Looking for someone with Laser cutting capabilities for a prototype project

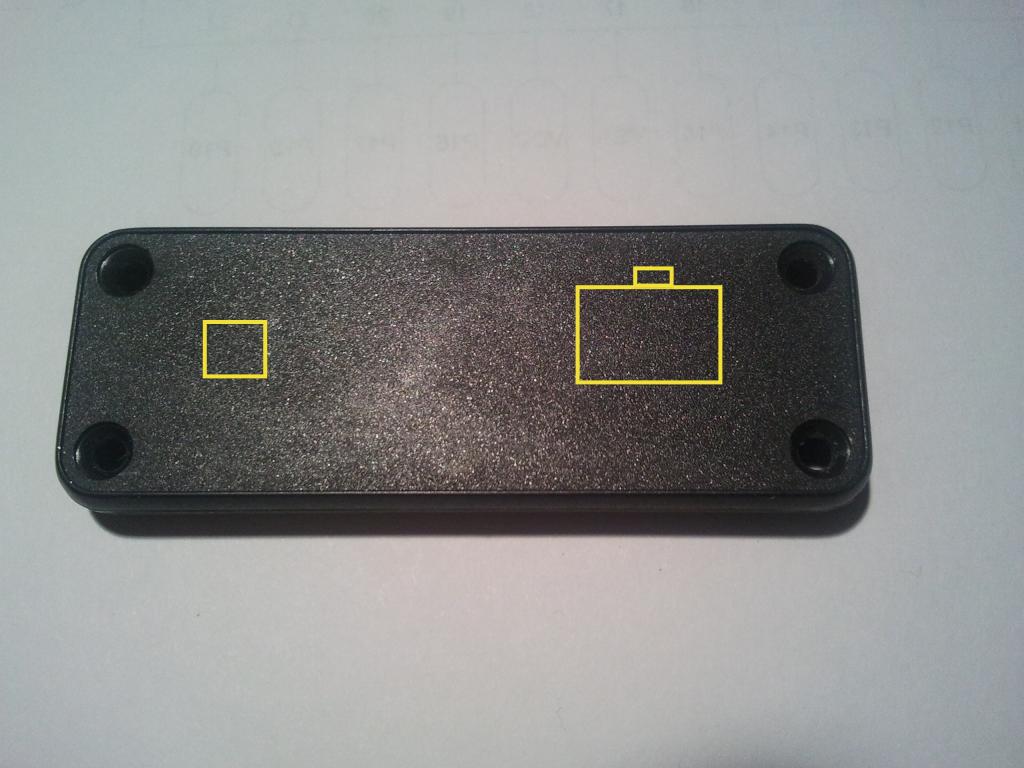

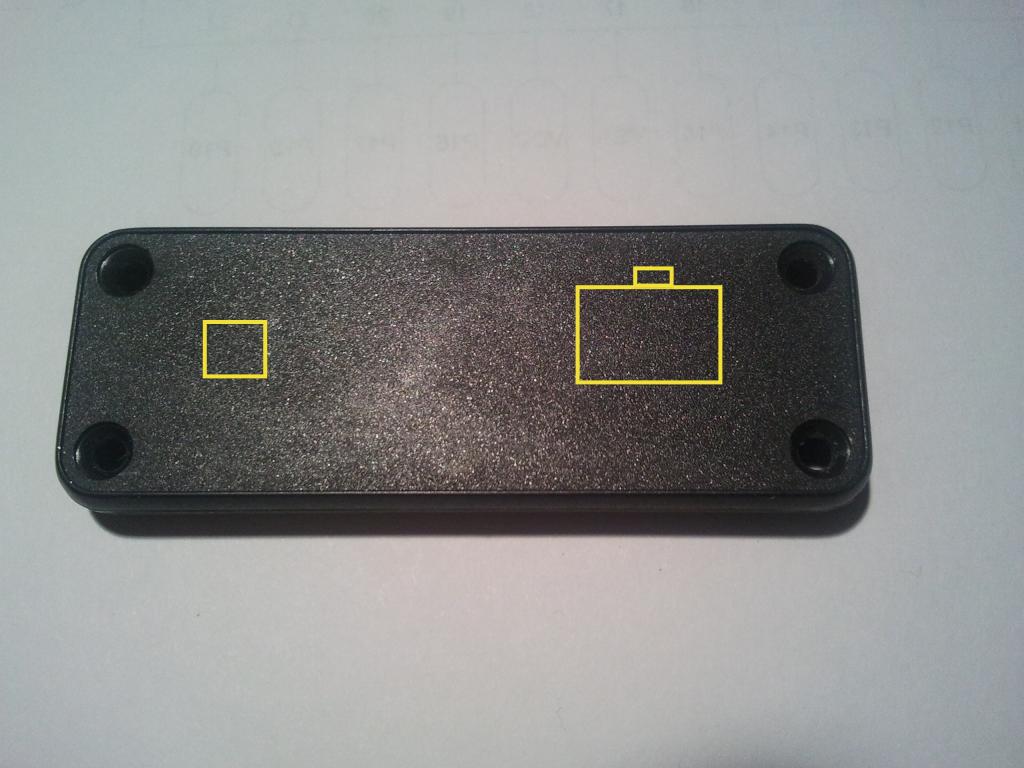

My project involves using a Hammond case with plastic end caps. I have attached a picture of the end cap with a simple drawing of an approximate shape of what I need cut out. The material is black ABS 2.5mm thick. I will provide a more detailed dimensional drawing to the person that will do the job.

Will the Laser cut this material ok and what type of edge will it leave?

Will the Laser cut this material ok and what type of edge will it leave?

Comments

http://mountainkingtech.com/

Bill

Ken Gracey

...Tiger

I just bought a laser cutter. With your ABS being only 2.5mm, I think I can cut that quite easily. I've already done a bit and it worked ok.

If you want, you can send me a sample of yours and I'll try it and see what it looks like.

Bill

Any suggestions to avoid this?

Try cutting them from the back, for one.

And I got them just to have a little fun making some of my projects around here. I actually bought one while I had an eBay bid on another. It was one of those bids that you thought was way too low to win... but I won it anyway... so now I have two lasers! :-) One is a small 40 watt desktop model and the other is a large 24"x36" 50 watt unit. Both are made by Redsail in China.

Bill