Any experts on gears?

I need to do a 2:1 ratio gear, probably out of Delrin or hi durometer rubber, 1/2" stock. I have a fixed dimension for the shaft centers of 2.125", using 12mm shafts.

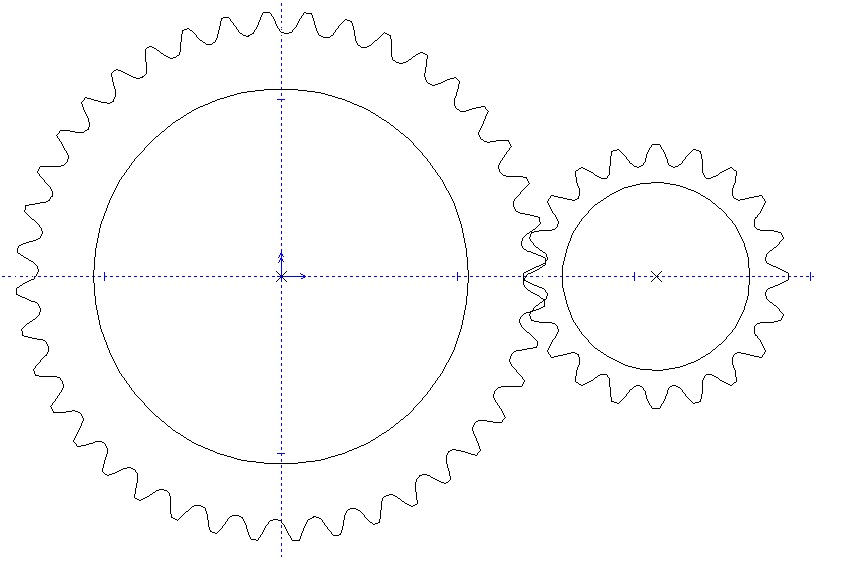

So the gears must be such that one gear has twice as many teeth. I have a program called Bobcad that has a gear creator, but it expects you to know something about how to use it for the specific role. I want to make the teeth fit each other, and have only experimented an hour or so and you can see what I am up against. I have looked online and cannot find a calculator that would output the pitch diameter, outer diameter, root diameter etc for this purpose of a gear box. If anyone has done something like this I could use some advice on how to calculate it.

So the gears must be such that one gear has twice as many teeth. I have a program called Bobcad that has a gear creator, but it expects you to know something about how to use it for the specific role. I want to make the teeth fit each other, and have only experimented an hour or so and you can see what I am up against. I have looked online and cannot find a calculator that would output the pitch diameter, outer diameter, root diameter etc for this purpose of a gear box. If anyone has done something like this I could use some advice on how to calculate it.

Comments

-Phil

Is 2.125 for the shaft centers and locked number?

servocity.com

has gears.

I just purchased the gear generator - by far, the best $26 I've ever spent:

http://woodgears.ca/gear/

Also, consider watching the videos about the gear generator software - very impressive:

http://woodgears.ca/gear/video.html

Google dxf gear calculators.

How profound, and subtle -- makes sense

No, this doesn't seem to be the case.

Perhaps this does not apply to ratios of 2:1, but may in other cases where phase shift could occur, in which the same teeth did not make the same contact each revolution.

But on a 2:1 ratio, that's not going to happen.

But what if my design can tolerate a slight error in ratio? Say I build my 2:1 gear box from 41 and 20 tooth gears. Then every tooth on one gear is going to meet every tooth on the other gear at some point and the wear is then evened out.

-Phil

Since the application is likely to be low power, it may not matter much at all. And it is far easier to get what you want by a 2 to 1 ration than something like 13 to 7.

A 12/24 pairing will have the same tooth of the small gear always contacting the same two places on the big gear. A 13/24 pairing will have the tooth of the small gear "walking" its way around all of the teeth of the big gear - I think. I'm sure there's a formula to apply.

The concept of 'relatively prime' is new to me (meaning not sharing all the same primes?). Still I am fascinated by this walking one gear around the other as it is new to me. I was aware of planets do this, but hadn't consider it a means to make gears fit better via even wear.

There are 2 fixed shaft center dims. 2.125". So to use 2:1 from one shaft to the other, the outside diam is approx 3" on the larger gear, which is too large. I need the larger gear <= 2". This makes me think to add a third gear to achieve the goal.

-Phil