Tachometer resolution

I want to embed a tachometer in my project and I am bumping up against an issue of resolution. I have a Rotax engine that has 12 poles on the flywheel alternator. The tach wire generates an AC signal with 6 cycles per revolution.

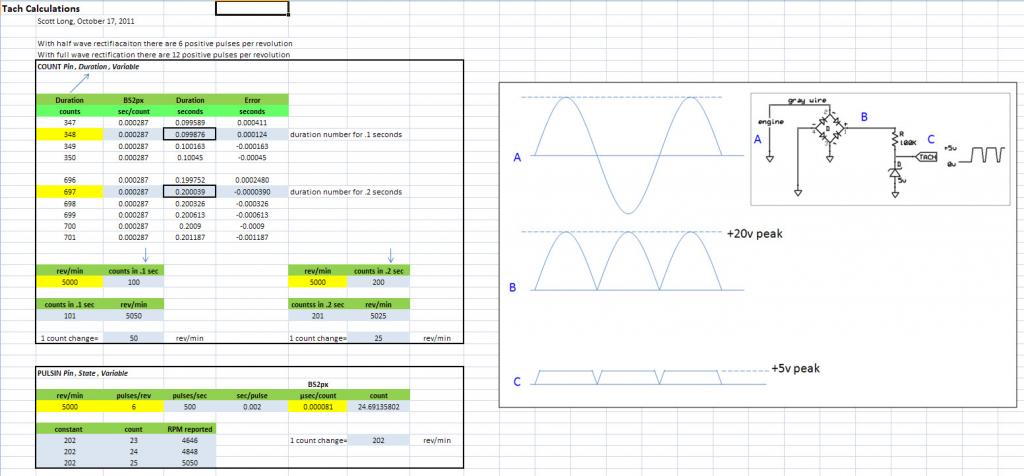

The attached spreadsheet (image) shows that if I use "COUNT" with 12 pulses per revolution and wait around for 0.2 seconds, the resolution is 25 rpm. Waiting around and counting for >0.2 seconds is not acceptable as I have lots of other tasks for my BS2px to do.

If I use "PULSIN" with 6 pulses per revolution I can only get a resolution of 202 rpm.

Anyone have a solution to get better resolution? Thanks for the help. -Scott

The attached spreadsheet (image) shows that if I use "COUNT" with 12 pulses per revolution and wait around for 0.2 seconds, the resolution is 25 rpm. Waiting around and counting for >0.2 seconds is not acceptable as I have lots of other tasks for my BS2px to do.

If I use "PULSIN" with 6 pulses per revolution I can only get a resolution of 202 rpm.

Anyone have a solution to get better resolution? Thanks for the help. -Scott

Comments

Welcome to the forums! You have responded to two posts that were 5 years and 12 years old.

Sounds like the SX did everything you wanted. Would you like to share your code so others can benefit from it?