IMPORTANT: Save those Bags (and the conductive foam too)!!!

When Parallax ships a product it is shipped in either a grey, (sometines) antistatic bag or a pink bag.

DON'T THROW THOSE BAGS AWAY!!!!!!!!!!!!!

(I THINK I emphasized that enough)

Those bags have other uses. For example you could store your ICs in one of the antistatic bags to premote a long(er) (and a more dust-free) "chip life".

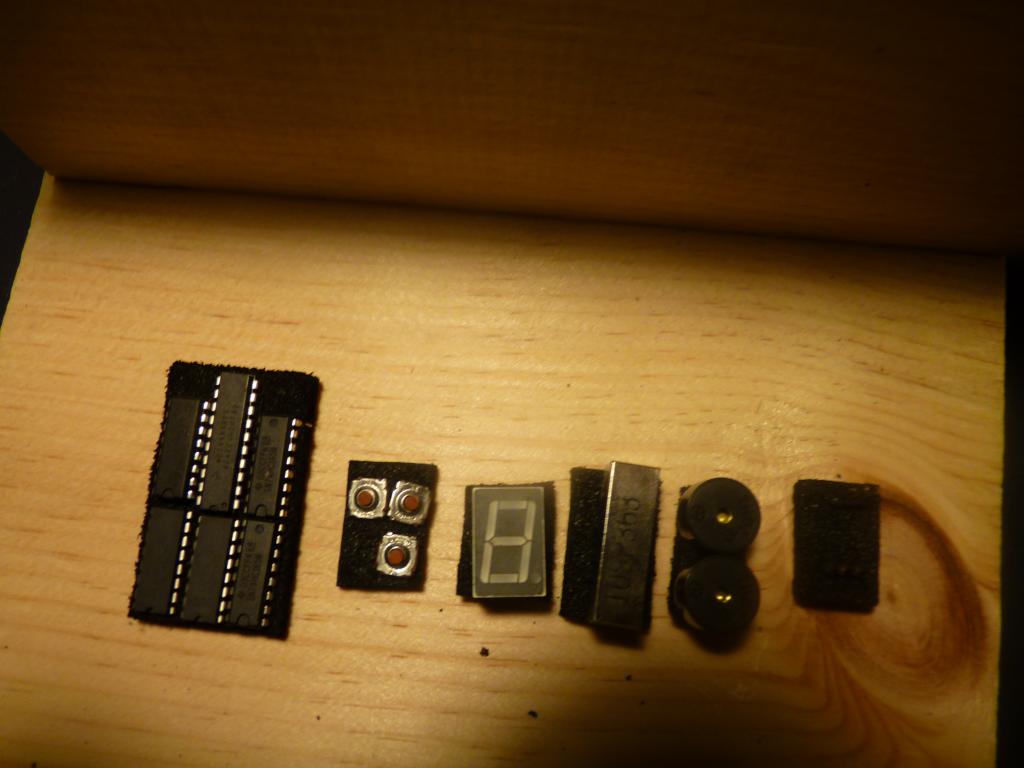

Now, on to the conductive foam. All of Parallax's ICs are shipped in (black) conductive foam. The foam has so many uses. It can be used to (going LEFT to RIGHT in the picture) hold ICs, store butons, seven segments, small relays, piezo elements, and those pesky three pin headers!!! DOWN with bent or snapped of pins!! YAY for CONDUCTIVE FOAM!!!!!!

pictures are in attatchments

DON'T THROW THOSE BAGS AWAY!!!!!!!!!!!!!

(I THINK I emphasized that enough)

Those bags have other uses. For example you could store your ICs in one of the antistatic bags to premote a long(er) (and a more dust-free) "chip life".

Now, on to the conductive foam. All of Parallax's ICs are shipped in (black) conductive foam. The foam has so many uses. It can be used to (going LEFT to RIGHT in the picture) hold ICs, store butons, seven segments, small relays, piezo elements, and those pesky three pin headers!!! DOWN with bent or snapped of pins!! YAY for CONDUCTIVE FOAM!!!!!!

pictures are in attatchments

Comments

All I could think of were card rack end supports.

Conductive bags are adaptable to make good electrical shields.

I build/mount prototype circuitry on rectangular cutting boards I buy at the dollar store and use the plastic rails as guides to slide the cutting boards into for storage. Think of it as a rack mount cabinet for projects.

-Phil

Good write-up, Phil, though I'm not sure these kinds of sensors would qualify as measuring force in the broad sense, as it would be pretty hard to determine things like acceleration. I've always described them as tactile pressure sensors. Piezo discs are good examples of true force sensors.

I talked about these in my 1987 book Robot Builder's Bonanza (now in its fourth edition, everyone go out and buy a copy!!), but it was Forrest Mims that I think first wrote up the concept in one of his Poptronics articles from the late 70s. Forrest has always had an eye for out-of-the-box thinking.

-- Gordon

Actually piezo disks measure a change in force. They do not produce a DC voltage with a static force applied. You can, of course, integrate the output, but drift can be an issue.

-Phil

I can't say I have tried it myself so I am not sure it would work, but you might try "Silver Print" or conductive epoxy to attach braided wire to the bag. I have used Silver Print to produce a conductive coat for an alpha/beta particle detector. It is a conductive paint of about the same consistency as nail polish. Even comes with a similar applicator brush.

PS, I am curious as to what you would be detecting with that if you don't mind sharing it.

I could get good measurements using normal plastic vials only if I made a Faraday cage for them by wrapping them in aluminum foil. One of the many problems with using foil was the fear of losing small pieces of the foil before an experiment was over making the original tare weight no longer valid.

Some of those anti-static vials behaved as well as metal in/on (it's enclosed in a draft guard) the balance.

You can also use the black foam as pads on the claw of a robot arm to sense how tight of a grip it has on something. There was an article in one of the electronics magazines(N&V?) about this.

I also think the black foam would be good to use on the feet of hexapods and other robots to sense how the weight is distributed.

Let's see . . . You could use a big piece inside your pillow case and use a data logger to see how often you toss and turn.

I think I read where someone made slippers with force sensing to use as a foot controlled mouse. Good bye carpal tunnel, hello some new ankle syndrome.

Use the black foam inside gloves and make them a controller for a boxing game.

Instead of carpet padding for full coverage intruder alarm.

A soft piano.

Okay, I'll stop now. I keep meaning to experiment with the stuff (black foam) but there is always some other project more pressing.

Oh, one more. I keyboard for your cat.

Besides electronic parts storage, I purchased a large sheet so I'd have enough for the above mentioned experiments.

Too bad I don't have a cat to test out my feline keyboard.

Duane

What I mean by "attachable" is that any conductive element in the bag can't be connected to. There's infinite resistance on the surface of the bag, so conductive sprays, cements, tapes, nickel print, or whatever won't work.

Two large conductive layers placed together with an insulator inbetween makes a capacitor, which is another nice sensing material. I've made these out of large, thin sheets of copper with non-conductive compressible foam between, but it would be nice to find something as "magical" as conductive foam.

I'm guessing the conductive material in these bags is so scant they're not suitable for this type of thing. Wikipedia says they work as Faraday cages, so they don't actually need to be electrically conductive with the parts they're protecting.

Somebody mentioned conductive rubber: there's still some stuff that goes by the brand Zoflex. Can be purchased online, in sheets and paste form. I've never gotten that far. Just drooled over it.

-- Gordon

Certainly not to be a pedant, but I personally classify the conductive foam as pressure sensors rather than force sensors because in addition to measuring basic force, they measure that force across the surface area of the sensor. That's the definition of pressure, right? Force is irrespective of area, but the output of conductive foam is wholly dependent on how large of an area of the foam is being compressed. Fat fingers make a bigger reading than skinny ones, given the same force.

(Or put another way: you should weigh the same on a bathroom scale whether your feet are size 8 or size 14. The amount of surface area on the sensing device should not affect the measurement, unless it's a measurement of pressure, which then considers the force per unit area.)

Contrast that to a piezo disc, where it's the deflection of the whole disc that produces the output. On a micro scale, the area of the force against the disc has some influence. But overall, the disc is merely reacting to the amount of deflection of the disc, and is more accurate as a basic measurement of force.

-- Gordon

Actually, conductive foam is a very bad pressure or force sensor, due to deflection memory. That's why, in my example, I surrounded the small conductive foam dot with something more resilient.

In any event, neither foam nor piezo devices, nor strain gauges respond directly to force or pressure. They respond to deflection. Deflection is to pressure as current is to voltage. How you interpret the readings you get depends on area, resistance, the modulus of elasticity, etc.

-Phil

I'll be tossed out of the choir, but they make great back-scratchers! (If long enough...)

--Rich

-Phil