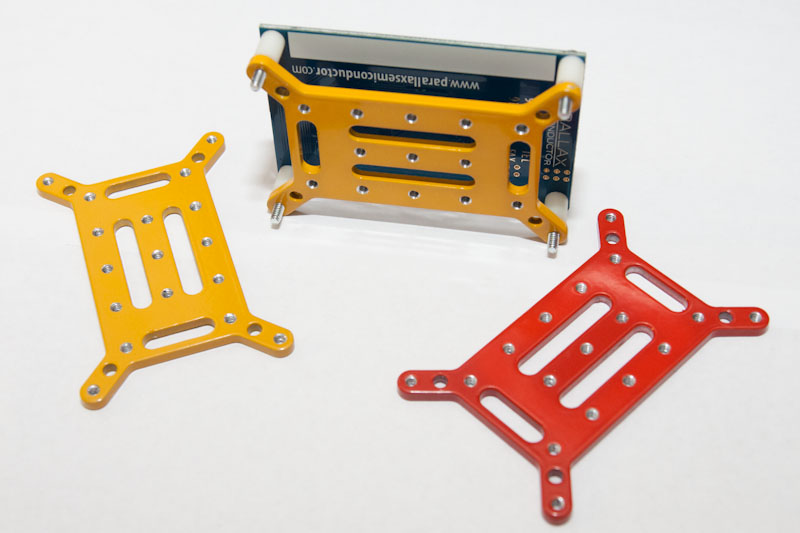

Quickstart mounting adapters/brackets.

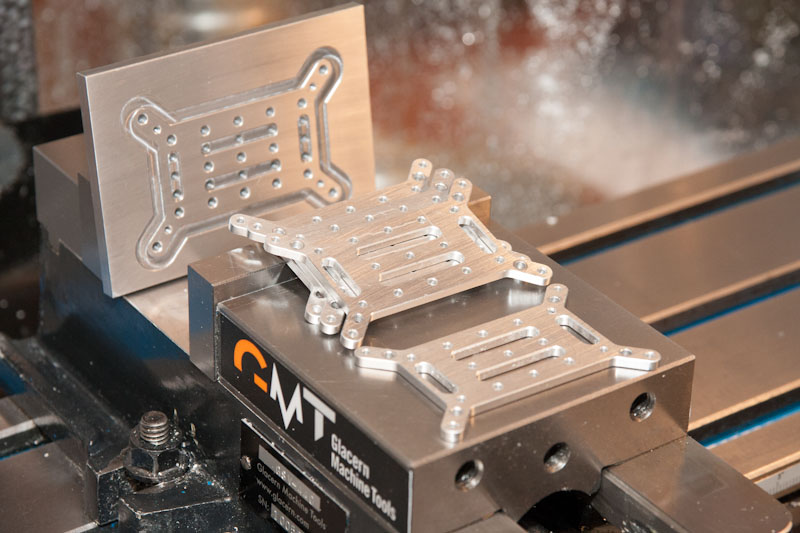

In the process of building out my robot I designed it with a 0.500" grid of mounting holes for locating parts, sensors and electronics. Problem is that often the spacing on electronics is usually just whatever happens to fit. In this case the Quickstart is 2.75 by 1.75 and while there is nothing wrong with that it certainly doesn't work with my adaptable grid design and the Arduino is worse. All I could do was attach a single stand-off on both boards. So I made a few adapters that I hoped would also be useful in other projects as well. They would adapt to both a 1" and 0.5" grid and have slots to allow for non-square/non precise mounting.

The holes were all tapped as 4-40 except for the ones used to hold it for machining. The slots are 0.195" and would accomodate #4 or #6 screws with washers or #8 screws as well. One set of slots would mount on 1" centers, while the other would mount on 0.500" centers. They were all powder-coated here at home.

I really like how they came out. Worked nicely for getting the boards secured to the robot in a nice solid manor and can be moved from place to place with ease. I have 2 left from the test run I made and if anyone is interested in them you can send me an email at kyle@cranehome.info if you'd like to have one. I'll give these two away for the cost of shipping. If there is any other interest in them I imagine I could make up a small run or two. Colors can be matte black, gloss yellow, or gloss red.

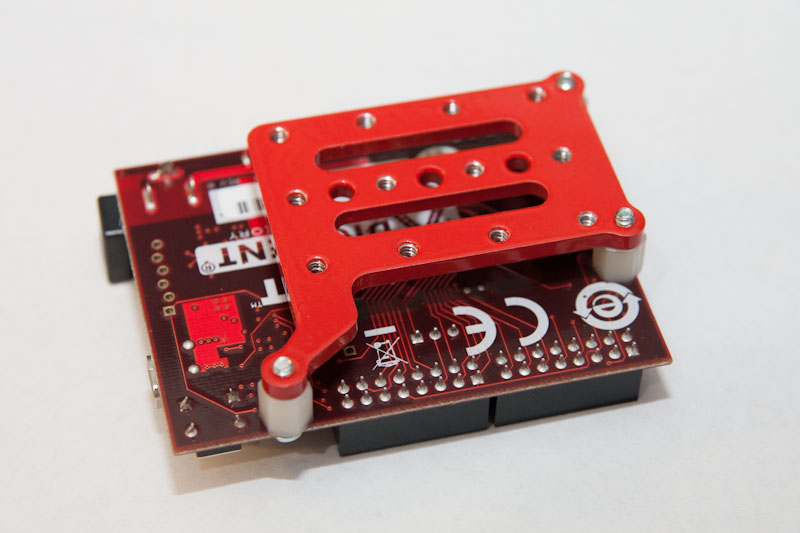

Also pictured is the Arduino Uno version. Both are made from 0.125" AL and weigh in at 0.5oz.

The holes were all tapped as 4-40 except for the ones used to hold it for machining. The slots are 0.195" and would accomodate #4 or #6 screws with washers or #8 screws as well. One set of slots would mount on 1" centers, while the other would mount on 0.500" centers. They were all powder-coated here at home.

I really like how they came out. Worked nicely for getting the boards secured to the robot in a nice solid manor and can be moved from place to place with ease. I have 2 left from the test run I made and if anyone is interested in them you can send me an email at kyle@cranehome.info if you'd like to have one. I'll give these two away for the cost of shipping. If there is any other interest in them I imagine I could make up a small run or two. Colors can be matte black, gloss yellow, or gloss red.

Also pictured is the Arduino Uno version. Both are made from 0.125" AL and weigh in at 0.5oz.

Comments

I just sent you an email.

-Phil