Sealing airflow to fans when not in use

Hey guys,

I have a quick question about a design. In this apparatus we have a heated chamber. We want to cool it very quickly. The idea is to cut off the heat source and turn on some fans for a few seconds. (We used a similar design in a current apparatus and it worked well). However, we want also want the apparatus to be well insulated, and one concern is loss of heat through inactive fans. A solution is to cover the fans when they are not in use.

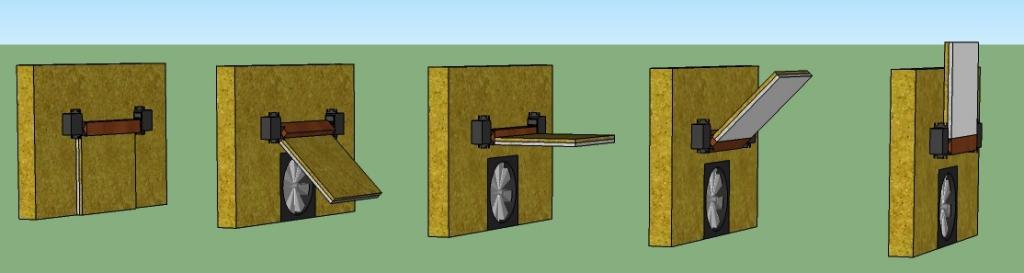

The current idea is to have a servo open and close a door to the fan. This way the area is sealed when the fan is not in use. A crude model of the concept is attached. It's a simple matter of attaching servos to a door, but I was wondering if there was a better way.

The rotating mechanism does take up a bit of space, but any linear actuators I've seen have been extremely expensive. Does anybody have any other suggestions? I've been thinking about this for a while and this is the best mechanism I have come up with.

Any thoughts are appreciated.

I have a quick question about a design. In this apparatus we have a heated chamber. We want to cool it very quickly. The idea is to cut off the heat source and turn on some fans for a few seconds. (We used a similar design in a current apparatus and it worked well). However, we want also want the apparatus to be well insulated, and one concern is loss of heat through inactive fans. A solution is to cover the fans when they are not in use.

The current idea is to have a servo open and close a door to the fan. This way the area is sealed when the fan is not in use. A crude model of the concept is attached. It's a simple matter of attaching servos to a door, but I was wondering if there was a better way.

The rotating mechanism does take up a bit of space, but any linear actuators I've seen have been extremely expensive. Does anybody have any other suggestions? I've been thinking about this for a while and this is the best mechanism I have come up with.

Any thoughts are appreciated.

Comments

Or forget the grating thing and just have the door slide into position rather than flipping up.

It looks like the door would be small enough to accomidate a lifting which, such as this:

http://www.servocity.com/html/hs-785hb_3_5_rotations.html

Jim

There are louvers that will open when the fans are running and close when they are not.

Bruce

Edit: Or just make a baffle with a pin going through the center. Make one half of the baffle just slightly heavier than the other, but also make the baffle light enough so that the air pressure from the fans will open them.

Louvers? Sorry I don't see them. Just see a door to go up and down.

Jim

Jim

Go to Home Depot and open up a bathroom fan, and you will get the idea.

Bruce

Gotha. I though you saw a louver in the OP's design.

Yes, standard attic fan setup.

Jim

My bad... I believe the terminology would be backdraft dampners. http://www.grainger.com/Grainger/backdraft-roof-dampers/ventilation/hvac-and-refrigeration/ecatalog/N-jz2?Ndr=basedimid10071&sst=subset

I was thinking Jim was the OP. Should have paid better attention.

Interesting idea, but I don't think this would work for our application. We actually will have a fan (or set of fans) on each side. One to suck hot air out, another to push room-temperature-air or cool-air in. We could not rely on pressure to open the door leading to the cool-air intake fan.

We are essentially studying what kinds of temperatures animals prefer, so we don't want any moving parts on the inside of the apparatus with the animal.

Initially, I wanted to have a moving door so that I could attach some insulation to the inside of the door. However, some sort of sliding grate would work as well. I don't think I should expect a huge temperature loss through uninsulated sealed fans.

I don't follow your concern. Can you elaborate?

I investigated louvers a bit, but I have not seen any smaller inexpensive adjustable louvers that can be controlled electronically. I was not aware of the term "backdraft damper," this produced a lot better results, but some of these may be too large. I'll keep looking.

I appreciate the thoughts so far.

I can see now what you are trying to do. Rotate the door 180 degrees. I thought you were trying to lift it vertically, that's why I suggested a winch servo at the center top to lift the door.

Jim

I thought the same thing. I think my working on the motorized sliding pot made me jump to that conclusion.

One you point out it rotates, the rotation looks obvious from the drawings.

It actually doesn't matter to me how it works, the model was just of the current concept. My colleague have now requested the covers be insulated as well, so there goes using comercial dampers or louvers.

Those motorized slide potentiometers are pretty sick for what they are. I would be a little concerned with strength if they were moving an object vertically, but I think they might work pretty well for horizontal movement.

In our current version of the apparatus and experiment, other research suggested that 40 c (95 f) is uncomfortable but "sublethal" to our species. Our subjects started getting uncomfortable at around 34-37c body temperature (measured from infrared thermometer directly on the body surface) or 50 c air temperature. The discrepancies in this temperature is one of the big reasons we are rebuilding the apparatus and trying to seal and insulating it well. We hope to essentially build a "forced air incubator" that doesn't have much of a temperature gradient. This way any air temperature measurement will be closer to the temperature of the animal.

Aside from that all we could do to increase the accuracy is to install thermometers inside the animals, and I really don't want to do that. Anything invasive is not my style. We just want our animals to be happy and do their normal thing as unhindered as possible.

-Phil

When I attempted some humdity control experiments, I was surprised how much the relative humidity changed with relatively small changes in temperature.

That's a very good point, Duane, especially considering what the original poster stated about skin temperature, etc. And controlling the humidity might be very difficult if your space is small and you have lots of items inside it that can change the humidity in unpredictable ways - respiration of organisms, open water sources whose surface area changes, or fur or cloth, etc. that get wet. When you're operating near body temperature, I suppose the only way for the critter to keep cool is to sweat or swim in a pool, so things can get complicated if you don't consider those variables.

My input is to use a solenoid to push/pull a door and you can use overlapping slots on the door and chassis (as mentioned earlier) for minimal movement.

Last time, we recorded both temperature and humidity with a separate device from the one controlling our experiment (not a propeller). This time we are using a propeller and a sensirion temperature/humidity sensor. It seems like humidity was pretty proportional to temperature. I didn't look at the humidity graphs all that much though.

But now that you guys mention it. It would be interesting to do an experiment where temperature changes but humidity stays consistent. Wow that sounds like a pain to set up.

In my experience, it's a huge pain to maintain a certain relative humidity.