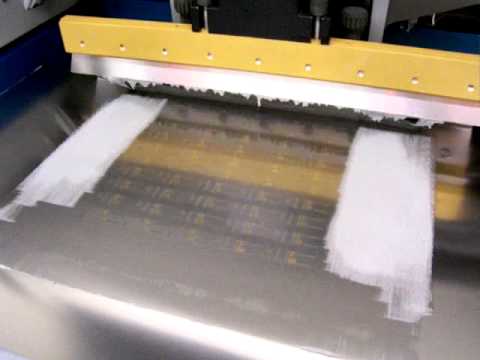

Parallax's New Automatic Stenciling Machine

Yes, another new piece of equipment came 'online' today! - (actually yesterday, but my camera batteries were dead)...

Although, we've had this Machine for a while, Manufacturing has been so busy that we haven't had a chance to get it fired-up and connected to our PnP and Oven line. The Talent Pool in Mfring made it happen - Yay Mfring Talent Pool!

(Up until now, we've been "hand stencliling" - but no more - higher throughput and better quality!)

Visually, it's not really that impressive of a video. However, what it does for us is eliminates stenciling the panels by hand - which helps drive down cost and increases consistency and quality.

-Matt

Although, we've had this Machine for a while, Manufacturing has been so busy that we haven't had a chance to get it fired-up and connected to our PnP and Oven line. The Talent Pool in Mfring made it happen - Yay Mfring Talent Pool!

(Up until now, we've been "hand stencliling" - but no more - higher throughput and better quality!)

Visually, it's not really that impressive of a video. However, what it does for us is eliminates stenciling the panels by hand - which helps drive down cost and increases consistency and quality.

-Matt

Comments

You mean Mr. Li-ion had dead batteries??? I think we all need to ponder this situation........

Back on subject - this is cool!! As a loyal customer, I fully support and appreciate your ongoing passion for driving down costs and increasing quality!!

@Mindrobots - That thar's what ya' call ironic!

Yes, that is a passion (driving down costs), yet still striving for the best quality possible. Sometimes offering several different products of varying quality (the new Prototype Ping Stands that the Contest Winners are trying out, for example), is a solution.

Inexpensive and functional? The Acrylic Stand. Top Quality, and Shiny to boot? Machined Aluminum Stand is the answer.

-Matt

That's probably the most unsexy -- yet eminently useful -- machine in your shop. I mean, what does it do besides smear gray goop on your PCBs?

What steps do you have to take to preserve the pot life of the gray goop? Do you have to clean everything after use and seal the goop back in the can, or can you let it sit overnight and have it ready to use the next day without the goop turning into concrete?

-Phil

Probably true, Bomber. The frequency of use is low, but when you stencil you better get it right. The machine provides an even pressure to properly distribute the solder paste.

When our humans do this task only a couple of them have been able to master it, causing great frustration among the team or a dependency on a couple for this task. If it's not scalable, it's not mass production.

Ken Gracey

-Phil

Another advantage is this:

The manual method was on a table, with a manually operated hinged stencil frame. Each board had to be precisely placed (by hand) into an exact location, then the stencil lowered, then the squeegee picked up and wiped. Then the squeegee set down, then the stencil lifted up, and then the board lifted out of the device and placed on a table with a bunch of other "pre-stenciled" boards awaiting insertion into the PnP conveyor.

With this machine the operator simply loads a blank board into a slot at the beginning of the production line, and (almost) never has to touch it again until it comes out the oven at the other end.

So while the "wiping" action of the machine is certainly slower, the "overall operation" time is reduced, which provides more time for Quality checking, etc.

-Matt