Magnetic couplers

I can't find too much info about how to approach this scientifically, I have been doing this by the seat of my pants using these - http://www.kjmagnetics.com/proddetail.asp?prod=B222G-N52 - and these - http://www.kjmagnetics.com/proddetail.asp?prod=B441

I find it hard to figure out based on the info which would give me the ideal coupler. Some things I don't understand are :

What causes clutch action, whether more or less magnets is better, or spacing from center affects this.

Which magnet specs apply when calculating overall pull of a specific magnet to another.

Anyone else out there tried this?

I find it hard to figure out based on the info which would give me the ideal coupler. Some things I don't understand are :

What causes clutch action, whether more or less magnets is better, or spacing from center affects this.

Which magnet specs apply when calculating overall pull of a specific magnet to another.

Anyone else out there tried this?

Comments

have you looked at any old patents on magnetic clutches? You can do a simple search of US patents by looking here:

http://patft.uspto.gov/netahtml/PTO/search-bool.html

Sometimes patents explain the rationale behind their particular designs.

http://www.usplastic.com/catalog/default.aspx?catid=629&parentcatid=722

Magnetic drive pumps are kind of expensive but maybe you could find an exploded diagram of one.

The 3d pdf is generated by alibre, not sure it will work for everyone. It doesn't include the lid and base and other driven gear, for clarity.

I take it back.

Magnetic drive pumps are expensive unless you're trying to build your own.

It's one thing if you're doing this for the journey but if you just want to get something that works I can't see building your own costing less than buying one.

I'd think this is at least half the problem of designing a pump.

It looks like the motor is for a rc airplane. Do you need to worry about cooling the motor?

Are you sure you want to build your own?

It sure seems like you're taking the hard way of solving your problem. (Not that that is necessarily a bad thing.)

Duane

I'm pretty sure motors are usually designed for a particular task. I'd think pumping water would be much different than spinning a propeller in the air. I hope you understand electric motors better than I do because I just don't see this working well.

(BTW, I always like it when people tell something I'm doing wont work. It makes me work harder to prove them wrong. I hope you prove me wrong. (But not at the expense of not solving your problem.))

Duane

I agree with Duane. If by rc motor you mean the type of motor used for radio control airplanes, etc. then I think you probably should look for a different kind of motor, especially if you absolutely need to use a centrifugal pump. Can I ask at what pressure, temperature, and fluid flow rate you're trying to pump? Perhaps a centrifugal pump is not the best way to go. Perhaps a diaphragm pump or perstaltic pump might work better for the brominated water. Perstaltic pumps can use different types of tubing that can take all kinds of nasty chemicals, and the fluid never has to contact anything but the tubing. They are great for lab work and it's possible to build your own.

http://en.wikipedia.org/wiki/Peristaltic_pump

'

Take a look at water Analyzers.(Mixing-Stiring motors and assy's.)

'

Hack,Honeywell,Rosemount Analytical,ABB, are just a few to search for.

'

I have some info on this approach at work,But it would be late Monday before I could reply back.

'

I hope this helps.

'

Peristaltic pumps work well at keeping the fluid away from the metal parts untill the tube in the pump wears outs and then you have a mess.

'

If you go with a Peristaltic pump, Mount it below any thing you don't want to get wet.

This pump's description says the tubing lasts 40 hours.

I have a working protoype (shaft type) that pumps 1-2 gpm at about 4000rpm, using 1.5amps at 24V. You have to pick and choose your motor. I am using a 740kv motor, an although its not a perfect match, it works well. You have to understand, I can get a complete motor cheaper that I can get custom windings. The right kv would be around 300. I can adjust my impeller size to match my motor. I found a good industrial motor that matches better, and guess what, they only keep about 15 on hand, with a 10-12 week leadtime.

On another note, there are space restrictions, and cost restrictions. Farmers used to paying $25-30 for a pump won't buy a $300 pump no matter how good. One thing you find when looking for motors and pumps, is that the cost on some these pumps is out of hand. I have had a few people tell me that I should use an off the shelf pump, and I have spent days looking for one, but none fit the bill. I know this will be met with some skepticism. Another note, if it is on alibaba, I don't want it.

What I am doing is not a true centrifugal, but sort of a hybrid I don't feel like showing here.

So far I have been doing my prototyping on a cnc router.

"not a true centrifugal, but sort of a hybrid I don't feel like showing here."

'

Now What?

I think it's safe to assume you know more about electric motors than I do.

Have you looked at some of the magnetic drive pumps to see how their couplings work?

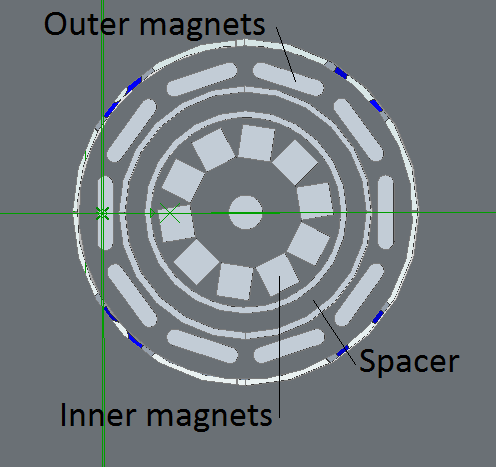

I'm pretty sure you want both sets of magnets relatively close.

Do the magnets need to be configured as inner and outer rings?

Or would two plates with magnets work. Kind of like clutch plates in a car. You could use thrust bearings to hold the plates away from the separating wall.

Well, no, but I've often wondered about magnetic drives.

I just looked through my college physic text in an attempt to find some equations describing the attraction between magnets. I couldn't find anything useful for this case. All the equations I found relate magnetic fields to induced currents.

Duane

It's true that silicone tubing will not work for bromine. But Masterflex C-flex tubing is a common peristaltic pump tubing and is rated as Excellent for Bromine.

http://www.grayledge.com/files/MasterflexTubingChemicalCompatibilityTables.pdf

If you decide to use magnetic coupling, be aware that the magnets will capture any tiny bits of ferrous metal that might happen to be in the fluid, so there's a possibility of the unit developing a buildup that could be harmful to the pump. Consider placing magnets upstream of the pump intake to capture these sorts of particles.

Lawson

I assume you mean replacing the brushless rotor with my own.

One thing I don't have a good understanding of is the effect of the outer iron ring. What happens without iron?

One hypothesis I do have is that If you had two couplers with an equivalent amount of magnets, one with the magnets operating with a 0.5" radius, the next with a 1", I suspect the 0.5" will produce more slipping clutch torque, and the 1" will produce more peak torque.

Iron in magnetic circuits acts a lot like wire in an electrical circuit. Unfortunately the "wire" and "insulation" available for magnetic is fairly poor, so while most of the magnetic field will follow the iron core, enough flows outside of the iron core to often cause problems.

Not really, the 1/2 inch radius case will just produce half the torque. (assuming the same magnets and air gap thickness. I.e. same total flux in the air gap.) To get significant average torque while slipping you'll need to add a copper plate or shorted copper windings to one half of the coupling. The extra copper will then generate eddy current drag when the coupling slips. In fact, if you can get the eddy current drag high enough, (and can tolerate some slippage) you may only need magnets on one side of the coupling.

Lawson

Is the copper ring size important? I hadn't thought of doing it that way. In my situation could I place a thin ring around the outer magnets? ie(1/4 height, 1/16 width, 1.2 diameter?)

The biggest trouble with using an outrunner is that assembly of the system is difficult. You have to cantilever your ring up into the space and use bushings, and the tolerances are too critical, I think. I went rounds with it, decided against it. I can't find a suitable inrunner. The coils shown are from a nema 17 size bldc, and would work, but I can't find similar coils cheap enough.

I bet your torque while slipping is coming from two sources. First, eddy currents in the magnets themselves due to the nickle plating. Second, your coupling isn't running at steady state when it's catching up to the motor.

For the copper ring you want it wider than the poles it's facing. I'd also recommend backing it with an iron ring to help complete the flux path back to the magnets. A good test to see if the iron backing ring is thick enough is to see if a sewing needle will stick to the back of the ring. (when it's fully assembled with the drive magnets of course) Picked that up from a motor making mailing list I followed for a while.

Another thing that might help is that most hobby motors are wired Delta. If you carefully re-arrange the connections inside the motor it can be changed to a Y winding. This will reduce the speed by sqrt(3)/3 increase the resistance 3x and reduce the maximum power output of the motor unless the input voltage is raised by sqrt(3)

Lawson

I experimented some with adding hall sensors outside for sensored control. Horizon Hobbies park 480 is so tight(iron ring wise) I could hardly pick up the magnets outside the ring. Interestingly enough, I had more trouble getting reliable starts from that motor. I think it is supposed to have the most power for its size.

I tried it here with some magnets in a copper pipe.