Help with power down save value to EEPROM

In my project I have successfully been able to save a value to the EEPROM after the Propeller detects a power down. I would like to share with everyone here my example but also have a question about a small glitch.

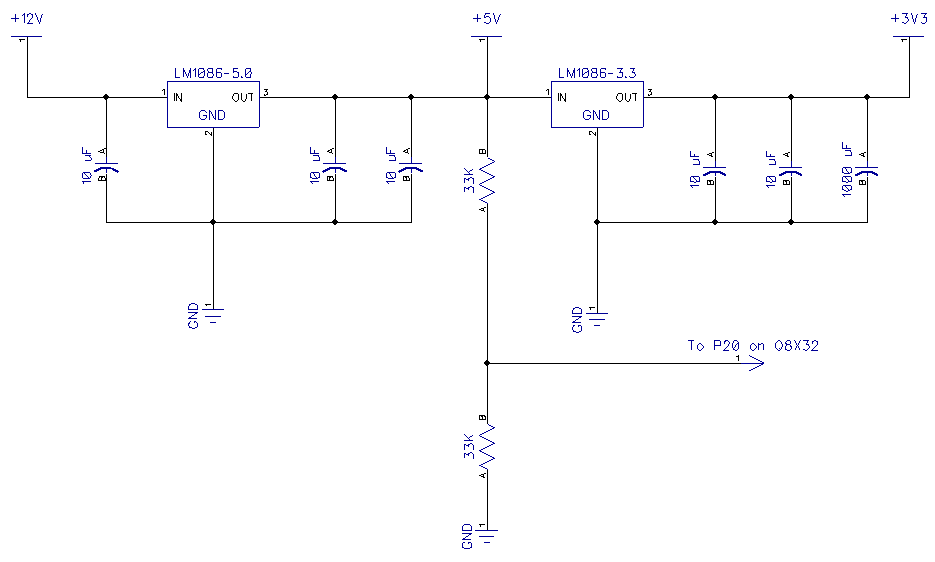

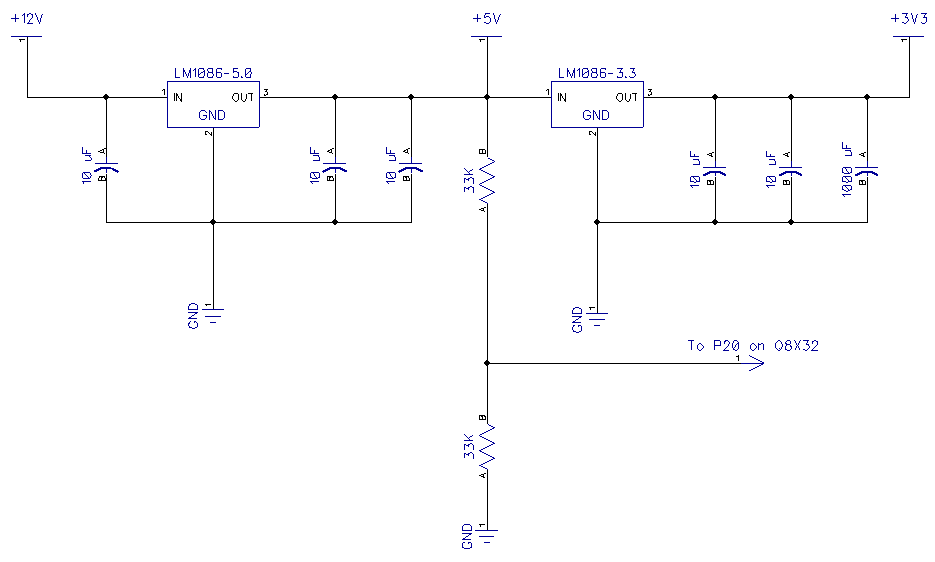

I am using the Propeller Proto board (non USB version). This board comes with a 1000 uF capacitor that is un-connected. I connected it to the 3.3 volt bus. I also added 2 resistors as a voltage divider from the 5 volt supply bus. I tie the center of the divider network to P20 on the Propeller. See attached schematic.

My Logic Analyzer connections are: I2C CLK, I2C DATA, P20 Input from divider, 3.3 volt supply.

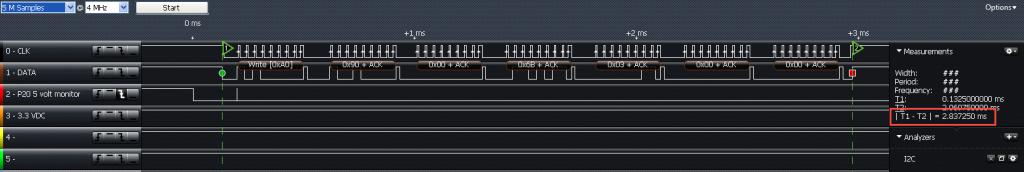

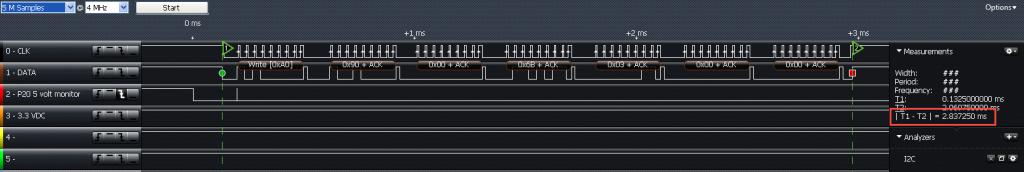

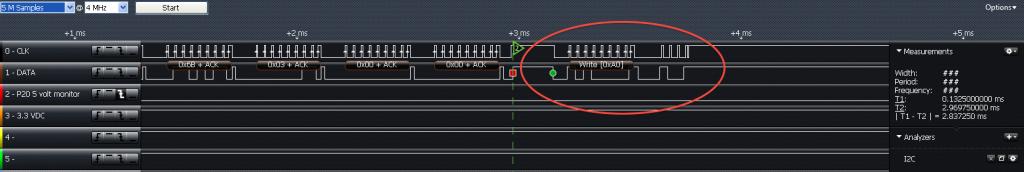

Here I'll show you a Logic trace taken during the power down sequence. In this trace I have shown 2 green markers that indicate the start and stop of the I2C routine writing to the EEPROM. I have placed a red box around the time showing that it takes approx 2.84 mS to write a long to the EEPROM.

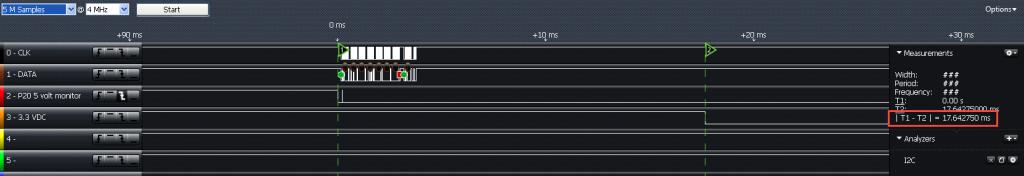

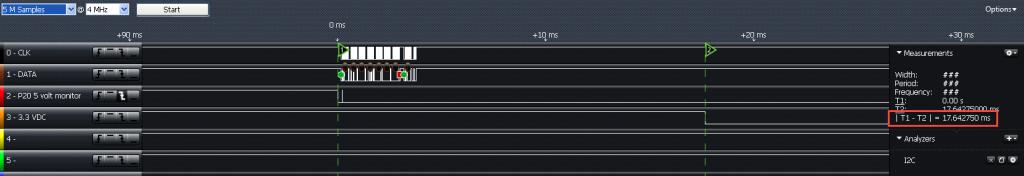

Next is a wider view of the Logic trace showing the time relationship between when P20 goes to logic low and when the 3.3 volt bus goes to a logic low value. Note that the time it takes is approx 17.64 mS.

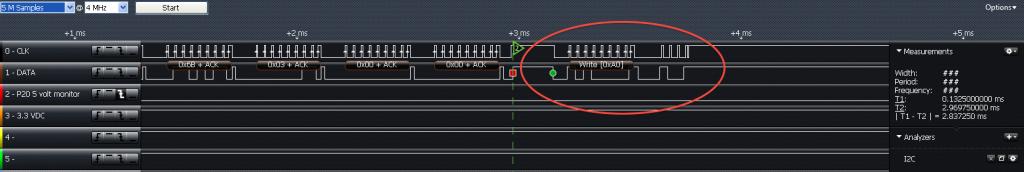

Now here is where my glitch question comes in. In this trace you will notice that the I2C object is trying to write again to the EEPROM. I think this has to do with the way I have my loop logic written but I don't know how to correct it. I added "repeat 1" to the loop to try and make it only write 1 time but that didn't help. Here is the Logic trace showing what I am talking about. I have circled in red where it starts to try and write but you can see that it does not finish. Maybe the EEPROM Vcc is to low by then? I don't know. All I know is that I want it to only write the one time and quit.

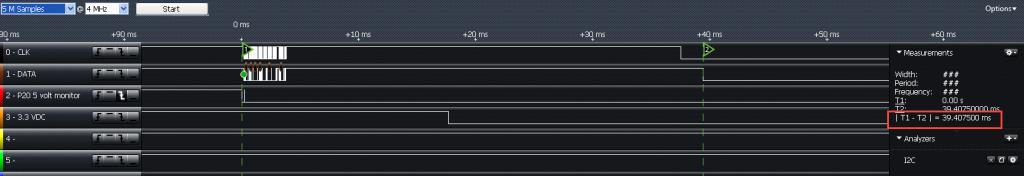

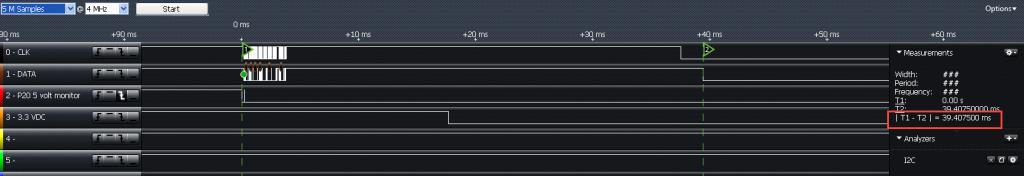

And here is an even wider Logic trace showing the timing relationships when all the pins go low after the detection of power down. You can see that the overall time is approx 39.4 mS.

Here is my code:

I am using the Propeller Proto board (non USB version). This board comes with a 1000 uF capacitor that is un-connected. I connected it to the 3.3 volt bus. I also added 2 resistors as a voltage divider from the 5 volt supply bus. I tie the center of the divider network to P20 on the Propeller. See attached schematic.

My Logic Analyzer connections are: I2C CLK, I2C DATA, P20 Input from divider, 3.3 volt supply.

Here I'll show you a Logic trace taken during the power down sequence. In this trace I have shown 2 green markers that indicate the start and stop of the I2C routine writing to the EEPROM. I have placed a red box around the time showing that it takes approx 2.84 mS to write a long to the EEPROM.

Next is a wider view of the Logic trace showing the time relationship between when P20 goes to logic low and when the 3.3 volt bus goes to a logic low value. Note that the time it takes is approx 17.64 mS.

Now here is where my glitch question comes in. In this trace you will notice that the I2C object is trying to write again to the EEPROM. I think this has to do with the way I have my loop logic written but I don't know how to correct it. I added "repeat 1" to the loop to try and make it only write 1 time but that didn't help. Here is the Logic trace showing what I am talking about. I have circled in red where it starts to try and write but you can see that it does not finish. Maybe the EEPROM Vcc is to low by then? I don't know. All I know is that I want it to only write the one time and quit.

And here is an even wider Logic trace showing the timing relationships when all the pins go low after the detection of power down. You can see that the overall time is approx 39.4 mS.

Here is my code:

con

_clkmode = xtal1 + pll16x

' _xinfreq = 5_000_000

_clkfreq = 80_000_000

MS_001 = _clkfreq / 1_000

RS = 9 ' 1

RW = 10 ' 2

E = 11 ' 3

DBLow = 12 ' 0

DBHigh = 15

PWR = 20

EE_DEVICE_ADDR = $A0

EE_BASE_ADDR = $9000

con

#1, HOME, #8, BKSP, TAB, LF, CLREOL, CLRDN, CR, #16, CLS ' PST formmatting control

' 0.003515185598214 ' multiplier for inches / pulse

obj

term : "fullduplexserialdp" ' for terminal output

level : "jm_grayenc2" ' 2-bit, graycode encoder

kp : "Keypad_encoder" ' keypad driver object P0 - P7

vfd : "LCD_Nx2" ' VFD driver

simp : "Simple_Numbers_plus"

i2c : "Basic_I2C_Driver_1"

var

pub main | newlevel, oldlevel, Pressed_Key

term.start(31, 30, %0000, 115_200) ' start terminal for test

pause(2000)

term.tx(CLS)

dira[PWR] := 0

i2c.initialize(28)

level.init(16, true, 0, 1707, i2c.ReadLong(i2c#BOOTPIN, EE_DEVICE_ADDR, constant(EE_BASE_ADDR + $0))) ' detented encoder on p16/p17

vfd.Init( E, RS, RW, DBHigh, DBLow )

kp.start(4, 4, 0, 4, @table) ' start keypad driver

pause(1)

vfd.clear ' clear vfd screen

term.str(string("Table Controller", 13))

term.str(string("Version 0.07"))

vfd.PrintStr(string("Table Controller"))

vfd.SetRowCol(2, 0)

vfd.PrintStr(string("Version 0.07"))

pause(4000)

vfd.clear

term.tx(CLS)

term.tx(LF)

term.str(string("Press PROG for Menu"))

vfd.SetRowCol(2, 0)

vfd.PrintStr(string("Press PROG for Menu"))

pause(500)

repeat

oldlevel := newlevel ' setup to detect change

term.tx(HOME) ' display it

vfd.SetRowCol(0, 0)

vfd.PrintStr(string("Position: "))

term.str(string("Position: "))

vfd.SetPos(16)

vfd.PrintChr($22)

newlevel *= 3515

newlevel /= 100

term.decdp(newlevel, 4)

vfd.SetPos(10)

vfd.PrintStr(simp.decf(newlevel, 4))

repeat

if ina[PWR] == 0

repeat 1

i2c.WriteLong(i2c#BOOTPIN, EE_DEVICE_ADDR, constant(EE_BASE_ADDR + $0), newlevel)

newlevel := level.read ' poll encoder

until (newlevel <> oldlevel) ' until it changes

pub pause(ms) | t

t := cnt

repeat ms

waitcnt(t += MS_001)

dat ' keypad translation table

table byte "1", "2", "3", "S"

byte "4", "5", "6", "R"

byte "7", "8", "9", "E"

byte "N", "0", "P", "X"

' Keypad layout

'

' 1 2 3 Start

' 4 5 6 Prog

' 7 8 9 Set

' - 0 + Stop

Comments

repeat if ina[PWR] == 0 repeat 1 i2c.WriteLong(i2c#BOOTPIN, EE_DEVICE_ADDR, constant(EE_BASE_ADDR + $0), newlevel) abort newlevel := level.read ' poll encoder until (newlevel <> oldlevel) ' until it changesIs that the proper use of that command?

I posted a PASM object (http://obex.parallax.com/objects/765/) that monitors a 60-Hz signal from a power transformer and clears a variable to 0 when the power fails.

It does this within 1/120 of a second and combined with a large filter capacitor on the Propeller's power supply, gives plenty of time to save variables to EEPROM.

Good Luck,

Don

Excellent and timely post with real world visual time base of power loss vs. eeprom writes times.

From my initial testing and discovering feedback through the PPB regulators, I am somewhat surprised to see your divider sense line at P20 drop to 0v with no blocking diode to the left node at the 1000uF cap.

In the near future I will be testing circuits using supercaps, backup battery and/or auto powerdown with latching mosfet methods.

I just purchased a Tektronix 2022C to R&D my options with save on detected power loss.

One question as to your regulator circuit and my findings I never did get a response on in my thread.

Will feedback through the PPB regulators, once power drops - eventually compromise these regulators?

Possible solution: Schottky diodes to block feedback.

Without schottky diodes to block feedback, I have read it may shorten both regulators usable life. I also question how much of the cap stored 3.3v these regulators would consume in reverse feedback; thereby reducing the efficiency of last gasp reserve. There are many threads here that discuss cap storage in R/C hold up time verses load current. Just not many proven circuit examples used long term.

This blocking solution brings in another issue with a schottky diodes voltage drop eating .3v (50%) of the potential headroom.

One option here is to swap out the regulators for an LM317(adjustable) in order to compensate the diode drop and return the Vdd back to 3.3-3.6v in the storage cap for more save time.

I have also read suggestions to lift the reg’s ground legs and insert another diode there to cancel out the diode drop on the output. I just do not look forward to removing the proto board reg’s or cutting traces on the board.

I have a Newark order coming next week with supercaps, mosfets and schottky’s. This is my last hurdle for this prototype project.

I hope to prove my circuit with my own data like what you have posted here. That sure takes the mystery out of the unknowns.

Much appreciated!

$0