Please check my Gear Math.

Im building a robot arm and for the elbow joint I have designed this around the Dynamixel RX-64

Spec's say it makes 888 oz-in holding torque at 18v.

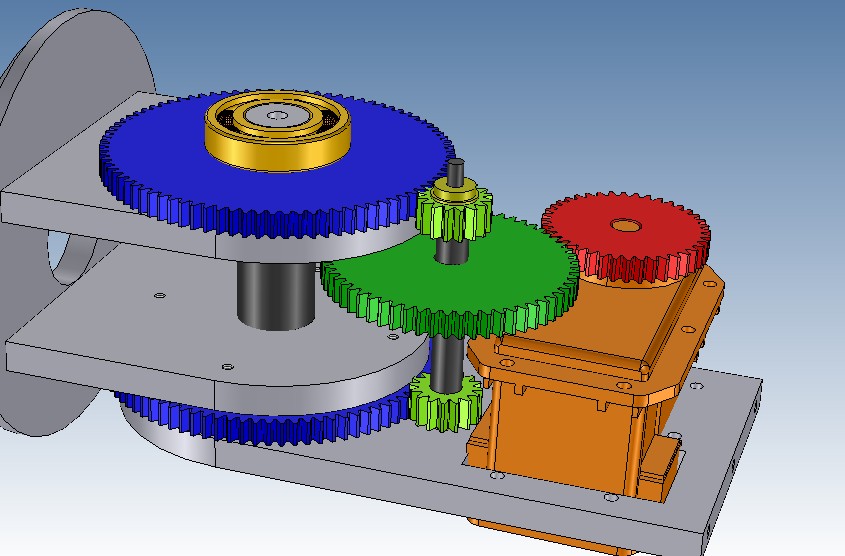

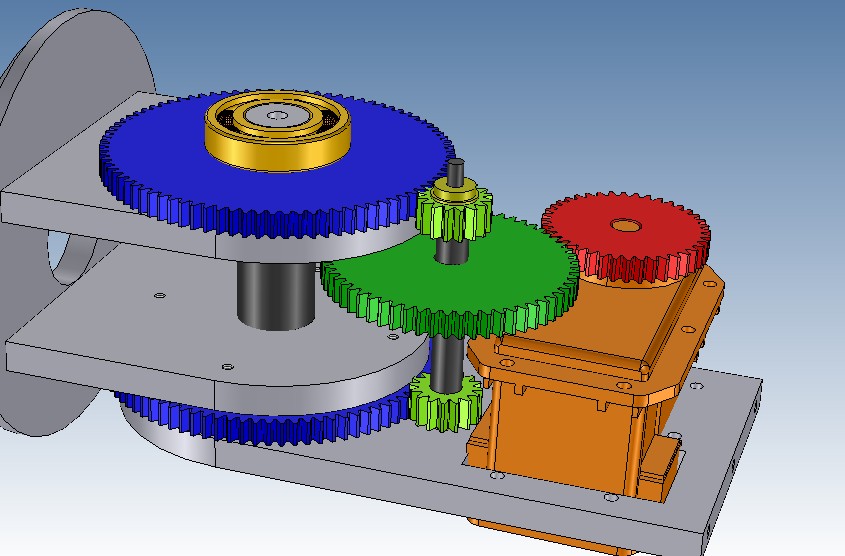

So the red gear on the Dynamixel is a 40 tooth connected to that is the large green gear which is 60 tooth. = 1.5 speed reduction and 1.5 x torque increase.?

The large green gear and the small 16 tooth gear connects to the large Blue 86 tooth gear. 5.375 speed reduction an 5.375 x torque increase?

so:

888 x 1.5 x 5.375 == 7159.5 oz-in or 37.28 ft-lbs

Is this correct?

thanks

Spec's say it makes 888 oz-in holding torque at 18v.

So the red gear on the Dynamixel is a 40 tooth connected to that is the large green gear which is 60 tooth. = 1.5 speed reduction and 1.5 x torque increase.?

The large green gear and the small 16 tooth gear connects to the large Blue 86 tooth gear. 5.375 speed reduction an 5.375 x torque increase?

so:

888 x 1.5 x 5.375 == 7159.5 oz-in or 37.28 ft-lbs

Is this correct?

thanks

Comments

The max torque won't be perfectly that because of efficiency and other considerations (how rigid you can make the system, how much the teeth flex).

The 16 tooth gear is going to have a sizable amount of stress put on it (because of the minimal amount of material).

Just make sure the gears themselves are up to the challenge. But this arrangement is done all day, every day.

Also consider shock load (defined by whatever your application is), which could be many, many times the torque you're seeking to achieve.

I smell stripped gears and broken housings... not to mention broken hearts and shattered dreams!

The above assumes you'd have a torque requirement even a 10th of that. While I wouldn't directly drive off the Dynamixel's output shaft, the motor alone has a holding torque of over 4.5 ft-lb. That's quite substantial right there.

-- Gordon

??? You can have torque without rotation, thus zero horsepower.

Technically, 1 HP would be 550 ft-lb per second, but I'm relating more to equivalent torque (think beefy AC motor or a gas operatated snowblower), and the type of mechanics needed to support that kind of load.

-- Gordon

There is a second plate to capture the gears.

All the plates are 6061 .250. The 2 large bearing are plastic but I changing that because I messed up the first set of machined plates and I dont like the look of the assemblly.

I designed the elbow to fit inside of the Bicept and forearm tubes which are carbon fiber 3.5 and 3 inch.

So this elbow joint will have to support the forearm rotate and the wrist joint and Hand which I'm thinking will be made from Rx-28's

The small 16 tooth is .5 (steel)

the 60 tooth is 1.875 (Acetal)

and the 40 tooth is 1.25 (Acetal)

I have the option of aluminum gears but the plastic are lighter and cheaper for now.

Dave How did you calculate the force on the teeth?