My new Toy a Cold Saw

Well I went on a bit of a spending spree and invested into my company with some new toys (TOOLS). The first is a Cold Saw. I also bought a few other tools, but I'll describe them later after I get them up and running.

I have used a 14" Chop Saw for years to cut metal bars, tubes and rods. I've always just accepted that after the cut, you need to take the part to a grinder and clean it up.

I have seen some TV shows saying how nice a Cold Saw is at cutting metal. Well, until you actually use one, you can't really appreciate how much of a difference it makes.

Cold Saws can get pretty pricey. Ive seen some upwards of $12K. I got a pretty cheap one @ $800. Its not as fancy as the more expensive ones, but for what Im doing its great.

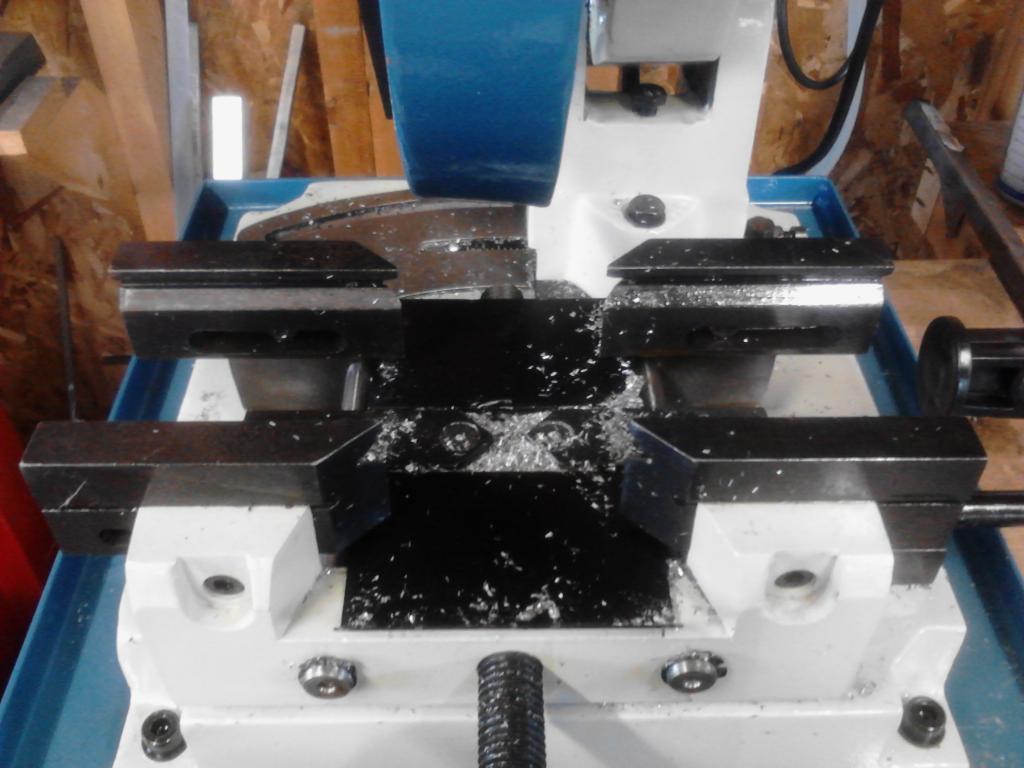

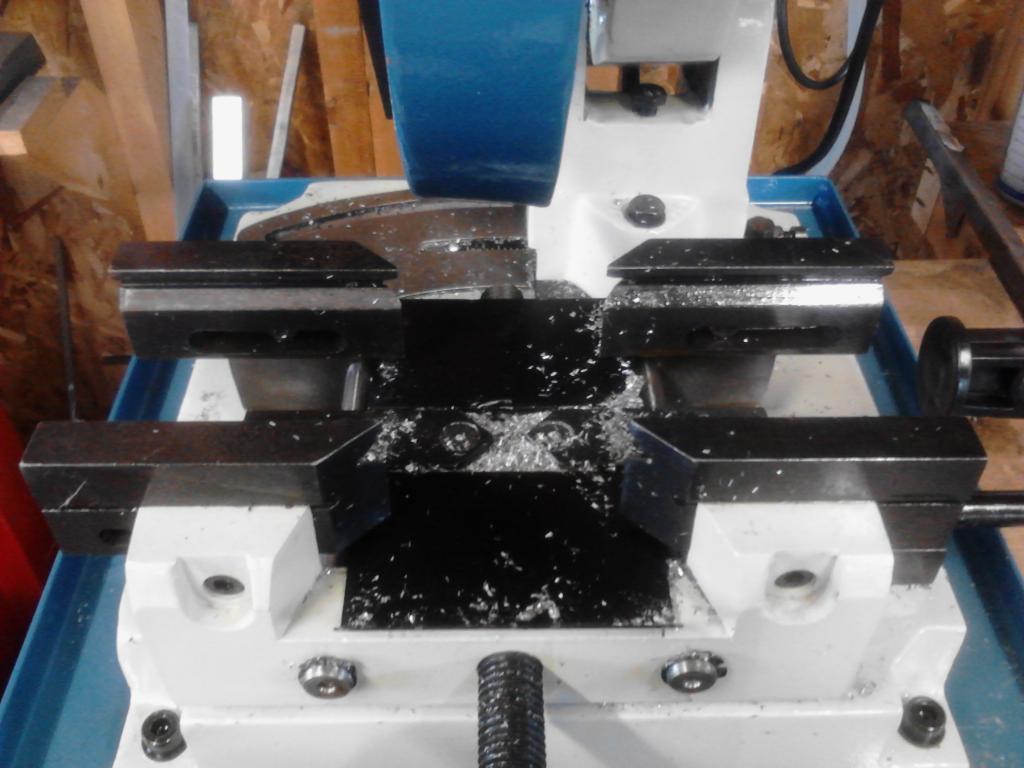

Ive included some pictures. The square piece of aluminum was cut on a ~$200 cheap band saw I got at HarborFreight last year. As you can see it doesnt even cut straight. The blade flexes. I have the saw as tight and the guides as close to the metal as I could get it. This is the kind of cut I got. The other cut on the other side was done with the new cold saw. Notice how straight it is and this picture is how the metal was after the cut, without any cleanup work being done.

The other pictures show a piece of 1/8 x 1 bar stock. As you can see in the one photo the metal gets melted and smears. This will need to be cleaned up on a grinder. Notice on the other picture, this is directly after a cut on the cold saw, with NO cleanup done, or needed. Unless, of course, you want to bevel the edges.

I guess, it all boils down to , You get what you pay for.

Here is a video of the saw I got... http://www.youtube.com/watch?v=yJz41jv_-Xg

I have used a 14" Chop Saw for years to cut metal bars, tubes and rods. I've always just accepted that after the cut, you need to take the part to a grinder and clean it up.

I have seen some TV shows saying how nice a Cold Saw is at cutting metal. Well, until you actually use one, you can't really appreciate how much of a difference it makes.

Cold Saws can get pretty pricey. Ive seen some upwards of $12K. I got a pretty cheap one @ $800. Its not as fancy as the more expensive ones, but for what Im doing its great.

Ive included some pictures. The square piece of aluminum was cut on a ~$200 cheap band saw I got at HarborFreight last year. As you can see it doesnt even cut straight. The blade flexes. I have the saw as tight and the guides as close to the metal as I could get it. This is the kind of cut I got. The other cut on the other side was done with the new cold saw. Notice how straight it is and this picture is how the metal was after the cut, without any cleanup work being done.

The other pictures show a piece of 1/8 x 1 bar stock. As you can see in the one photo the metal gets melted and smears. This will need to be cleaned up on a grinder. Notice on the other picture, this is directly after a cut on the cold saw, with NO cleanup done, or needed. Unless, of course, you want to bevel the edges.

I guess, it all boils down to , You get what you pay for.

Here is a video of the saw I got... http://www.youtube.com/watch?v=yJz41jv_-Xg

Comments

I never heard of a cold saw or seen one operate like that. What kind of blade does it use? A diamond blade?

Bruce

http://en.wikipedia.org/wiki/Cold_saw

I'm not 100% sure. I know the blades last a lot longer because they do not overheat like most blades would. A chop saw really is not cutting the metal as much as its melting. Don't get me wrong chop saws are most popular because they are cheap and work pretty good. One down side is they produce a ton of metal dust.

I know there are different kinds of blades for different metals. I will probably just stick with the one it came with because the blades are well over $100 each. I guess having you old blades sharpened is a good idea when the new ones cost so much.

Bruce