Does pre-drilled copper clad board exist?

Oldbitcollector (Jeff)

Posts: 8,091

Oldbitcollector (Jeff)

Posts: 8,091

Brainstorming this morning on ways to make home pcb fabrication quicker and easier.

Has anyone ever seen pre-drilled copper clad pcb? The difference would be that ALL the copper holes would be connected together until it was prepared for use in a project.

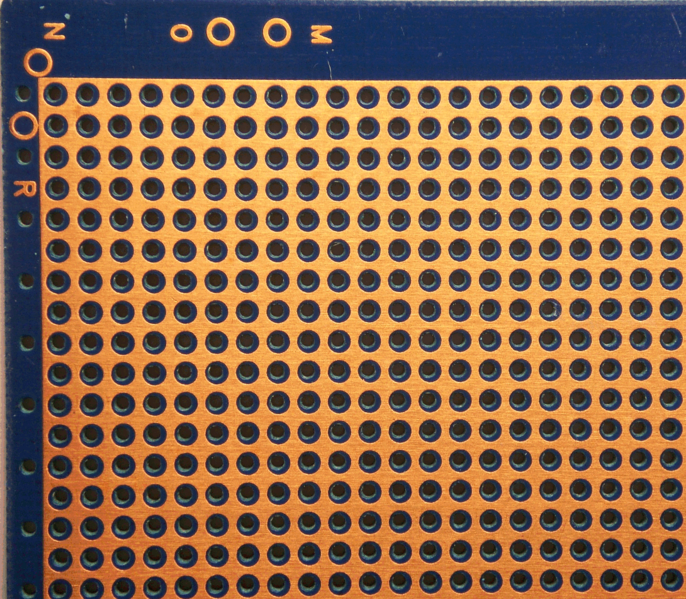

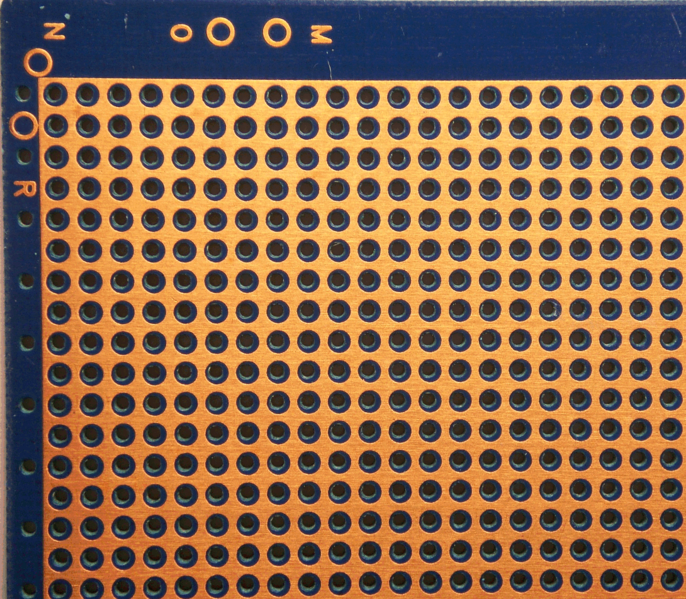

Edit: A little more searching turned up this photo. Never seen this stuff. Anyone got a source?

OBC

Has anyone ever seen pre-drilled copper clad pcb? The difference would be that ALL the copper holes would be connected together until it was prepared for use in a project.

Edit: A little more searching turned up this photo. Never seen this stuff. Anyone got a source?

OBC

Comments

Could remove the secondary process of drilling after you are done etching a board.

IIRC, a permanent marker can also be used to "draw" the circuit before etching.

It looks like Digikey carries a product like this, but I am unable to confirm it.

OBC

The holes on the board in the photo aren't connected together -- or to anything. That's just a groundplane. What you really want is a board with plated holes, right?

-Phil

What you're looking for are boards for RF applications, so I'd look at sources selling protoboards for hams and other radio jocks. Vector is still a good source for these, but you probably already know their stuff is anything but cheap. Both Digikey and Mouser carry a good selection of the Vector prototyping boards.

-- Gordon

As long as you're not producing multi-panel boards 20"x30", a little 5"x7" CNC should suffice. And since you're only routing off a thin layer of clad, the steppers don't need a lot of horsepower. Standard size 17 motors should do, and with microstepping they ought to provide good resolution. For that matter, the same machine could automate isolating the clad in these groundplane clad boards OBC is looking for.

There are some plans out there, but I've never really looked into it.

-- Gordon

One of the reviewers' comments, though, pretty much dovetails with my thinking:

-Phil

http://www.twinind.com/subcategory/Plated-Through-Holes

http://www.twinind.com/subcategory/plated-through-Holes-single-power

http://www.twinind.com/subcategory/plated-through-holes-dual-power

http://search.digikey.com/us/en/products/B3426D/B3426D-ND/354320

http://search.digikey.com/us/en/products/B3429AD/B3429AD-ND/354324

etc

Look for 'stripboard cutter' for ideas. There's also the chisel type, described here in Ron ("Mr. Stripboard") Hackett's Web site

http://www.jrhackett.net/tools.shtml

-- Gordon

-Katie

-Phil

Depending on the number you need, you can make them yourself, specially if no plated holes are needed, just look for someone who does 2 side boards without PTH