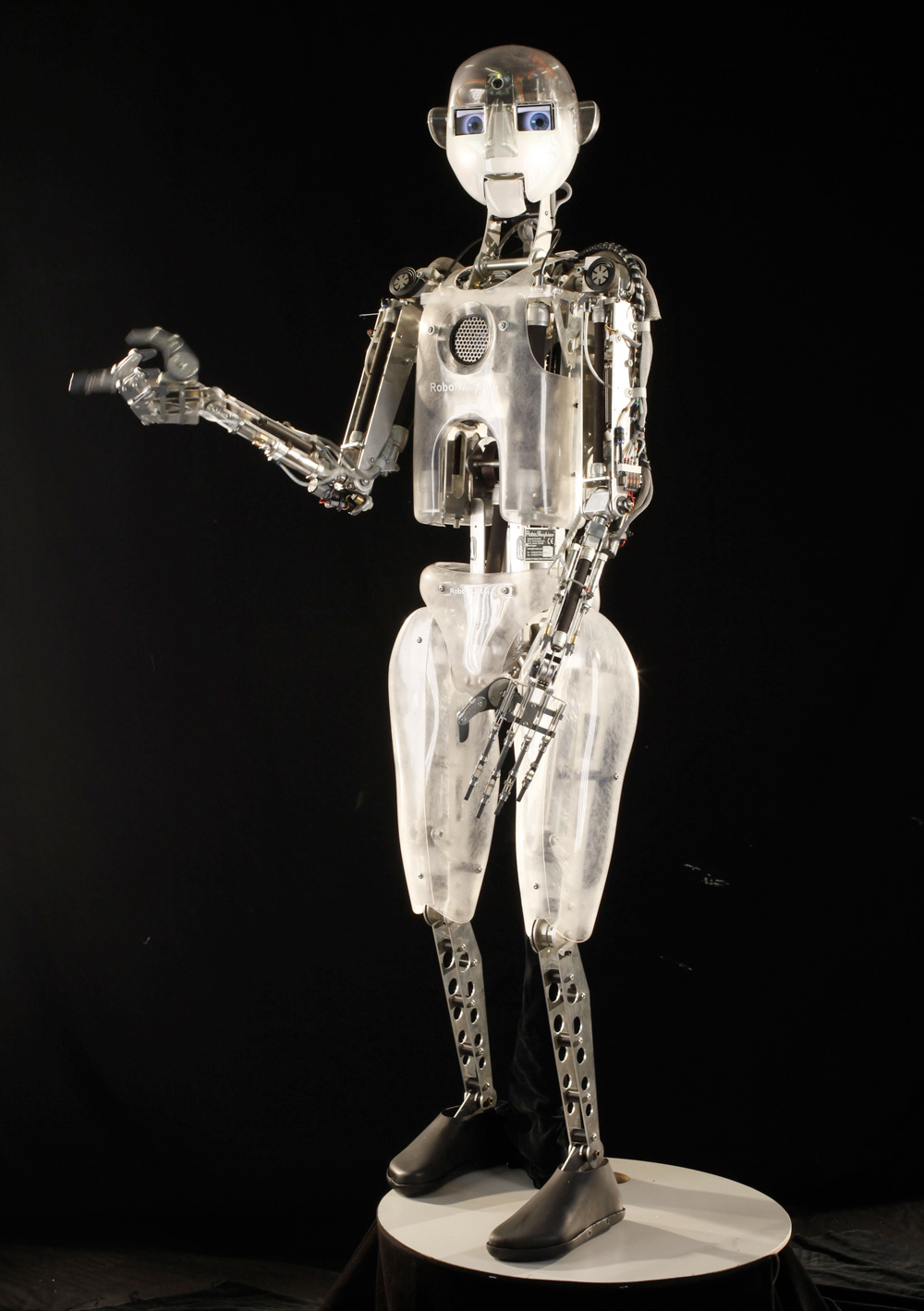

RoboThespian (tm)

This project was submitted to Parallax by Will Jackson.

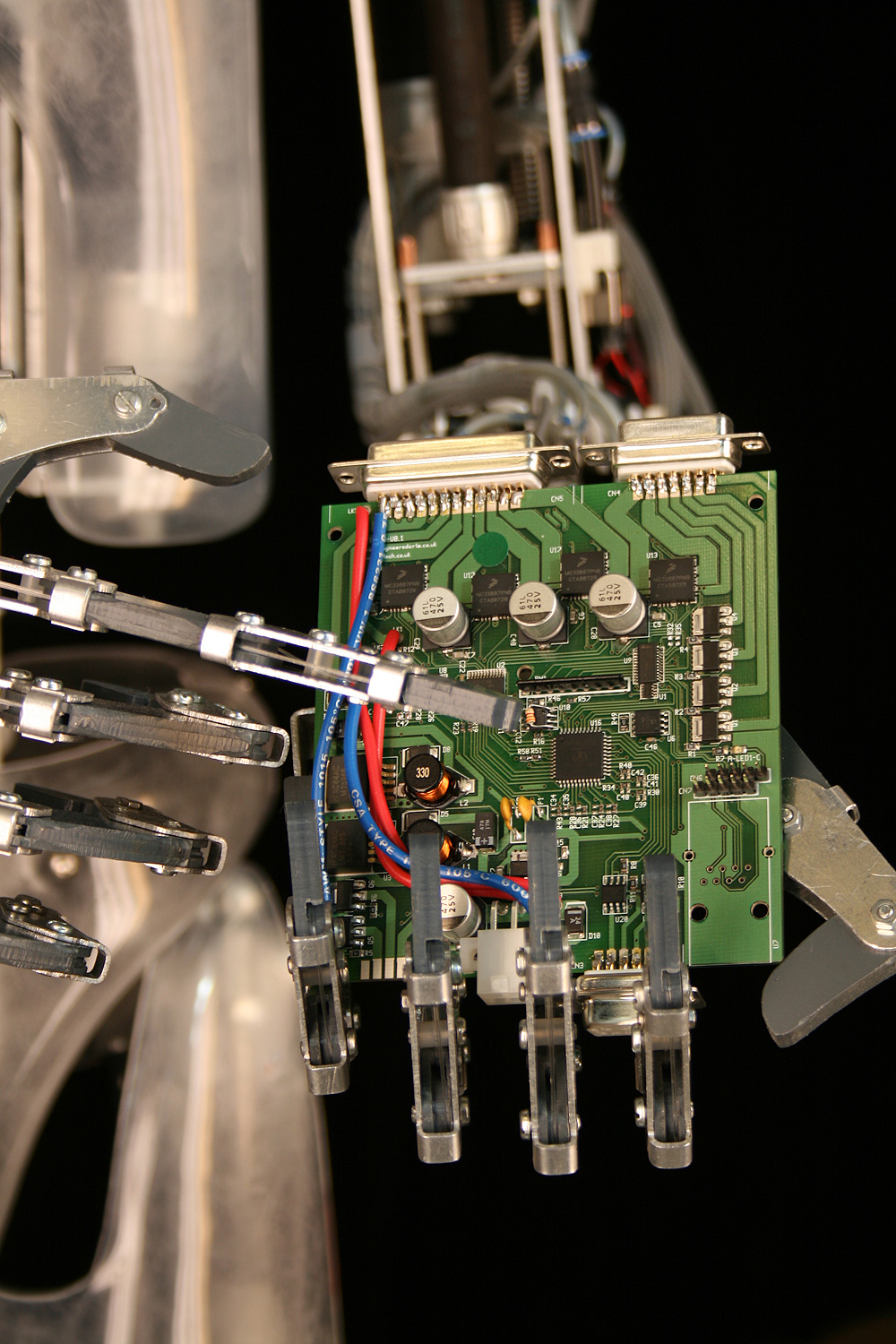

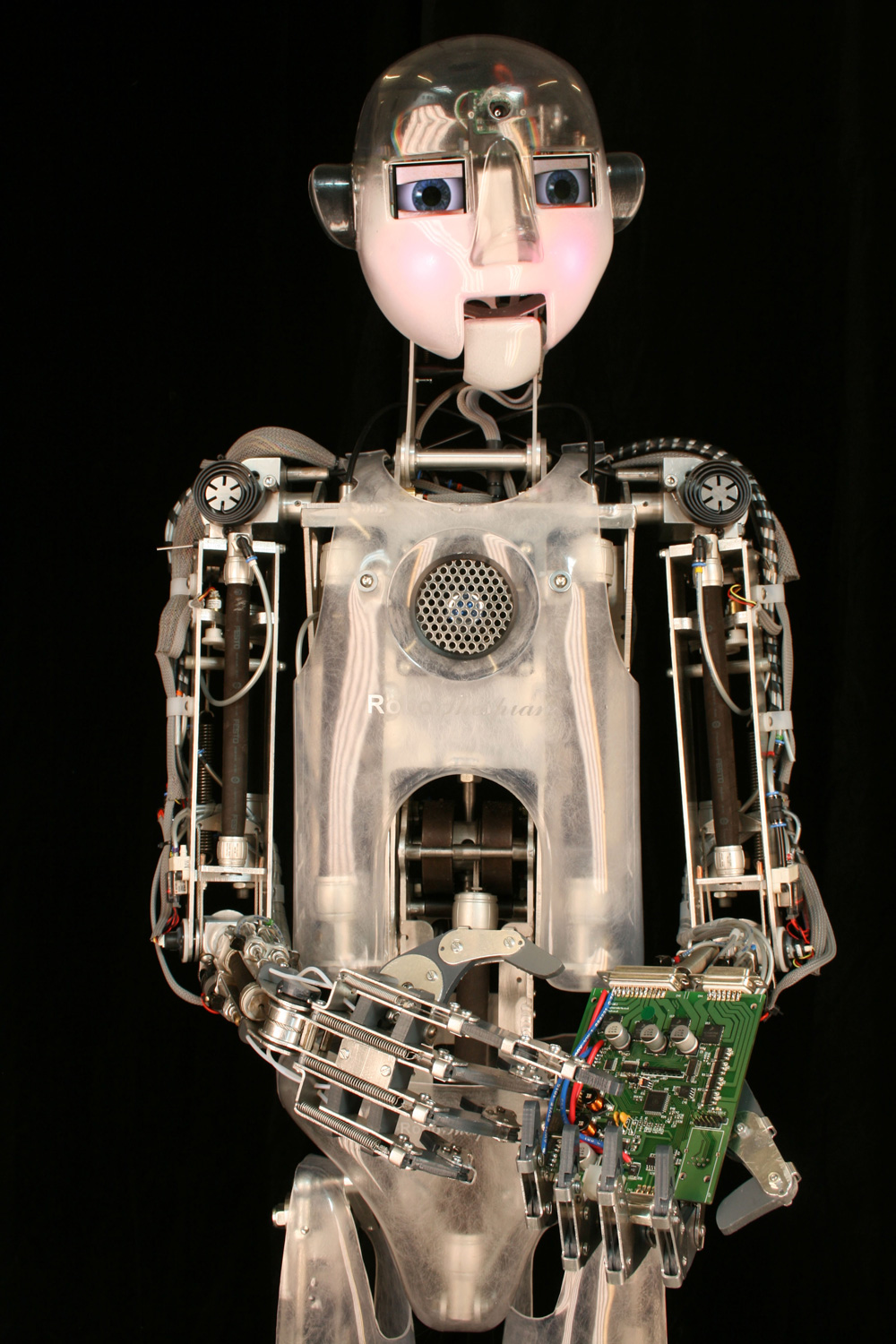

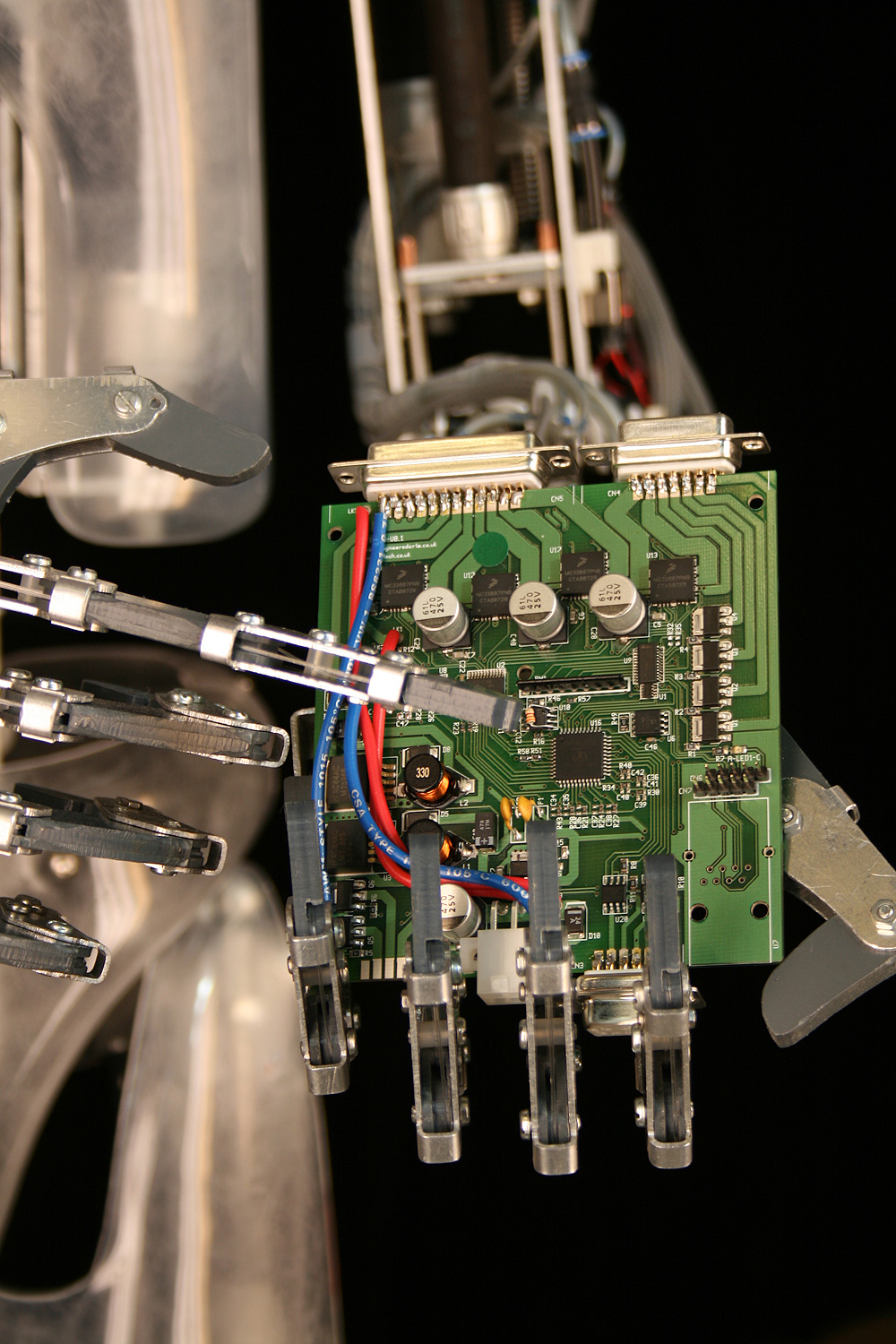

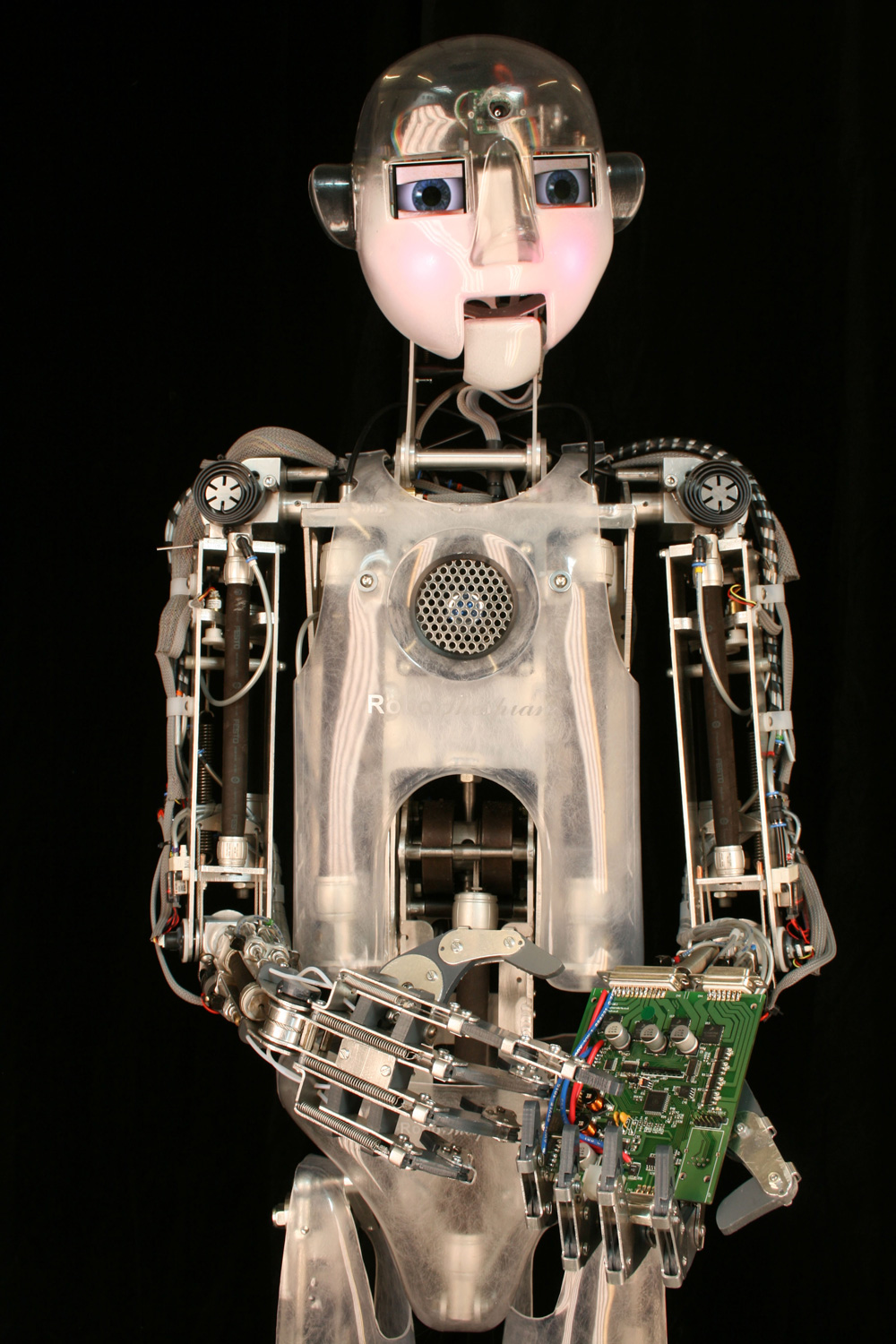

RoboThespian is fully programmable with a web based interface and the API is available to developers. The seventeen major axis are all controlled using a custom written PID algorithm that features optimisations for air muscle control and adapts in real time to cope with cross axis dependencies, ie the load and dynamics of the upper arm vary according to the position of the fore arm and hand. All of this requires a lot of processing power and fast communication. We choose Propeller because it fits the application so well with cogs dedicated to various functions able to communicate quickly. The Propeller chip is used in the motion control boards, controlling 9 axis with PID and complex cross axis feed forward with each Propeller chip. There are two motion boards in each model 2 RoboThespian.

The cost to performance ratio is incredible. We were also impressed by Chip Gracey's design approach to Propeller - We trust the silicon because we know the dedication and passion that went into the design of it.

Software and Hardware Design - We plan to release all our software in a year. Our core piece of software, (running on PC not Propeller), is called IOServe it runs under Linux and provides a generic way to link and program all robot hardware, it also has the ability to capture motion data and replay it and modify existing motion sequences on the fly, including an interface to the open source 3D program Blender where you can create virtual robots to control real hardware. This will be a powerful tool for any robot builder.

Additional Resources:

RoboThespian is fully programmable with a web based interface and the API is available to developers. The seventeen major axis are all controlled using a custom written PID algorithm that features optimisations for air muscle control and adapts in real time to cope with cross axis dependencies, ie the load and dynamics of the upper arm vary according to the position of the fore arm and hand. All of this requires a lot of processing power and fast communication. We choose Propeller because it fits the application so well with cogs dedicated to various functions able to communicate quickly. The Propeller chip is used in the motion control boards, controlling 9 axis with PID and complex cross axis feed forward with each Propeller chip. There are two motion boards in each model 2 RoboThespian.

The cost to performance ratio is incredible. We were also impressed by Chip Gracey's design approach to Propeller - We trust the silicon because we know the dedication and passion that went into the design of it.

Software and Hardware Design - We plan to release all our software in a year. Our core piece of software, (running on PC not Propeller), is called IOServe it runs under Linux and provides a generic way to link and program all robot hardware, it also has the ability to capture motion data and replay it and modify existing motion sequences on the fly, including an interface to the open source 3D program Blender where you can create virtual robots to control real hardware. This will be a powerful tool for any robot builder.

Additional Resources:

- RoboThespian web site

- Must See! YouTube movie with robot

- Andy Android RoboThespian at the Carnegie Science Centre RobotWorld in Pittsburg

- Contact Will Jackson

Comments

We need a more intimidating avatar to keep the troops in line!

What's next? A sponge?