RoboSketch - Propeller controlled Etch-a-Sketch

JasonDorie

Posts: 1,930

JasonDorie

Posts: 1,930

While this is much simpler than Mike Park's PropEtcher (see http://www.youtube.com/watch?v=MgyZgqImAHA) it was as much a test of my CNC machine cutting acrylic as it was making an automated Etch-a-Sketch.

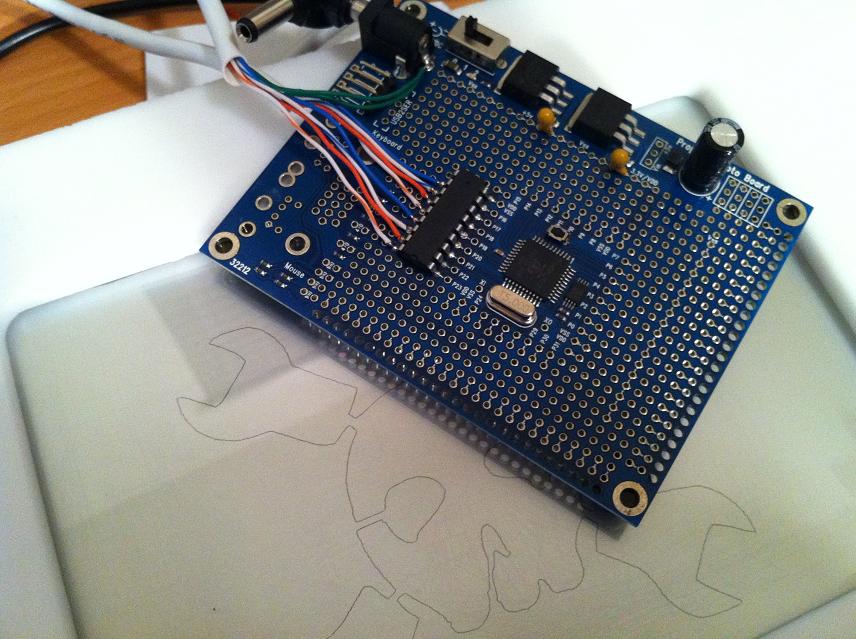

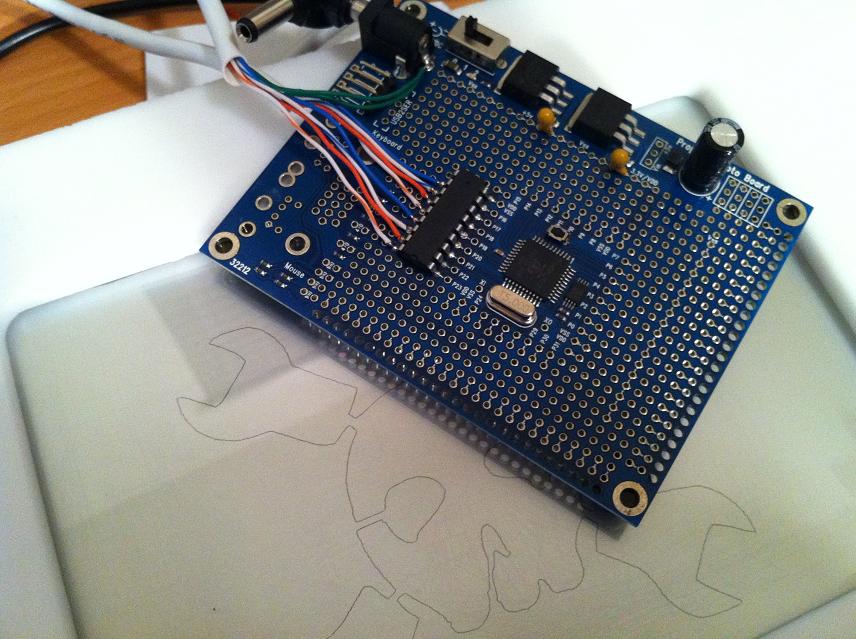

The circuit is incredibly simple: it's a Protoboard and a single darlington array to control a pair of unipolar stepper motors (the ones Parallax sells here: http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/stepper/List/0/SortField/4/ProductID/65/Default.aspx)

I used my home-built CNC router to cut the face plate and gears from a single piece of acrylic and replaced the existing red frame with my new CNC'd one.

The software is written entirely in SPIN and supports a simple "goto" function that takes an X & Y coordinate. It uses a Bresenham line algorithm to control the step rate of the motors. With gearing and using 1/2 steps, the usable screen area is about 800 x 600 units.

Here's a video of it in action: http://www.youtube.com/watch?v=W3iPjJfIIOs

...and another of it drawing the Hack-a-Day logo: http://www.youtube.com/watch?v=-MNqW1GT4nc

Code is attached.

The circuit is incredibly simple: it's a Protoboard and a single darlington array to control a pair of unipolar stepper motors (the ones Parallax sells here: http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/stepper/List/0/SortField/4/ProductID/65/Default.aspx)

I used my home-built CNC router to cut the face plate and gears from a single piece of acrylic and replaced the existing red frame with my new CNC'd one.

The software is written entirely in SPIN and supports a simple "goto" function that takes an X & Y coordinate. It uses a Bresenham line algorithm to control the step rate of the motors. With gearing and using 1/2 steps, the usable screen area is about 800 x 600 units.

Here's a video of it in action: http://www.youtube.com/watch?v=W3iPjJfIIOs

...and another of it drawing the Hack-a-Day logo: http://www.youtube.com/watch?v=-MNqW1GT4nc

Code is attached.

Comments

(Show it making the Spirograph pattern.)

Does this mean your back to writing code for Quadracoppters?

Ron

It's a cinch to get on then.

http://hackaday.com/2011/08/05/etch-a-sketch-automatically-draws-a-tribute-to-hack-a-day/