So I got this Maker Bot...very cool, warrants a Propeller!

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Hey all,

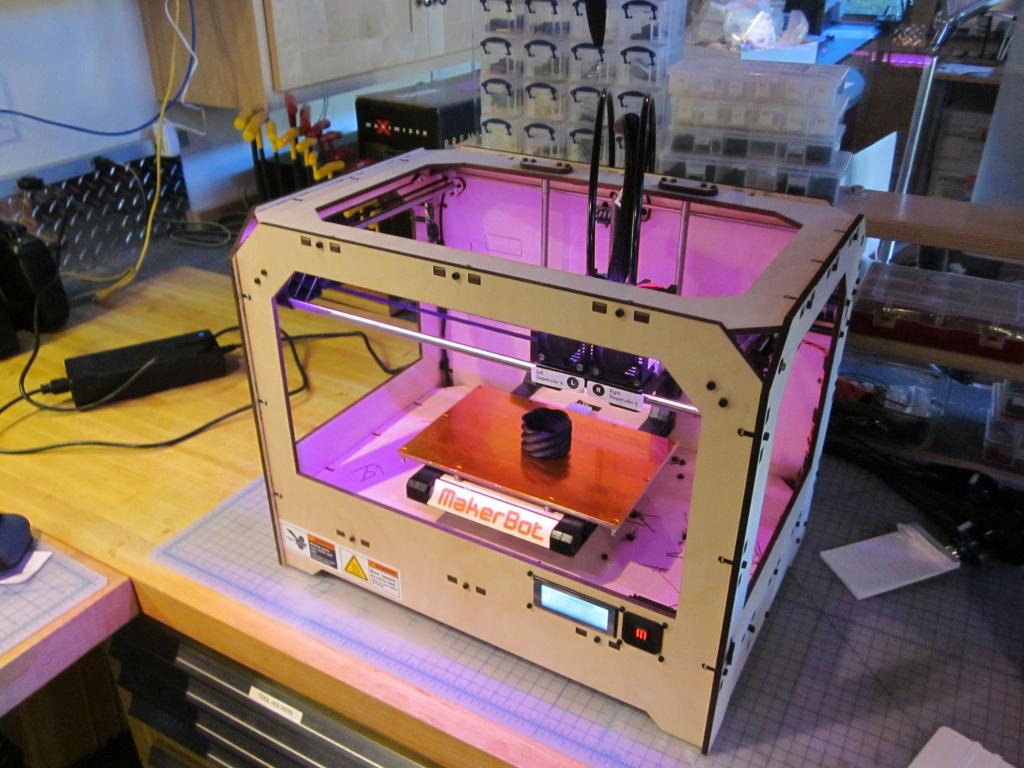

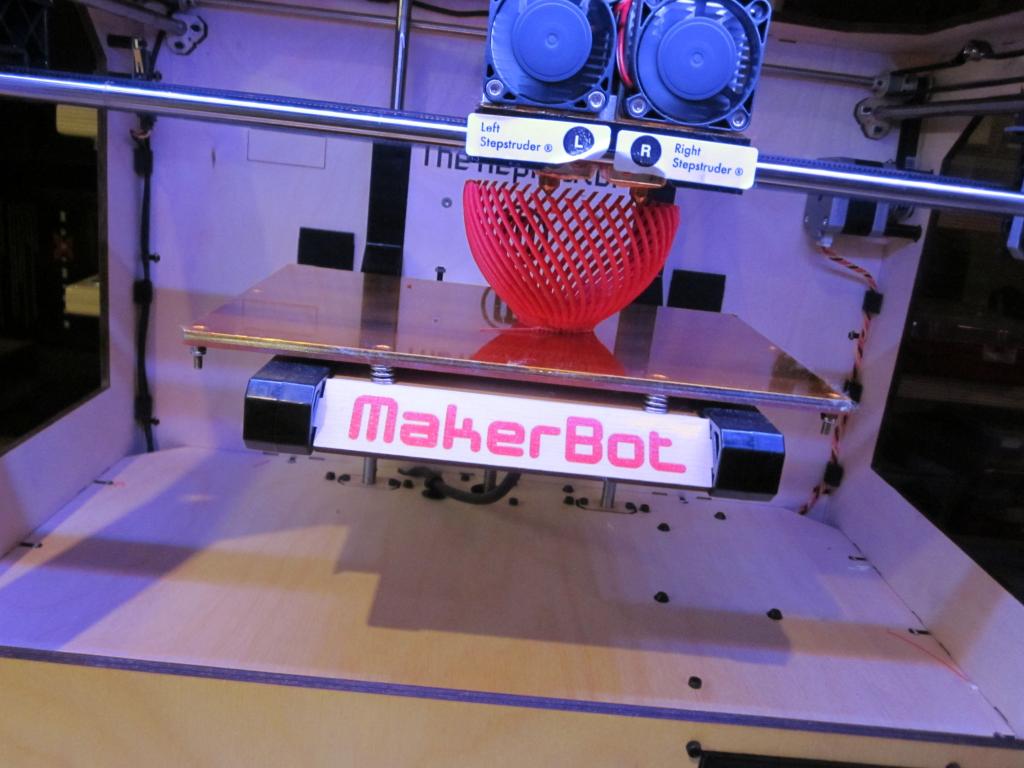

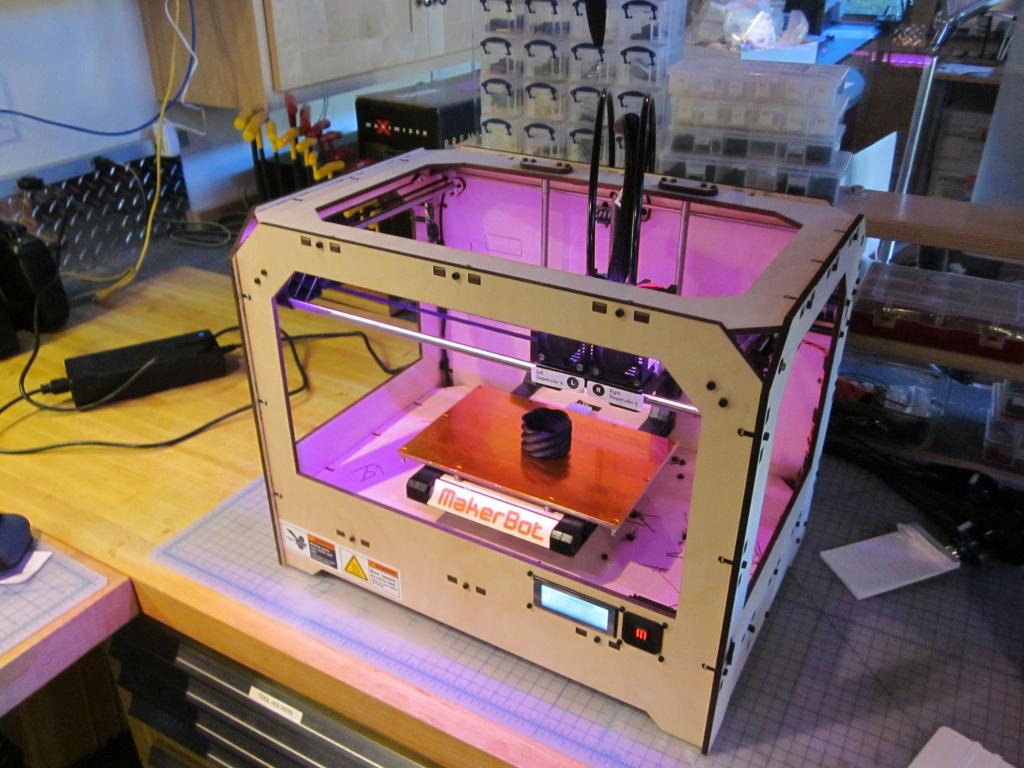

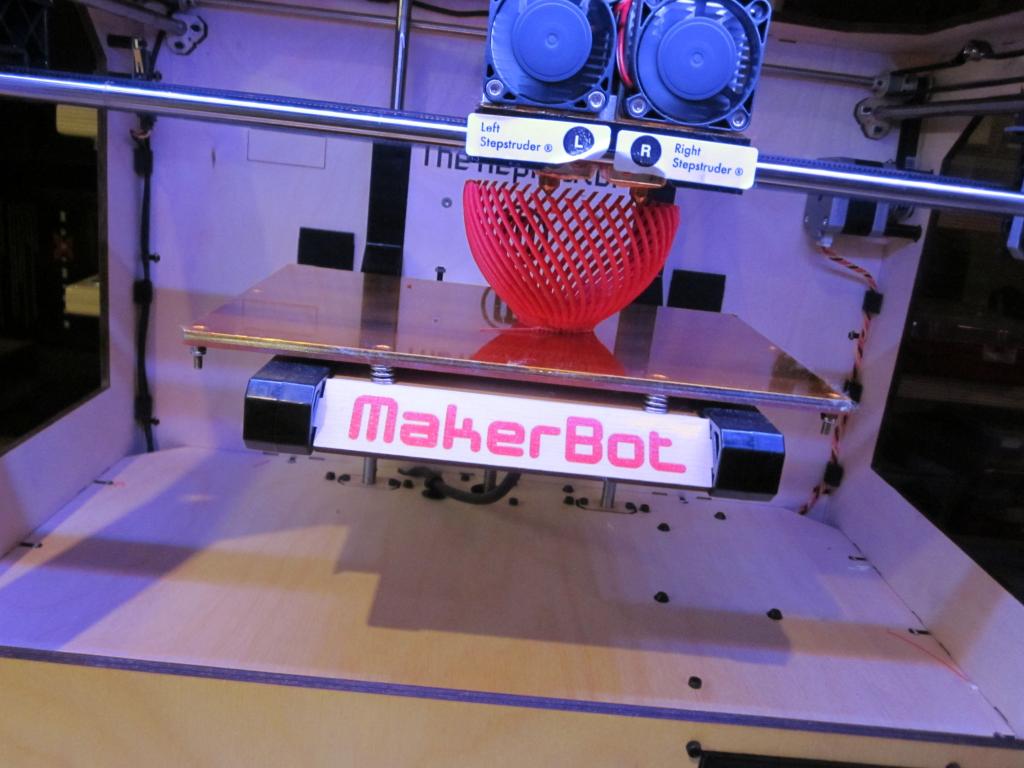

Seen lots of discussion around here about 3D printing so I finally brokered an ELEV-8 hardware (plus some other cool stuff) trade somewhere for a Replicator. Having lots of experience with the reverse process of milling, at first look I can really appreciate the ability to make parts that can't even be milled [easily, without 4th and 5th axis] and to get the job done quickly without fixturing headaches. I'm using 1.8mm ABS and certainly experienced some startup issues with nozzle trouble, bed heating issues to hold the part, etc. None of this was a big deal and I think it's mostly behind me but it certainly owned a few evenings.

And wow, does this device warrant a Propeller! It's great how it runs files from an SD card and that it isn't saddled with a PC. The LCD works fine for basic stuff, but imagine how a Propeller could improve the product. Think about a slick video display with a mouse for navigation. The user interface could be really efficient, easy, and visual by showing the navigation structure and monitor all together. And of course with the Propeller it could talk to you.

I've got a project in mind for MakerBot as soon as I figure out how to get Sketchup to do what I want to do, drawing a nose cone for 4" ABS pipe. I know it's a trivial effort, but I haven't had the time to sit down and do this yet. Instead I've suffered berating comments from my kids who are running circles around me with Thingiverse files. Below you can see a couple of recent parts we printed.

Both Nick and Kevin have these machines at Parallax, but they have the PrintrBot model from Brook http://printrbot.com, another successful KickStarter project. Great for prototyping.

I'm interested in learning what others are doing with their 3D printers. Are you using them, or are they sitting idle? Have you solved any little (or big) problems with them?

Ken Gracey

Seen lots of discussion around here about 3D printing so I finally brokered an ELEV-8 hardware (plus some other cool stuff) trade somewhere for a Replicator. Having lots of experience with the reverse process of milling, at first look I can really appreciate the ability to make parts that can't even be milled [easily, without 4th and 5th axis] and to get the job done quickly without fixturing headaches. I'm using 1.8mm ABS and certainly experienced some startup issues with nozzle trouble, bed heating issues to hold the part, etc. None of this was a big deal and I think it's mostly behind me but it certainly owned a few evenings.

And wow, does this device warrant a Propeller! It's great how it runs files from an SD card and that it isn't saddled with a PC. The LCD works fine for basic stuff, but imagine how a Propeller could improve the product. Think about a slick video display with a mouse for navigation. The user interface could be really efficient, easy, and visual by showing the navigation structure and monitor all together. And of course with the Propeller it could talk to you.

I've got a project in mind for MakerBot as soon as I figure out how to get Sketchup to do what I want to do, drawing a nose cone for 4" ABS pipe. I know it's a trivial effort, but I haven't had the time to sit down and do this yet. Instead I've suffered berating comments from my kids who are running circles around me with Thingiverse files. Below you can see a couple of recent parts we printed.

Both Nick and Kevin have these machines at Parallax, but they have the PrintrBot model from Brook http://printrbot.com, another successful KickStarter project. Great for prototyping.

I'm interested in learning what others are doing with their 3D printers. Are you using them, or are they sitting idle? Have you solved any little (or big) problems with them?

Ken Gracey

Comments

View - Tool Palettes - Large Tool Set

Draw the shape that you want to revolve, make sure that it is a face. Then draw a circle to serve as the path that the face will "follow". The size of the circle is irrelevant. I usually draw it large enough so that it won't intersect any part of the model. Also set the number of segments in the circle to a number that makes it smooth enough for your needs. If you want it to be a smooth as possible when printing, set the number of segments equal to the circumference of the part in millimeters. It is very important that the center of this circle lie on the same plane as the face that will be revolved and on the axis of rotation. The circle is of course perpendicular to the axis of rotation that you want.

Here's the trick to using the follow me tool. Select the circle first, then click on the Follow Me tool, then click once on the face that you want to revolve. That's it.

To be more on topic - Yes! Absolutely, I wish that there was a Propeller solution to running the MakerBot. It could be so much better. Mine has sat idle from time to time, but not for long. I just used it last night to make some robot parts. Last week I used it to make a part to fix my outboard motor.

Your application sounds great, though - small parts for R/C stuff and robots seems like the ideal fit. I'll want to build some prototype parts that we may put into the CNC mill with aluminum, and to make some parts for personal projects like the GPS boat.

There's a whole lot of excitement around these printers right now. Just today I heard a story on NPR's "Science Friday" about how some scientists are printing with live cells, making small pieces of organs, and then putting them into people where they grow on their own [hopefully]. I realize I condensed tons of research into a single statement, but there's a lot of applications here that haven't been fully identified. Thingiverse certainly shows what's going on at least with ABS and PLA. http://www.sciencefriday.com/segment/06/22/2012/can-3d-printers-reshape-the-world.html seems to be the story, though I heard it today (and not last June).

Should be a lot of fun.

@Rich: this is in the Replicator G software?

'So glad to hear you got your Replicator working! I know you'll have a lot of fun with it.

Despite the sheer fun of making stuff with it, my MakerBot sits mostly idle, I'm sorry to say. I've made two useful items with it: a set of extensions for a bike rack and a tool for installing lenses in the TSL1401-DB modules. Having said that, however, I have no complaints about its performance, especially after Rich (W9GFO) sent me his very sturdy MakerBot-produced extruder. But, by comparison, the Epilog laser cutter I purchased prior to the MakerBot is by far the more useful -- and productive -- shop tool.

-Phil

No that's in SketchUp.

I think the kids in my robot class will really like this tool. I'll give them the challenge of drawing a part and making it on the Replicator.

Thanks Rich, that'll be a time saver. I'll try it right now.

-Phil

I really like it.

The author has been seen around in the prop area (maybe F32 rings a bell?), and in the kisslicer forum there is also a bleeding edge alpha.

I uploaded a propeller platform "x" support but my parts disappeared. Have to upload them again.

Massimo

I have a prusa v2 partially assembled. Only need the time for the jhead and electronics.

I have done prototype pcbs to use a prop and the existing pololu drivers although I did my own driver pcb based on the A4982/4 IIRC (tssop28) too.

Just have not had the time to continue (just like the quadcopter) - both half finished.

Hopefully that should change in a week or so time.

I've been using the PE (~$99) Alibre for the CAD software and it works well enough for what I need and my laptop can handle. You can even try their full version for 30 days.

A lot of talented people are removing their creations from that site these days.

If you want something from that site, download it NOW, it may not be available for much longer.

These guys patented a bit of add-on hardware, a pneumatic table to increase production. So everyone gets in a huff about them not being loyal to 'open source'.

What I really love about the 3D printing is the rather sophisticated open source software. It seems to me that restricting people to not having patents for hardware is rather idealistic and simple greed from those that want everything that they can get for free.

In other words, it is a shame. We all have to eat. There are good reasons for getting a patent. It just is not the same as shutting people out of learning computers with pricy software.