I love it when a plan comes together

Always nice when your hobbies manage to complement each other:

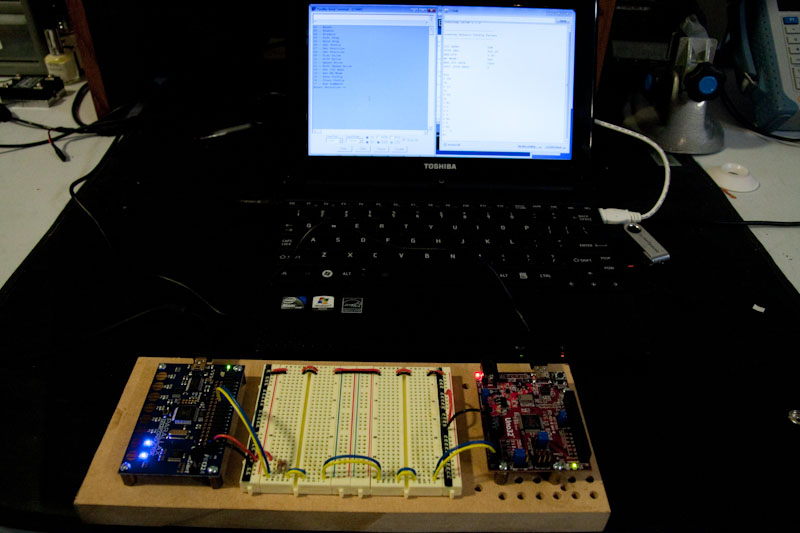

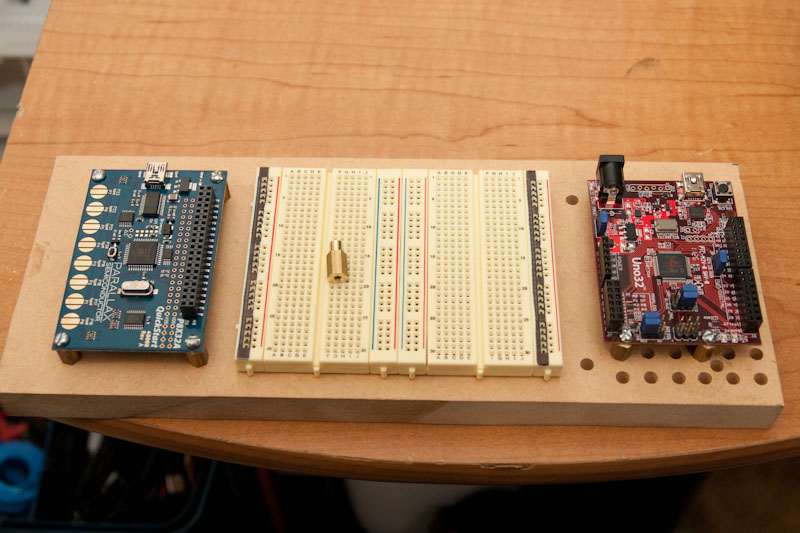

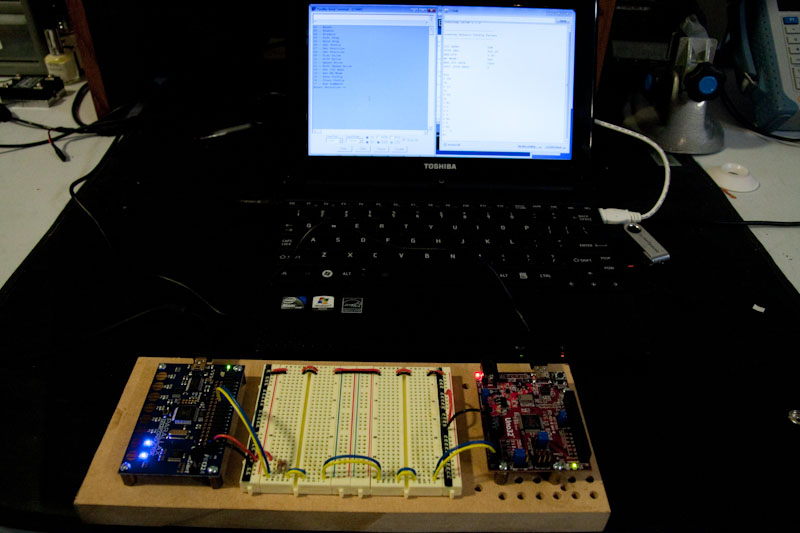

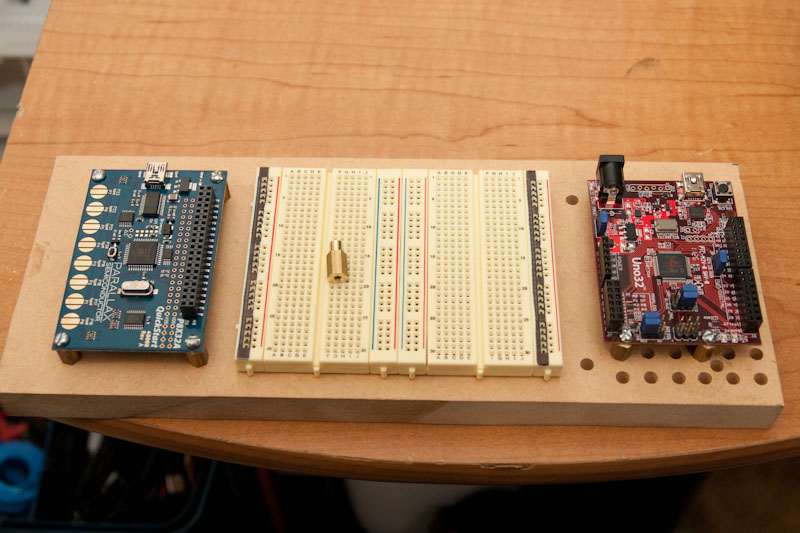

After messing with the Quickstart and Diligent Uno32 board I kept coming to the conclusion that it was a pain fighting the breadboards and cables and boards sliding around and pulling things loose. I wanted a way to hold the board and maybe some small development circuits and another board for coms testing that was easy to move from place to place. So I got the idea of a peg-board in MDF. Make little pins with hex standoffs attached and drill/tap them for 4-40's and layout a pattern that would allow me to get an Arduino or another Quickstart to mount onto it. Made the little pins last night on the lathe and turned them to be a *tight* fit in a drilled 3/16" hole. Then used the CNC mill to trim up the MDF and drill out the hole pattern on the left. The pattern was because I only had the hole layout for the Arduino, not the board dimensions so I wanted a little room to move it around. There is also a pattern to accept another QS board. So now I can trot upstairs with my little setup and sit in the livingroom and test code witout having to lug around a rats nest of loose boards.

It's always more work to do it than it seemed in our head planning it. Came out well though I think.

After messing with the Quickstart and Diligent Uno32 board I kept coming to the conclusion that it was a pain fighting the breadboards and cables and boards sliding around and pulling things loose. I wanted a way to hold the board and maybe some small development circuits and another board for coms testing that was easy to move from place to place. So I got the idea of a peg-board in MDF. Make little pins with hex standoffs attached and drill/tap them for 4-40's and layout a pattern that would allow me to get an Arduino or another Quickstart to mount onto it. Made the little pins last night on the lathe and turned them to be a *tight* fit in a drilled 3/16" hole. Then used the CNC mill to trim up the MDF and drill out the hole pattern on the left. The pattern was because I only had the hole layout for the Arduino, not the board dimensions so I wanted a little room to move it around. There is also a pattern to accept another QS board. So now I can trot upstairs with my little setup and sit in the livingroom and test code witout having to lug around a rats nest of loose boards.

It's always more work to do it than it seemed in our head planning it. Came out well though I think.

Comments

'

I have that rats nest on my bench now...I don't dare move anything until I get the drawing revised.

'

This can become a real pain when I need to work on something else.(no bench space left)

'

Thanks for sharing

I've always used thick cardboard to mount different boards together like this.

(Just place a few M3 screws in the mountingholes on the boards, place it on the cardboard and apply force.. Then add a washer and nut on the other side)

This also works with cardboard boxes... One that's 6 x 8" or larger, and maybe 2" deep is nice. Mount the boards on the inside, add a couple of baggies for components, a holder for AAs and suddenly a self-contained workbox.

Doesn't look as neat, though.

Hey! Cool! Bring it over to my side of the line! (I'm in Piper.)

--Bill

Bill - it may be coming over the border a few days a week. My day job is at KU Med.

It's a small world. My daughter did her post-doc at KU Med.

I noticed your mill and lathe mentions. Do you belong to any of the home machinist's forums?

--Bill

The Home Machinist forum for me. Same name. My pseudonym is seal killer. I think I am a member of the homeshopmachinist. I'll look for you over there.

--Bill