Diagonal cutter showdown: Taiwan (?) vs. Japan (?) tools

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

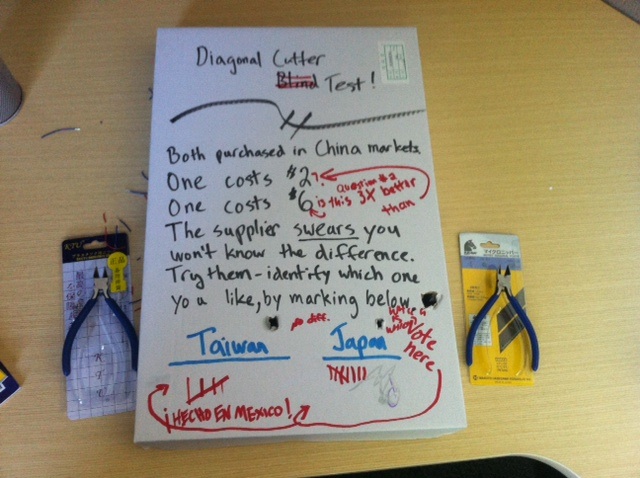

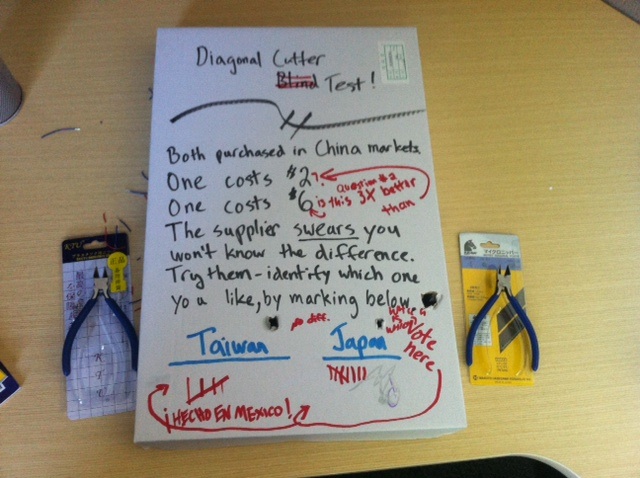

Parallax doesn't resell a lot of items, but those we do we carefully evaluate to make sure they're the best we can procure. On a trip this month to China we spent a couple of days wandering the component market. But we want the "best" we can get, right? Maybe the best for the dollar (or RMB, as in this case). We need some diagonal cutters for our kits, so we sampled two brands, one from Taiwan and the other from Japan. Although, let's face it - these are from China and do I really believe they imported tools from Taiwan and Japan? Not really. They can copy nearly everything, very nicely.

So perhaps these are really Chinese tools, but branded as Taiwanese and Japanese. Who knows. You really can't find out.

Anyway, the Taiwanese ones cost us about $5-6 (maybe about $4 after serious negotiation and purchasing several hundred units) and the Japanese ones cost about $2. We would have thought the Taiwanese versions would have been of better quality. I really couldn't tell much of a difference, so I invited the manufacturing staff in for a blind test. These people know what they're looking at - they buy Lindstrom cutters at $70 a piece and use them like surgeons all day long across two shifts. Manufacturing staff who voted did so with strong conviction and preferred the Japanese version which is much less expensive.

Other people in the office who don't normally use these tools also cast a vote, but with a bit less enthusiasm.

So, the less expensive cutters were deemed of much higher quality. They're nicely machined and cut perfectly.

I know I have other far more important things to do, but I really enjoy the simple tasks at Parallax.

Ken Gracey

So perhaps these are really Chinese tools, but branded as Taiwanese and Japanese. Who knows. You really can't find out.

Anyway, the Taiwanese ones cost us about $5-6 (maybe about $4 after serious negotiation and purchasing several hundred units) and the Japanese ones cost about $2. We would have thought the Taiwanese versions would have been of better quality. I really couldn't tell much of a difference, so I invited the manufacturing staff in for a blind test. These people know what they're looking at - they buy Lindstrom cutters at $70 a piece and use them like surgeons all day long across two shifts. Manufacturing staff who voted did so with strong conviction and preferred the Japanese version which is much less expensive.

Other people in the office who don't normally use these tools also cast a vote, but with a bit less enthusiasm.

So, the less expensive cutters were deemed of much higher quality. They're nicely machined and cut perfectly.

I know I have other far more important things to do, but I really enjoy the simple tasks at Parallax.

Ken Gracey

Comments

You might want to test & check that the rubbery (I assume it is) holders would not loose its grip to the steel handler after some serious & long cutting ...

Thanks for the tip - I didn't think about that.

Ken Gracey

-Phil

Expensive cutters! http://www.amazon.com/s?ie=UTF8&field-keywords=SWANSTROM%20TOOLS%20USA&index=tools&search-type=ss

The Lindstrom cutters are spendy too: http://www.amazon.com/s/ref=nb_sb_noss_2?url=search-alias%3Daps&field-keywords=Lindstrom+cutter

The Plato cutters are much more reasonable: http://www.amazon.com/s/ref=nb_sb_noss?url=search-alias%3Daps&field-keywords=plato+model+170

As many of you know, my wire bending CNC machine bends and cuts music wire, but when adjusting the straightening rolls on the wire straighteners, it is often much easier to cut the test lengths with diagonal cutters. After literally hundreds of cuts of 0.032" music wire, my Klien 6" Heavy Duty High Leverage Diagonal Cutters show very little signs of wear, except where I shorted them on a live 120V circuit (ooopppsss). These diagonals are very durable and will cut 10-32s with a little effort.

That is all I have to say about the issue

Bruce

EDIT:

Okay, I lied...

The moral of this story is:

The Japanese make a lot of very nice high-quality tools due to learning from the Germans before WWII, but these days there are a few Japanese manufacturers that occasionally slip in poor quality while asking for higher price.

Also, you might want to evaluate needle nose pliers. The cheap ones have their tips bend when you tightly grip a coin, such as a penny or a nickle. The good ones are tempered and won't bend.

Good tips. Thanks!

Well there you have it in nutshell!

Hardened steel cutters are much more durable than non-hardened cutters, not necessarily better quality, but the cutting edge will last a lot longer. Generally hardened steel will have a grey to charcoal tint to the metal, indicating that it has a higher carbon content. If you wanted to be thorugh, you could always perform a brinell hardness test to verify the hardness of the metal

Do you include safety goggles ?

Another test for cutters, is the 'ping speed' - how fast does that snipped end, fly across the room ?!

I've seen some cutters that attempt to hold the snipped lead and the ones here certainly vary in that detail.

[video=youtube_share;e7iwQKi38Rk]

I have a couple Xcelite cutters and also some of the low cost ones. If you have extra pairs of cutters I would set aside one of each brand for testing how they hold up to a lot of use and some abuse.

The quality of the cheap cutters vary a lot. Some of the cheap cutters are excellent, others seem ok when new but don't last long. The two issues that came up on which made them unusable were:

- The blades weren't hardened and either quickly dulled or may deform after cutting may leads or tougher material. (The better ones last much longer)

- The pivot point wears out quickly on some of the cheap ones and with the extra slop the blades no longer close flush or may close flush but be off from side to side making it useless as a cutter.

I have 3 or 4 pairs of these scattered around. I love the flush cut. I was initially surprised that I like them so well, given their inexpensive price. They excel at trimming the excess off your ti-wraps; they don't leave that little plastic 'point' sticking up like regular diagonal cutters.

I use pros kit as of now as I can get them at cost . last about a year ...

Peter..

I, in another life at Unisys, used them and never wore one out until some BONE HEAD cut steel wire or some such.

I seem to remember they were Diamalloy 25 years ago.

Duane J

The cutting edges are easily damaged if you misuse them. I like them because they are the flushest cutters I've found, light, padded, and spring return. The are stamped "Made in USA" on metal. They are hardened and deflect, but don't bend.

I misuse and abuse tools in all sorts of ways. I obviously wouldn't be able to use these cutters as a sledgehammer.

Bruce

-Phil

Only if necessary

Since we are on the subject of knives now, I will tell you that the Buck Model #119 makes a better hunting knife than a throwing knife. Back in my youth, every once in a while, I would practice throwing the 119 at a big cottonwood tree from about 15 -20 feet away, and I must say that I was getting real good at getting it to stick pretty deeply. Imagine my dismay when the knife improperly struck the tree and snapped in half.

Bruce