SpindleBots - Construction artilce in April 2012 SERVO magazine

RobotWorkshop

Posts: 2,307

RobotWorkshop

Posts: 2,307

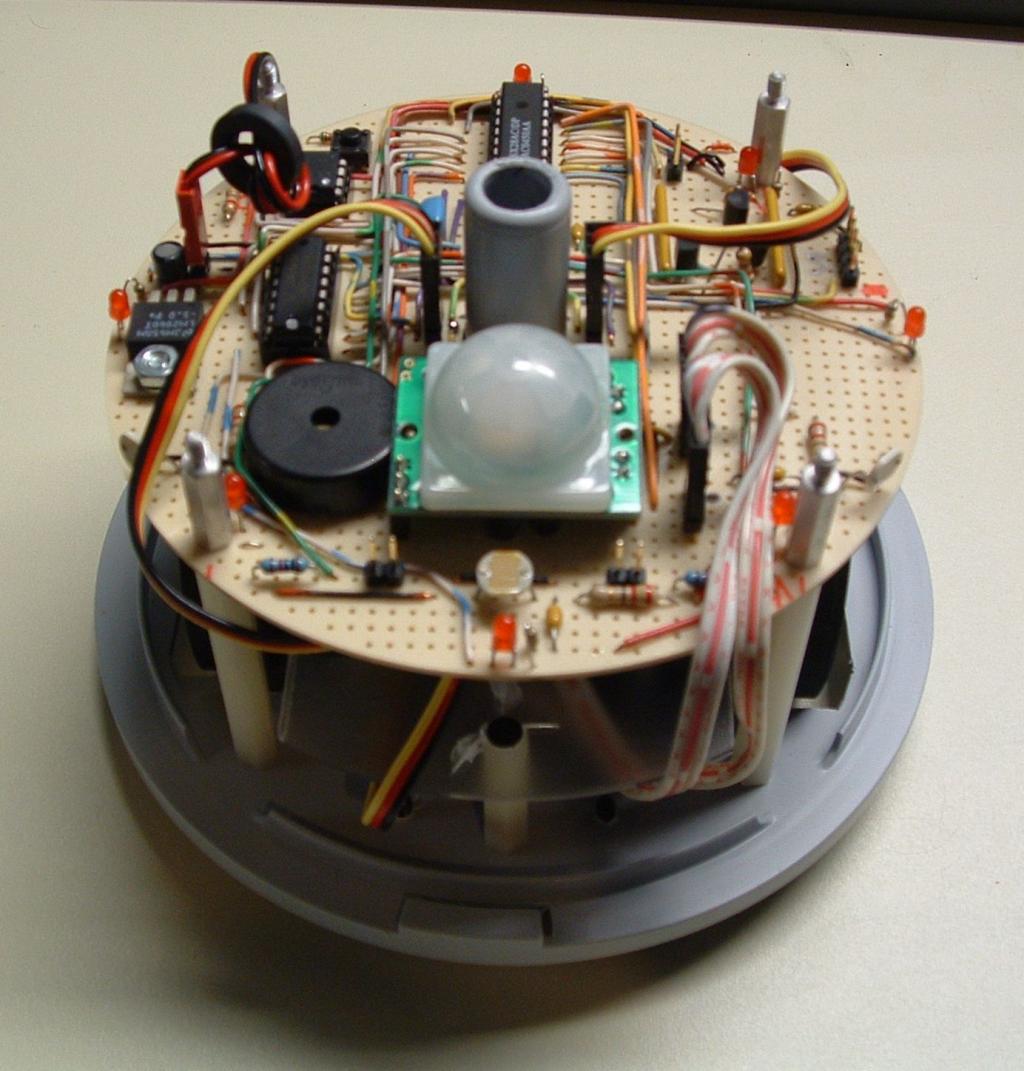

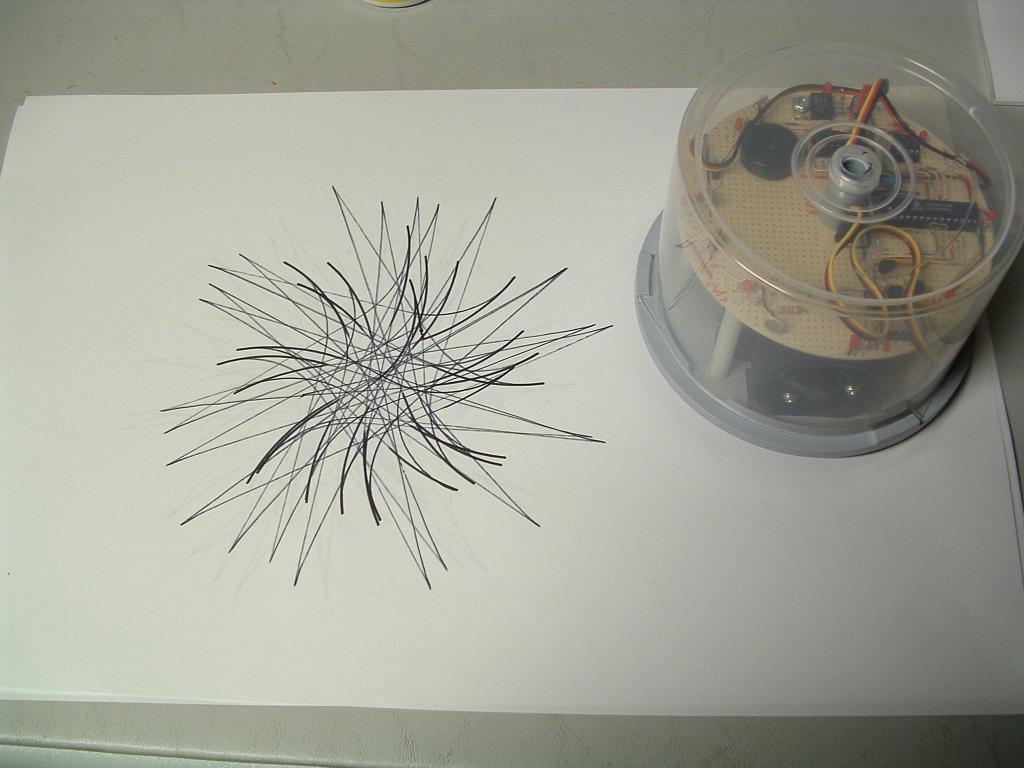

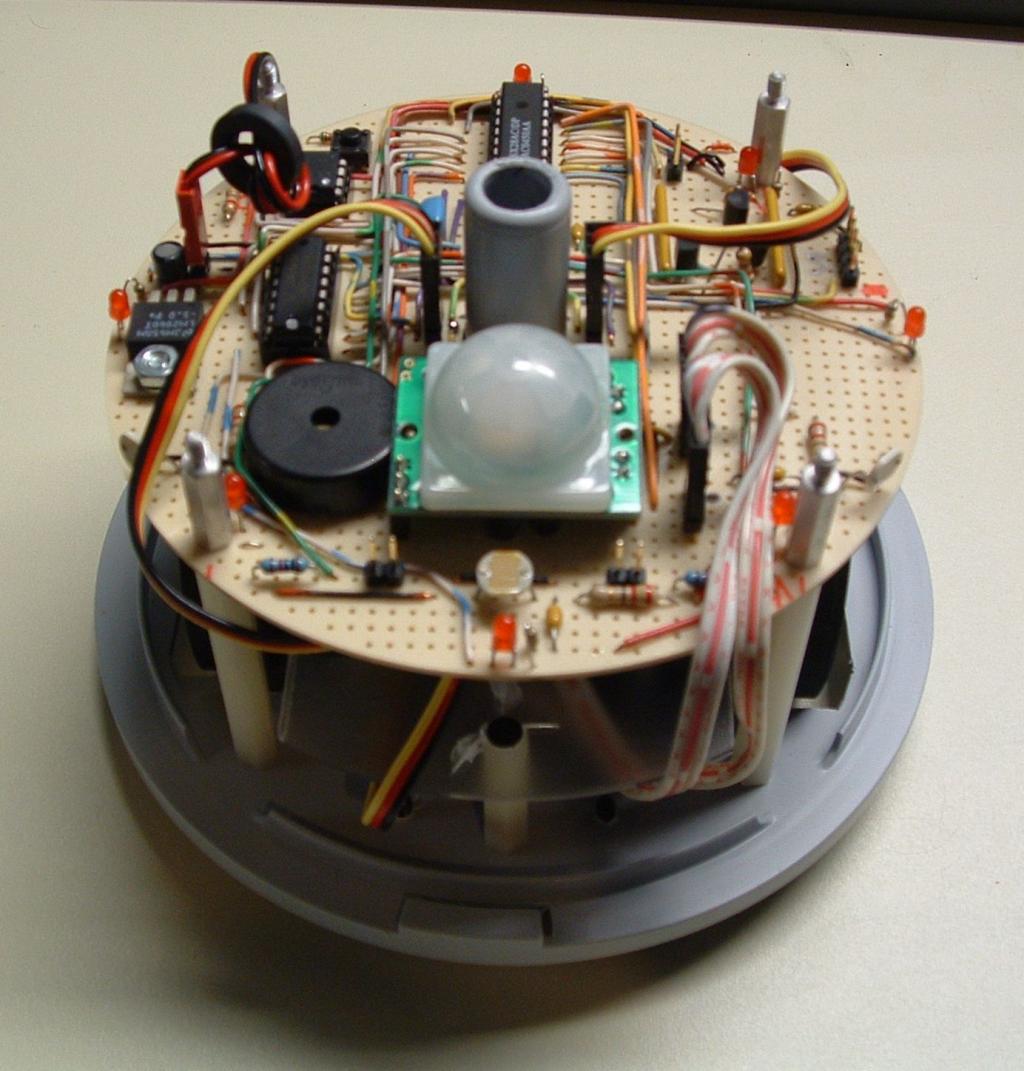

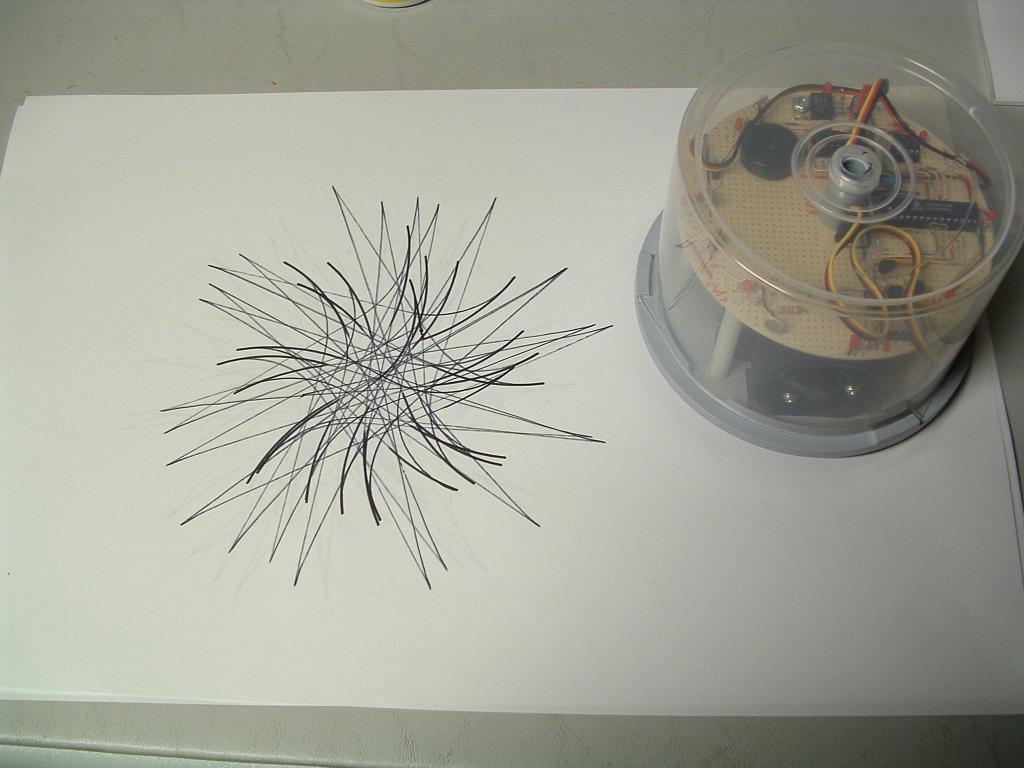

I designed these SpindleBot robots many, many years ago and finally had an opportunity to write them up! The article is due out in the upcoming April 2012 issue of SERVO magazine. It is more about the construction of the robot and how to build one instead of focusing on a particular processor. Just about any one of your favorite chips can be used. Think of it as a Boe-Bot or Scribbler in a CD case. They all use a CD/DVD Spindle as a base and use the cover to keep a nice finished look on the completed robot. The first one used the original BASIC Stamp 1, the followup version and OEM BS2SX on a special CDP2 CD PCB prototype board, and the last version uses several prototype boards stacked up and has run both a BS2p40 and one of my prototype 40-pin DIP Propeller modules. Just about any CD/DVD Spindle can be used.

To help classify the robots I used the old floppy drive scheme. 100 CD Spindle (Full Height), 50 CD Spindle (Half Height), and 25 CD Spindle (Quarter Height). The article will have a handy template that will make it easier to cut out the base and mark the location for the mounting holes. These robots also use some other recycled components like the wheels and the article covers some other parts that can be used as well. The latest build of the SpindleBot packs quite a bit in a small space and it much more refined than the first robot.

Everyone that has seen these in person really likes them and I thought it was long overdue to start writing about these and get some pictures posted.

If you read the article and have any questions about the construction let me know and I'll do my best to answer them.

Best Regards,

Robert

To help classify the robots I used the old floppy drive scheme. 100 CD Spindle (Full Height), 50 CD Spindle (Half Height), and 25 CD Spindle (Quarter Height). The article will have a handy template that will make it easier to cut out the base and mark the location for the mounting holes. These robots also use some other recycled components like the wheels and the article covers some other parts that can be used as well. The latest build of the SpindleBot packs quite a bit in a small space and it much more refined than the first robot.

Everyone that has seen these in person really likes them and I thought it was long overdue to start writing about these and get some pictures posted.

If you read the article and have any questions about the construction let me know and I'll do my best to answer them.

Best Regards,

Robert

Comments

These look like fun kid-oriented projects (even for us older kids!). I like the junk-drawer, reused parts projects.

Thanks for sharing!

Ugh! I already have too many projects, now I have to make one of these.

I think mine will need at least one ring of LEDs.

I look forward to reading the article.

Can a Spindlebot do a figure 8?

Zip ties rule!, what is that you have strapped down? looks like the motor mounts.

oh, and +1 on the figure 8...

-Tommy

I bet three zip ties the zip ties are holding CR servos in place. If you look at the wheels, you can see the white servo horns.

I also +1 on the figure 8. How many +1s does it take to get someone to do a figure 8? Eight?

Robert

If you end up building one of these SpindleBot robots I have the Prototype PCB's on hand to make these so you can take advantage of the form factor. I had also used one of these CD PCB boards to create a hand wired Hydra in a CD case.

Robert

http://www.servomagazine.com/index.php/magazine/issue/2012/04

It should be clear from all the pictures in the article just how these are assembled but I'll be glad to answer any questions that come up.

If you build your own version I'd like to hear how it turns out.

Robert

(and way to go Gordon (again) and Parallax for some ELEV-8 press)