Phil's veho360 Speaker Mount on a Propeller BOE Robot

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Hey there,

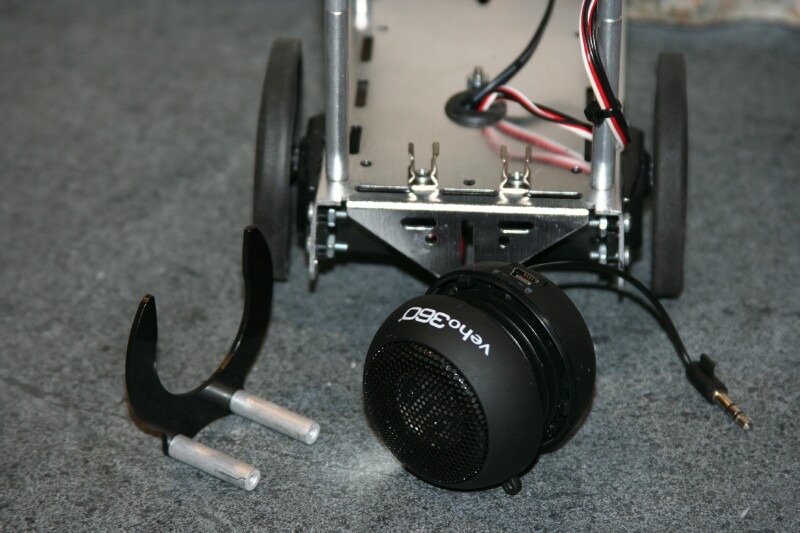

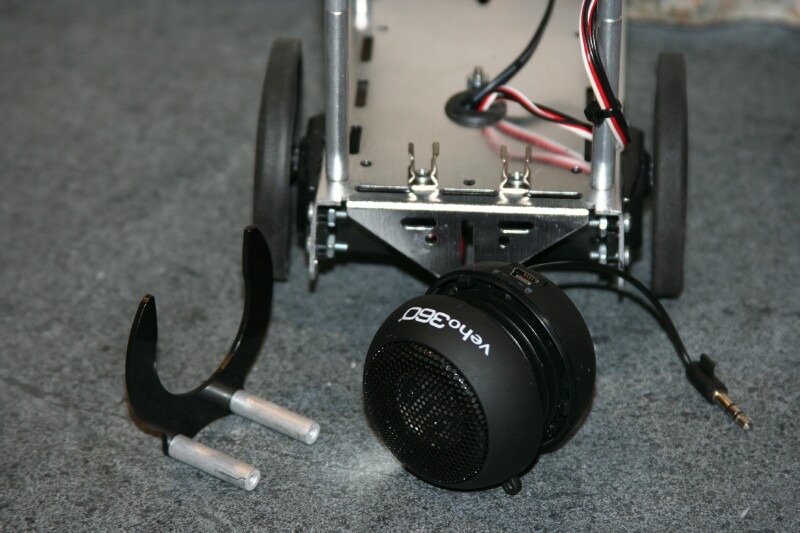

About two weeks ago I called Phil Pilgrim on my way home on a Friday afternoon with a little challenge: figure out a nice mount for the veho360 speaker on a PropBot! Both of us thought it could be a very simple laser cutter project. By Monday Phil had a FedEx package on the way with the final design. Wow! Now I have the perfect test platform for his upcoming speech synthesis work on the Propeller. If customers are interested we could make a little kit that includes these parts, too. Keep in mind there are many ways to mount the veho360 speaker on a Boe-Bot using Phil's design. I chose to drill a couple of new holes in the chassis front, one inch apart. My example is shown at the bottom of this post.

Here's a snippet from Phil's message.

I designed a bracket for those little hamburger speakers. It turns out that the bellows is plenty stiff to hold the speaker both vertically and horizontally. The bracket just snaps into the middle bellows fold, and the speaker can be rotated to any angle. I think the attached photos are mostly self-explanatory. To fill in some details:

1 ea. laser-cut bracket

2 ea. 1" x 0.25" (4-40) round standoffs (nylon or aluminum)

2 ea. Keystone #3567 stopless fuse holder clips

4 ea. 4-40 x 1/4" PHMS

2 ea. 4-40 nuts

Thank you Phil for doing this project. Additional photos and drawings from Phil are attached to this post. You are free to use them as you wish. Let us know if you are interested in getting these parts in a little kit - maybe I could find somebody in the office to put it together for us.

Ken Gracey

About two weeks ago I called Phil Pilgrim on my way home on a Friday afternoon with a little challenge: figure out a nice mount for the veho360 speaker on a PropBot! Both of us thought it could be a very simple laser cutter project. By Monday Phil had a FedEx package on the way with the final design. Wow! Now I have the perfect test platform for his upcoming speech synthesis work on the Propeller. If customers are interested we could make a little kit that includes these parts, too. Keep in mind there are many ways to mount the veho360 speaker on a Boe-Bot using Phil's design. I chose to drill a couple of new holes in the chassis front, one inch apart. My example is shown at the bottom of this post.

Here's a snippet from Phil's message.

I designed a bracket for those little hamburger speakers. It turns out that the bellows is plenty stiff to hold the speaker both vertically and horizontally. The bracket just snaps into the middle bellows fold, and the speaker can be rotated to any angle. I think the attached photos are mostly self-explanatory. To fill in some details:

- Material is 1/16" black Delrin. Mine took 14 seconds to laser cut (35W). 1/16" acrylic could also be used. (1/8" material is too thick.) Hole spacing is 1".

- The round standoffs are 1" x 0.25" (4-40), which I believe you stock. They are tall enough for the bottom of the speaker to clear the surface by about 0.1". For vertical mounting, one or both standoffs can be used.

- The clips for horizontal mounting are stopless 3AG screw-down fuse clips (Keystone #3567). BTW, these are really handy things to have around. I use them all the time for mounting stuff to the BOE-Bot.

- They grip the standoffs tight, yet it's easy to adjust things by sliding the standoffs through the clips.

1 ea. laser-cut bracket

2 ea. 1" x 0.25" (4-40) round standoffs (nylon or aluminum)

2 ea. Keystone #3567 stopless fuse holder clips

4 ea. 4-40 x 1/4" PHMS

2 ea. 4-40 nuts

Thank you Phil for doing this project. Additional photos and drawings from Phil are attached to this post. You are free to use them as you wish. Let us know if you are interested in getting these parts in a little kit - maybe I could find somebody in the office to put it together for us.

Ken Gracey

Comments

I'd think wiskers and IR sensors will be harder to mount at a useful height while using this setup.

Edit: Do you care which way the speaker is facing? I might try my hand at a design.

I've been thinking about what I'd do with the space behind the speaker and I'd add a wireless video transmitter and a cup to carry M&Ms. Without batteries the configuration I'm showing above is front-tipsy.

Ken Gracey

Back on topic, it's a very slick design, Ken was showing this off in the office on Monday. Nice job, Phil!

Ken Gracey

[Edit: .....unless there isn't anything of interest under the speaker on the PropBOE....in which case, ignore this entire message!

Like this?

Wish I could do this kind of thing every day. Havne't been productive today but it's certainly been a great day!

In your latest configuration, will the cord still reach if you flip the speaker around so it's more centered over the VGA connector? There will be less torque on the VGA connector's solder joints that way.

-Phil

Yes, there's plenty of cord. Remember that the speaker can also rotate in your handy little delrin keeper, providing up to an inch more of cord if needed. There is no cord torque in any of these configurations.

So, what else can you do with these fuse clips, 4-40 screws and a couple of standoffs? Can you make something snazzy like erco showed up above? Can you build a boat? How about a rocket?

Ken Gracey

The camera can slide up and down in the fuse clips to adjust the field of view.

Of course, you can go totally Dr. Seuss with them, too:

-Phil

Theodor Geisel would be so very proud.

Anything mounted this way will be adjustable in both pan and tilt axes.

-Phil

Ken Gracey

I'm sure Erco would move to P.T. in a flash if he knew about EdenSaw.

-Phil

I'm sure P.T. is nice. We have a PT Cruiser!

After ferrying across from Victoria, I biked through Port Angeles, then my derailleur exploded in the Hoh rain forest. Nice, helpful people up there in Forks, but a tad too wet for my tastes.

I was a Forks fan long before the Twilight movies came along.

Ken,

I had just been looking at the VGA connector on my Demo Board to see how it could be used to hold the Veho360.

I figure the VGA connector isn't likely to be used while the Propeller Boe Robot is roaming around so the threaded connectors on either side could be used as an attachment point or the connector itself in conjunction with an end of an old VGA cord. Kind of like the Fluke device uses the serial port to attach to the Scribbler robots. You'd still need a way of connecting the Veho to the re-purposed VGA cord end.

I didn't pursue the VGA option because I was concerned the nice thin VGA connector on the Prop BOE might be damaged with the added stress of holding the Veho360.

So yes, I do like these versions better, but I worry about the stress on the VGA connector.

I haven't tried an old wire coat hanger yet but this is my bailing wire version (okay, it's not bailing wire, it's old phone wire).

The stress on the VGA connector is mitigated by the through-hole anchoring pins, but there are limits, I suppose. That was the concern in my post #9, since the weight (albeit minimal) was leveraged out a ways.

Erco,

Forks gets waaaay more annual precip than we do: 160" vs. 19". But mainly, just for you, we have EDENSAW!, a wood-lover's paradise. There are even a few palm trees in town (hardy Mexican fan palms). But, yeah, I spent more than an hour today brushing 8" of snow from my flat-roofed shop in anticipation of the freezing rain that's supposed to follow. Now I've got aches in places I didn't know I had places. Oh, also, the women are all bundled up this time of year. Any "tan lines" are probably just from windburn.

-Phil

Erco ain't the only plywood lover around here. In fact, I'm going to come up there this spring and you are taking me to that store. I can envision lots of unique CNC uses with nice, solid-core plywoods. Around here it's all OSB and melamine with a few Baltic birch choices. I'm there, Phil, and I'm bringing a trailer.

Ken

-Phil

-Phil

-Phil

-Phil

-Phil