Propeller Board of Educations being assembled on the Pick-n-Place

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Caught the first part of a 500-unit Propeller BOE production run this afternoon. Didn't get to photograph all of the steps, but here's a snapshot. The crew is working two shifts to get these boards finished.

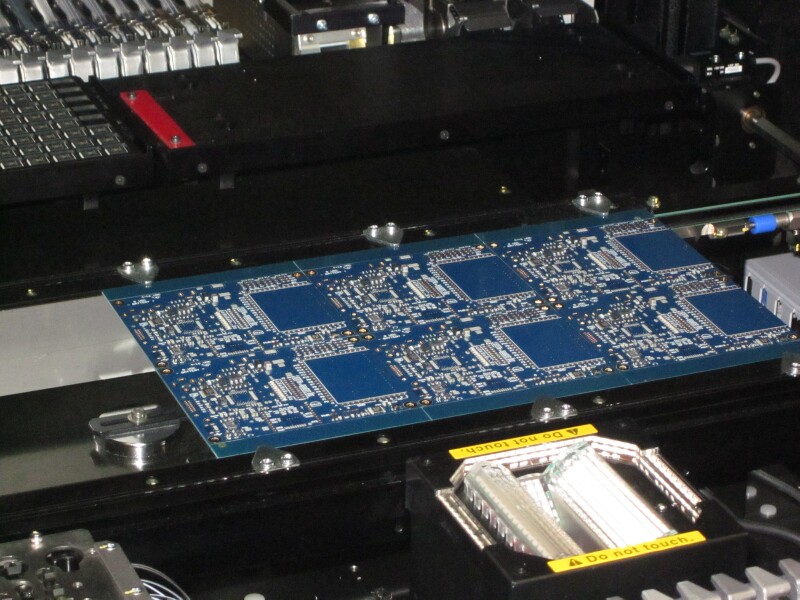

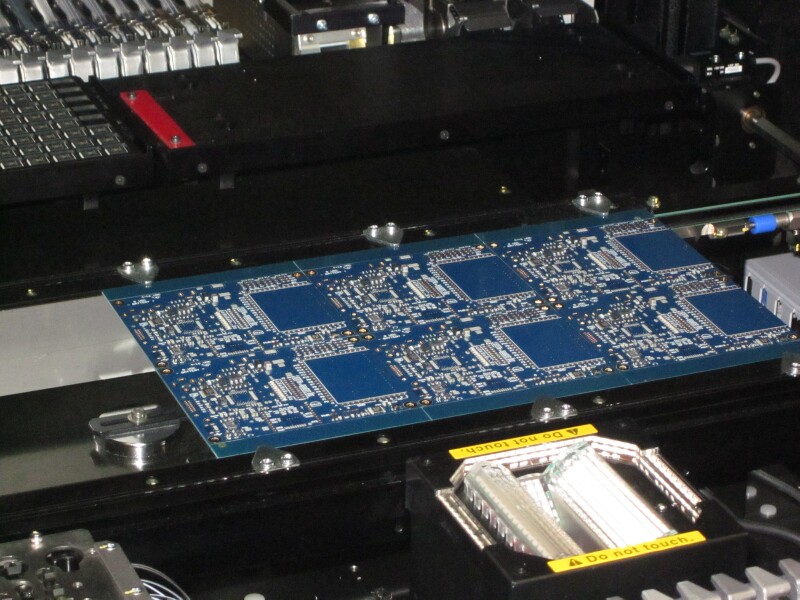

1. Boards are panelized 6-up. First step is on the screenprinter where solder paste is applied to the pads.

2. Next stop is the Pick-and-Place. Note that feeders are loaded on both sides of the machine - lots of parts on this board.

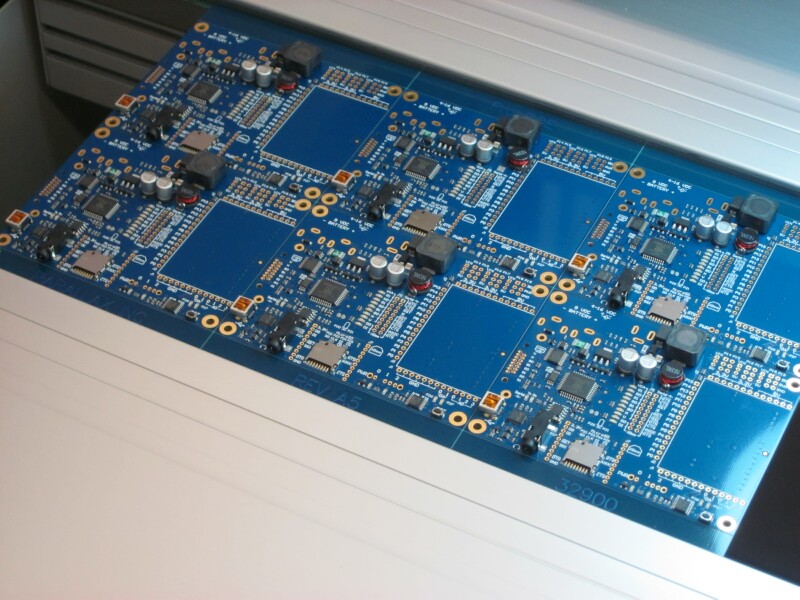

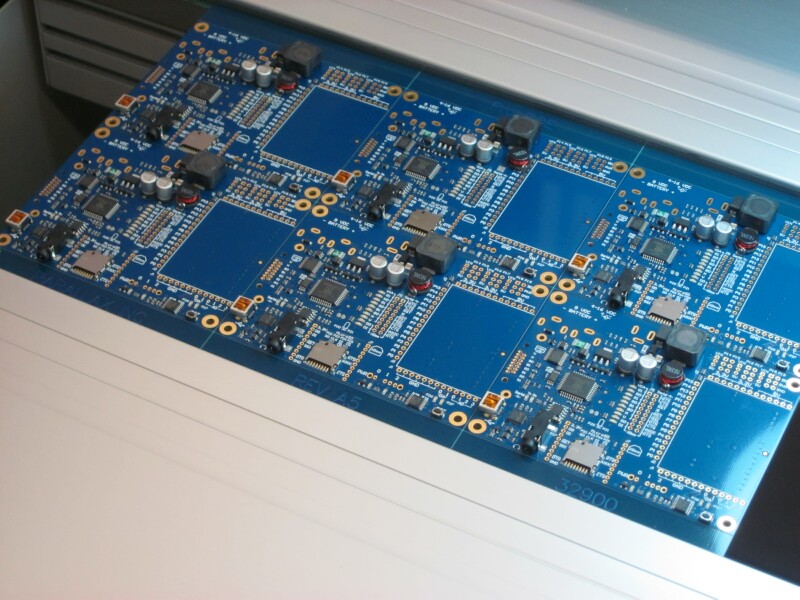

3. Visual inspection before the reflow oven.

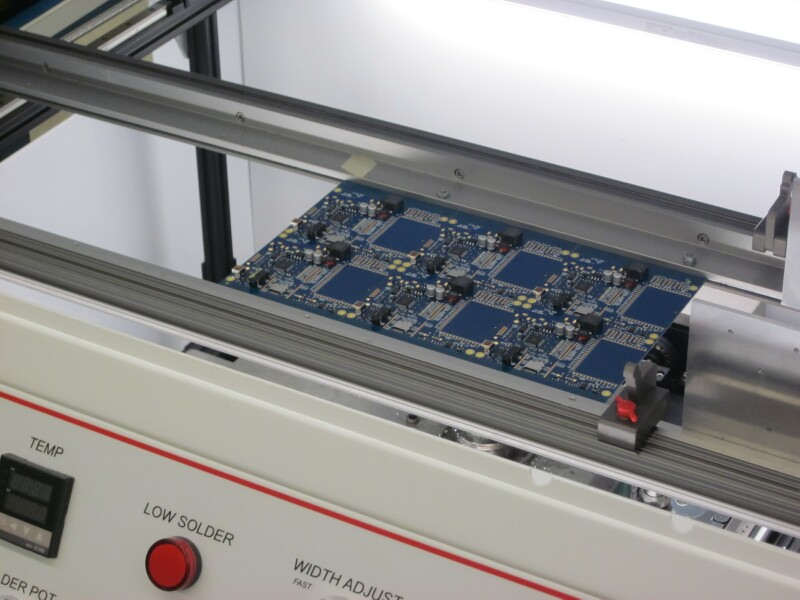

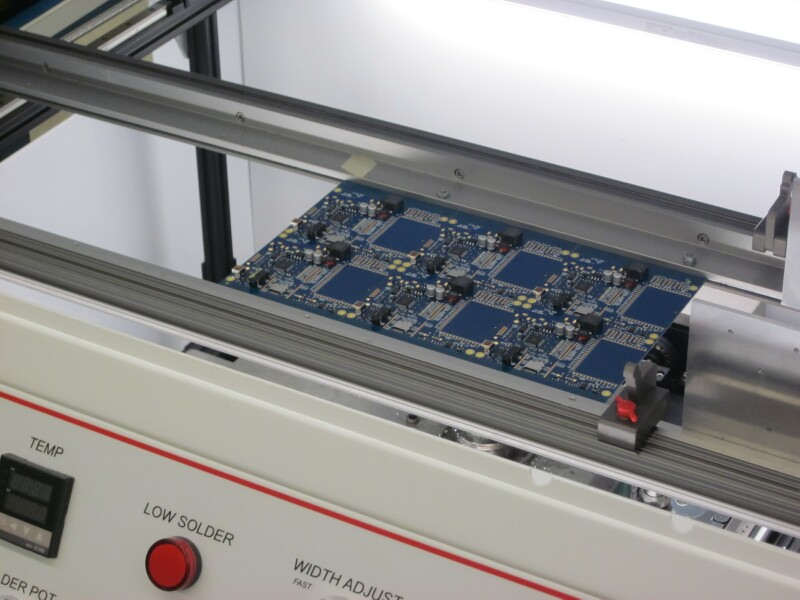

4. Boards eject from reflow oven.

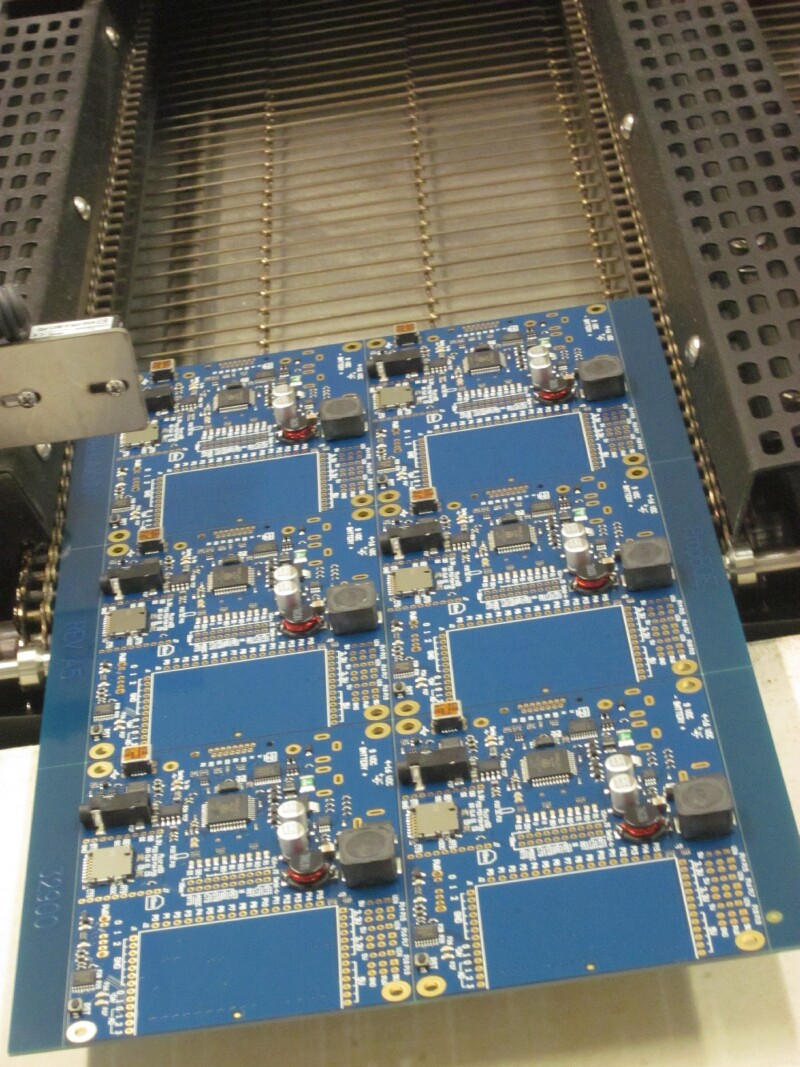

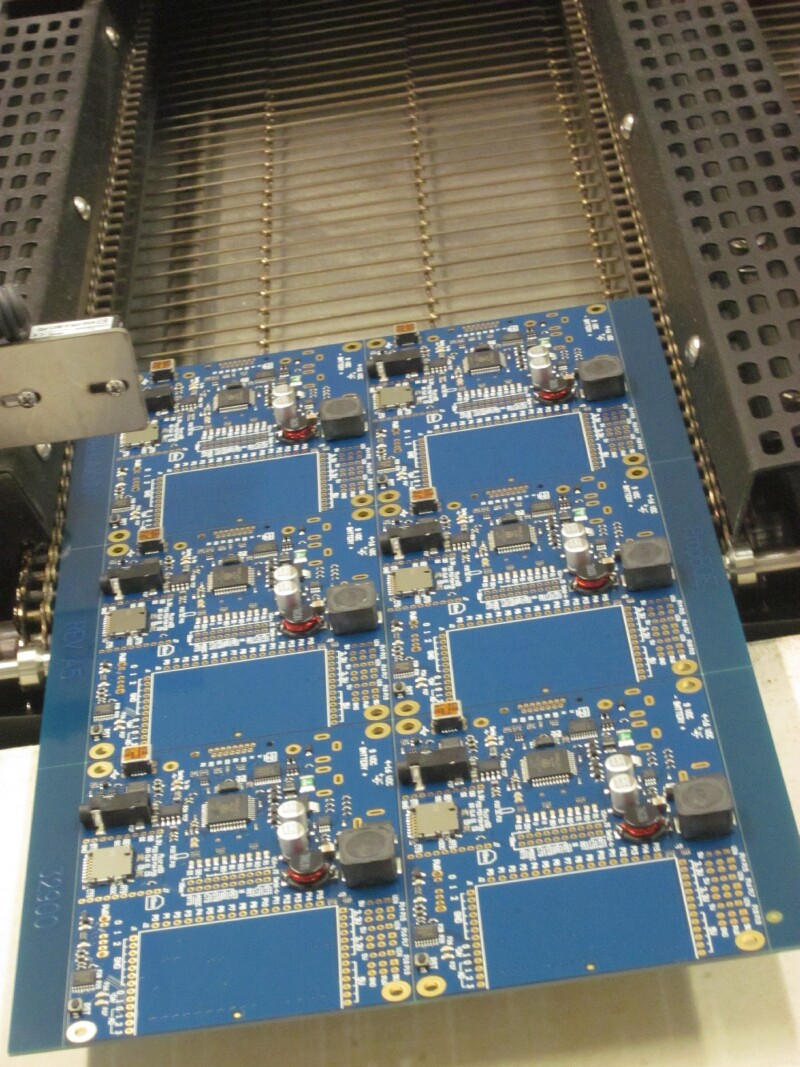

5. Stuffed with through-hole parts and loaded into the selective solder. Special fixtures hold the panels to keep them flat.

5. Sent through pizza cutter to separate into singles.

6. Breadboard attached.

7. Test, packaging, shipping.

1. Boards are panelized 6-up. First step is on the screenprinter where solder paste is applied to the pads.

2. Next stop is the Pick-and-Place. Note that feeders are loaded on both sides of the machine - lots of parts on this board.

3. Visual inspection before the reflow oven.

4. Boards eject from reflow oven.

5. Stuffed with through-hole parts and loaded into the selective solder. Special fixtures hold the panels to keep them flat.

5. Sent through pizza cutter to separate into singles.

6. Breadboard attached.

7. Test, packaging, shipping.

Comments

@mindrobots - Maybe so! We'll repeat this process for about 100 more times to make over 500 units in the next couple of days. We'll probably finish all of these before we ship a single unit. I really need a couple of these too since I'm working with various prototypes that seem to be missing key components. Since you're a writer and I'm a business person I'll make sure you get one before me. Same for Tymkrs, too.

We're carefully spending your money to give you the finest quality product with a lifetime guarantee, made in the USA. If anybody's thinking about buying one of these you should know that you have no risk whatsoever - we want our customers to be happy with this board and the educational program.

Ken Gracey

Roy

We have about 75 pages of content developed on a prototype PropBOE that need to be updated with the actual production units so we can continue releasing a ton of material. We already released some here:

http://learn.parallax.com/PropellerBOE

But after we have the boards we will be back on track updating more content as explained here:

http://learn.parallax.com/node/168

Ken & Aristides, with a lifetime guarantee, made in the USA and awesome educational material I can't see why any educational program wouldn't invest in these boards from Parallax.

Glad to be a Parallax customer,

Tony

In the video of the pick-&-place activity, there's a moment when the "head" passes over a part of the machine and a "flash" occurs.

What's that about?

That's the camera and a flash, providing part positioning prior to placing on the board.

Ken Gracey

Same here - I just ordered one.

Didn't get an order confirmation Email though ??? - maybe because it is a pre-order...

I couldn't find a board schematic anyplace - is it available?

Here ya go Ron, post #68

http://forums.parallax.com/showthread.php?137235-Propeller-Board-of-Education-Quick-Look-and-Pre-order/page4&highlight=Propeller+BOE

@hover1,

Thanks! That post says "preliminary" but certainly helps!

...okey dokey - thanks!

To answer your question, Parallax owns the building so relocation is a bit complex (sell this, buy another one). If we grow the Propeller business to higher levels of success then we'll look carefully at a 40-50K SF building in the next couple of years. I can certainly see this being part of our plan in the next five years. We need double the space in manufacturing, double the warehouse, and probably about 20% increase in office area. Hopefully we will grow before the recession is over so we can take advantage of the many vacant buildings in our Tech Center. Several large office/light manufacturing spaces were in progress around 2006 and never occupied, and are now owned by banks.

Ken Gracey

When I was up at Parallax last May it didn't seem over-crowded, so whatever the space it must be pretty efficiently used. Even MattG's office, with that big beam-thingie machine, looked like a pretty nice playground area.

-- Gordon

It's not just Louisiana. The whole South is putting on its friendly to business face. You should do some looking around down here. California is being kind of crazy lately. We aren't taking apart our public infrastructure to pay obeisance to some weird political philosophy. We have state parks and libraries that aren't scheduled to close soon.

Oh, and our 20,000 sqft place in the suburbs of Memphis is mostly empty. Long story there. Might be an opportunity. It's small manufacturing form factor, and the people who own it aren't quite sure why there's a wall with no doors separating the backmost bay from the rest of the building. I've told them that's the dirty area, but haven't ever actually operated an operation where that distinction is important.

Parallax could slash their housing costs by moving to City of Industry, or even Vernon (both are near LA, heavily industrialized, and cheap -- they're favorites of the Chinese importers because there are no business licenses or business tax levied), but why would would they want to? There's more than just cost per square foot.

I can get a pretty decent office space/warehouse in C-of-I -- remember zip taxes -- for 50 cents a square foot. Half a mile from the freeway. About 20 miles to LA, an hour's commute if you don't go at the right time of day. See what I mean?!

-- Gordon

Short answer: either this Friday the 16th or Monday the 19th. If everything goes according to the [new] plan, even Thursday is a possibility.

Here's what happened, for those who are interested. Parallax is a system-driven place - all of the materials and supplies are automatically procured according to an ERP-MRP system with about 50 parameters per part number. All of the fantastic calculations done by the system don't seem to work if we feed it garbage, or don't feed it at all. Somehow the engineer left the little breadboard off of the Bill of Materials and even a double-checked system failed. Early last week we realized we were totally out of these breadboards and that those we had were securely mounted on other boards. An action plan was quickly put in place and we have a few thousand breadboards shipping from Taipei this morning (our Sunday evening is their Monday morning). Our Purchasing Manager and myself are both in constant communication with the supplier, who's going out of their way to solve our problem.

The Propeller BOE boards are built and tested. The production process went very smoothly. They just need breadboards.

Ken Gracey

Well at least is was minor problem and not a design or production issue!

Is a final schematic going to be available, I believe some changes were made.

Thanks,

Ron

@Ron, thankfully! Jessica really kept the troops coordinated on this project. You can thank her, Andy and David for the fact that we sent a complete product to manufacturing. This product had many prior revisions, both by hand and on the SMT manufacturing line. This experience really reduced the potential for production problems, though errors still do occur from time to time which might not be easy to anticipate. For example, new feeders on the P&P machine might pose some handling issues or some components may not take the reflow heat as well as others.

Ken Gracey

The final schematic will be posted at http://www.parallax.com/tabid/514/ProductID/805/Default.aspx when we ship the PropBOEs. There won't be any technical differences from the schematic at http://forums.parallax.com/showthread.php?137235#post1073589.

— David Carrier

Parallax Inc.

Goody, last I note 18 March was the approx. shipping date. Is that still accurate?

Fascinating to see the board assembly. Pick and place sure is faster than a human could ever do it for a few seconds.

Things shown so fast "I didn't see mine being assembled", but that is OK with me. Gonna be a long week waiting. Thanks for the photos and video.