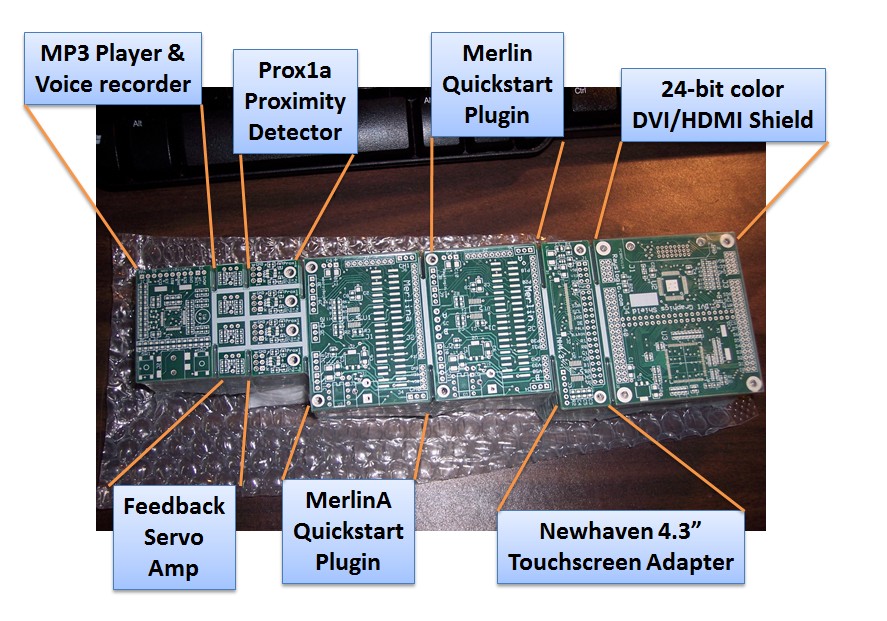

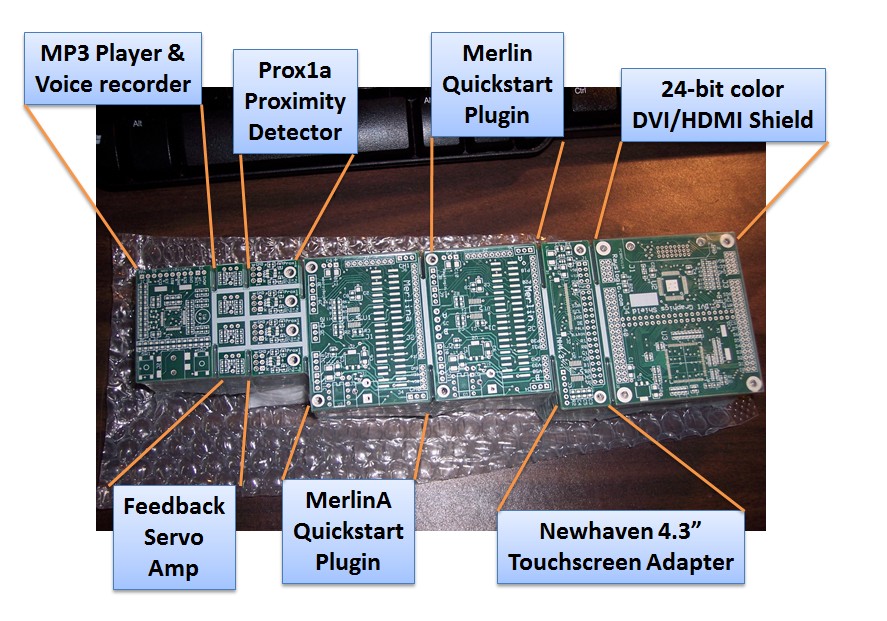

Multi-Prop Toy PCBs

Just wanted to share my latest scheme to get production boards from ExpressPCB at a reasonable price...

The setup fee for production is a real killer at $250... In an attempt to reduce costs, I've combined a bunch of projects onto one board...

They wouldn't let me connect them by real thin sections, so they are substantially connected.

This means I'll have to break out the saw to cut them apart.

Right now, this seems like a very clever idea. But, I haven't cut any apart yet. I might change my mind after that...

Anyway, take a look (I hope at least a couple of these boards actually work):

The setup fee for production is a real killer at $250... In an attempt to reduce costs, I've combined a bunch of projects onto one board...

They wouldn't let me connect them by real thin sections, so they are substantially connected.

This means I'll have to break out the saw to cut them apart.

Right now, this seems like a very clever idea. But, I haven't cut any apart yet. I might change my mind after that...

Anyway, take a look (I hope at least a couple of these boards actually work):

Comments

Looks like a good time for the very sharp razor knife + metal straightedge + scribe heavily top and bottom + snap off method. Works best if you sandwich the part you're snapping from between two blocks of wood, and use a third block to evenly torque down on the one you're snapping off.

A nibbling tool is the most precise way to do this, but very tedious and you have to leave a wide enough gap between boards for the head.

Don't even think of using a hacksaw or scroll saw. I've used a hacksaw on breadboards where there were rows of predrilled holes to guide the way, but I'd never consider a toothed saw for this kind of separation.

Of course you could always stick it in your CNC laser cutter ... you do have a CNC laser cutter, don't you? I don't use mine very often but I keep it in the pantry behind the Doritos in case of an emergency.

Right now, I use a wet saw (ceramic tile cutter). It actually cuts PCB like butter. It is "wet" though and requires clean up...

The white lines on the board are exactly the width of the blade (fairly thick).

The slots in the PCB are just a hair bigger than this.

Cut up 10 of these boards last night, wasn't too bad.

Very impressive! Could you provide some more details on how you do that? For example, what exact type of saw are you using? Is this a powered device or something you do by hand?

Thanks.

It's just a plastic frame with a diamond blade and a motor... Not much to it. Don't remember exactly how much it costs, but definitely <$100

Interesting. I would get one but I'm afraid I would need to hide the box and put a sticker on it that says PCB Cutter. Otherwise my wife would start nagging me about the bathroom floor.

I usually end up scoring and snapping boards apart. Some boards will eat regular saw blades. An Xacto razor saw works ok, but can take forever. I have used a regular scroll saw before but after a few inches of cutting, the teeth were completely gone from the blade.